High modulus asphalt concrete and method for preparing same

A kind of asphalt concrete, high modulus technology, applied in the direction of sustainable waste treatment, solid waste management, climate sustainability, etc., can solve the problems that the performance cannot meet the road use, immaturity, etc., reduce the bending and tensile strain, improve the road performance effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

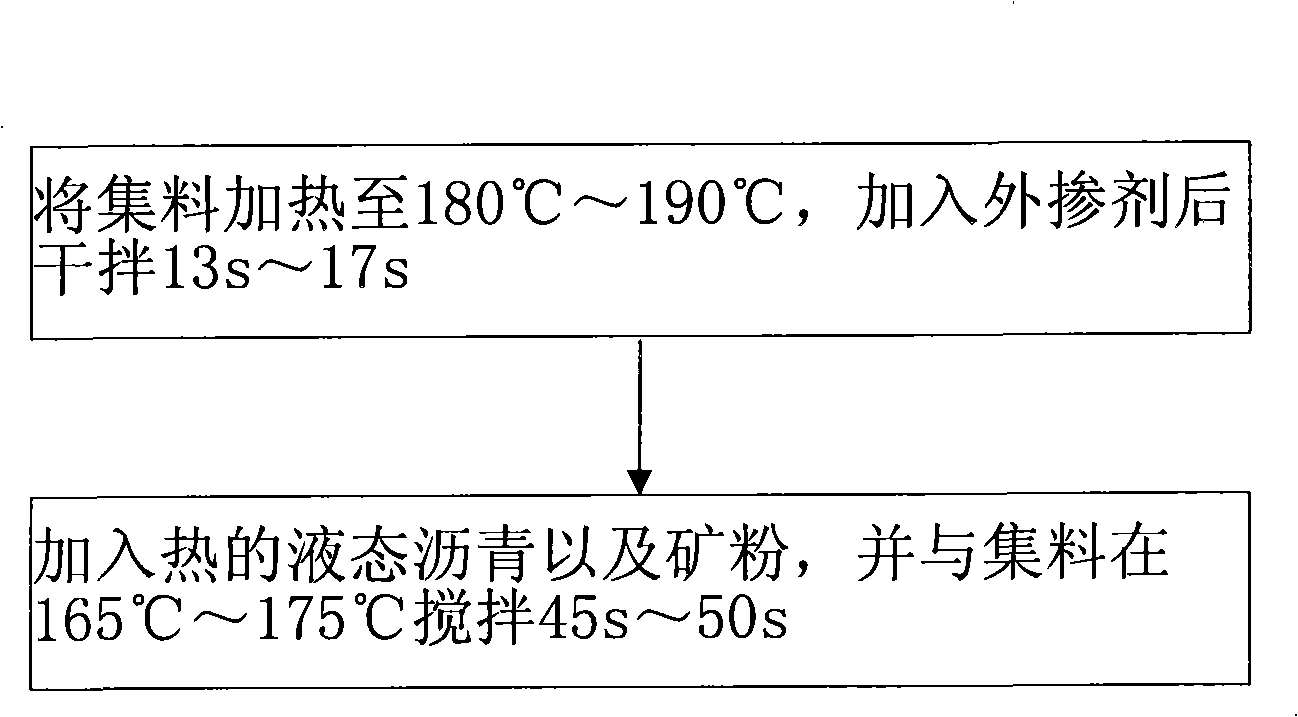

Method used

Image

Examples

Embodiment 1

[0044] Example 1. Effect of powder-to-glue ratio on the high-temperature performance of asphalt mortar

[0045] Raw materials:

[0046] (1) Asphalt: Karamay AH-90 asphalt (Xinjiang Karamay Oil Refinery) whose technical indicators meet the requirements of standard A-grade asphalt is used.

[0047] (2) Mineral powder: Jingyang limestone mineral powder, its apparent density is 2.778g / cm 3 .

