Ultrasonic loading method of calcium-based desulfurizing agent for coal burning or gasificating desulphurization

A technology of desulfurization agent and coal combustion, which is applied in fuel, solid fuel, petroleum industry, etc. It can solve the problems of limiting the practical application of ion exchange method and loss of calorific value, and achieves good commercial application prospects, no secondary pollution, and simple principle Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0029] Mix 2g of Illinois#6 bituminous coal with a particle size range of 300-1000μm and analytically pure calcium oxide fine particles (<75um) according to Ca / S=0.5, 1, 1.5, 2.4, put the mixture into 100ml deionized water, and put the sample at room temperature Ultrasonic treatment for 2 hours, ultrasonic power 150W, frequency 20kHz, then filter the calcium-containing coal powder mixture, and dry in a constant temperature oven at 60°C for 12 hours under the protection of nitrogen to obtain a calcium-containing coal powder sample. 200 mg of different samples were taken respectively and put into a fixed bed reactor, the reactor air flow was 10% (volume fraction) oxygen+nitrogen, and the samples were burned under slow heating conditions. The reactor was heated from room temperature with a heating rate of 10°C / min, the final temperature was 800°C, and the holding time was 30 minutes.

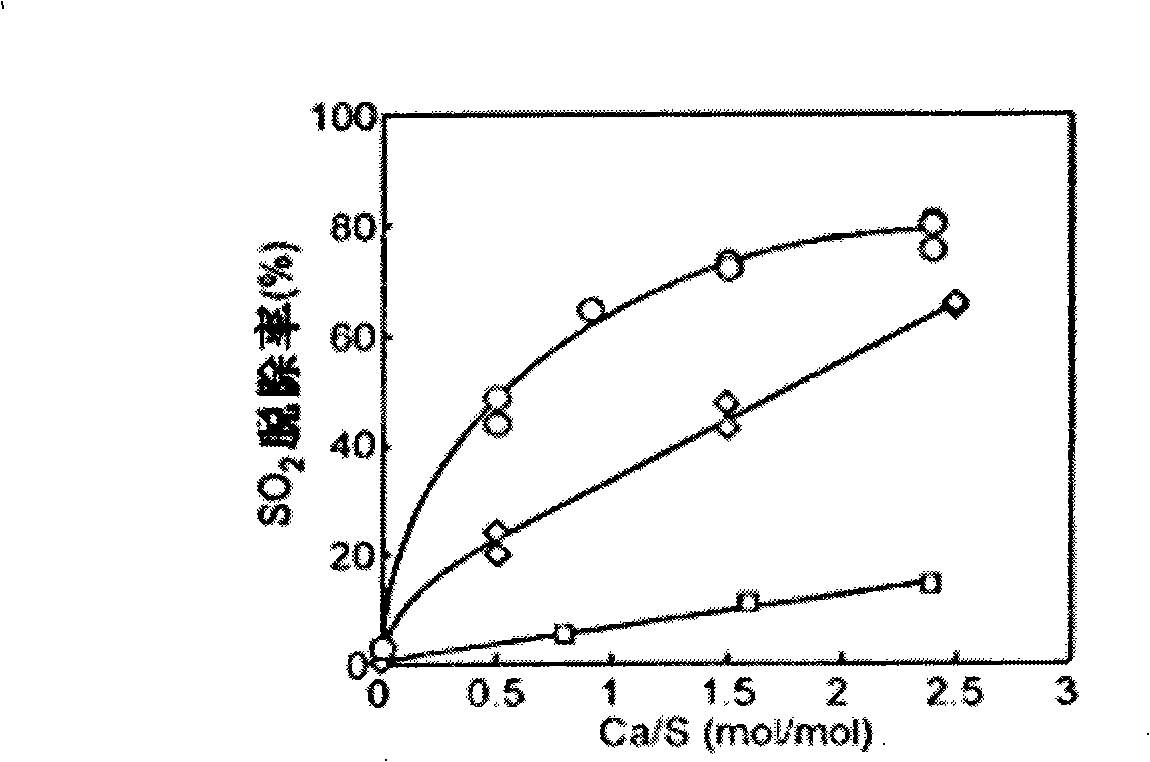

[0030] Experimental desulfurization effect as figure 1 , the experiment compared the desulfuri...

Embodiment 2

[0033] Mix 2g of Illinois#6 bituminous coal with a particle size range of 300-1000μm and analytically pure calcium oxide fine particles (<75um) according to Ca / S=0.5, 1.5, 2.4, put the mixture into 100ml deionized water, and ultrasonicate the sample at room temperature 2h, ultrasonic power 300W, frequency 30kHz, then filter the calcium-containing coal powder mixture, and dry it in a constant temperature drying oven at 90°C for 18 hours under the protection of nitrogen to prepare a calcium-containing coal powder sample. 200 mg of different samples were taken respectively, and put into a fixed-bed reactor with the same atmosphere as described in Example 1, and the temperature of the reactor was maintained at 800°C. The sample burns rapidly in the reactor for a duration of 15 minutes.

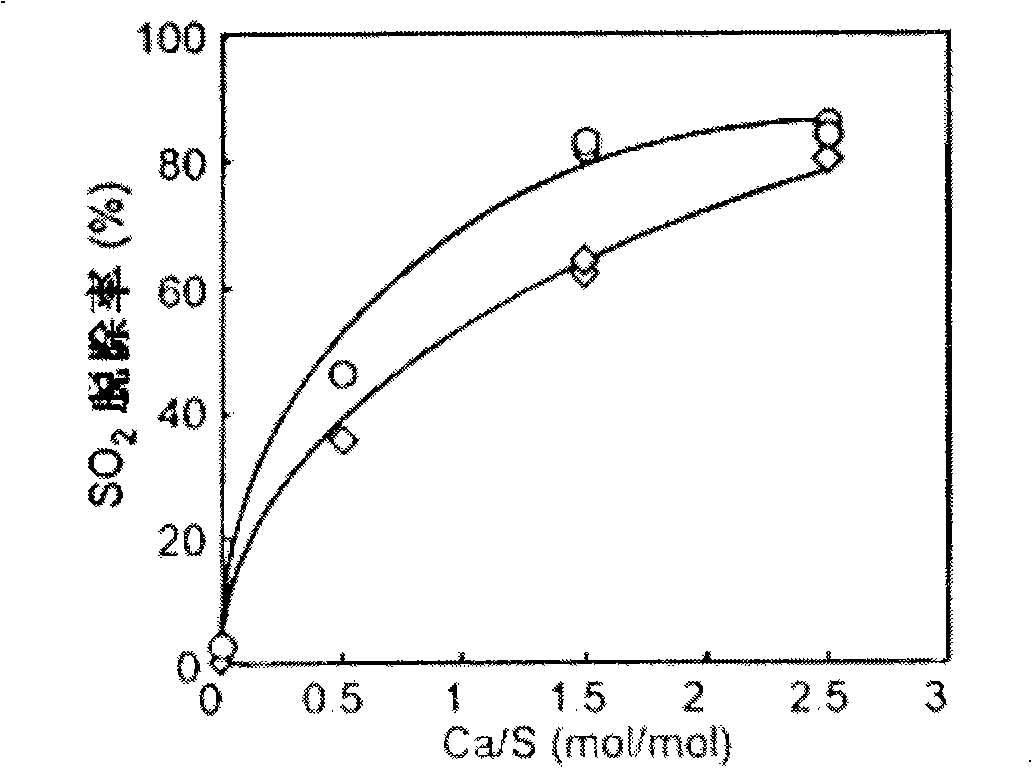

[0034] Experimental desulfurization effect as image 3 , the experiment compared the desulfurization effect of the ultrasonic calcium-based loading method and the mechanical stirring hydration meth...

Embodiment 3

[0036] Mix Illinois#6 bituminous coal and calcium oxide fine particles according to Ca / S=1.5, put the mixture into 100ml deionized water, and treat the sample with ultrasonic at room temperature, ultrasonic power 150W, frequency 40kHz, treatment time 1h, 2h and 3h respectively. Then the calcium-containing coal powder mixture was filtered, and dried in a constant temperature drying oven at 75° C. for 15 hours under the protection of nitrogen to obtain a calcium-containing coal powder sample. 200 mg of different samples were taken respectively, put into a fixed-bed reactor, and burned under the same slow heating conditions as described in Example 1. The desulfurization efficiencies of the samples tested at different treatment times were 59% (1h), 61% (2h), and 71% (3h).

PUM

| Property | Measurement | Unit |

|---|---|---|

| size | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com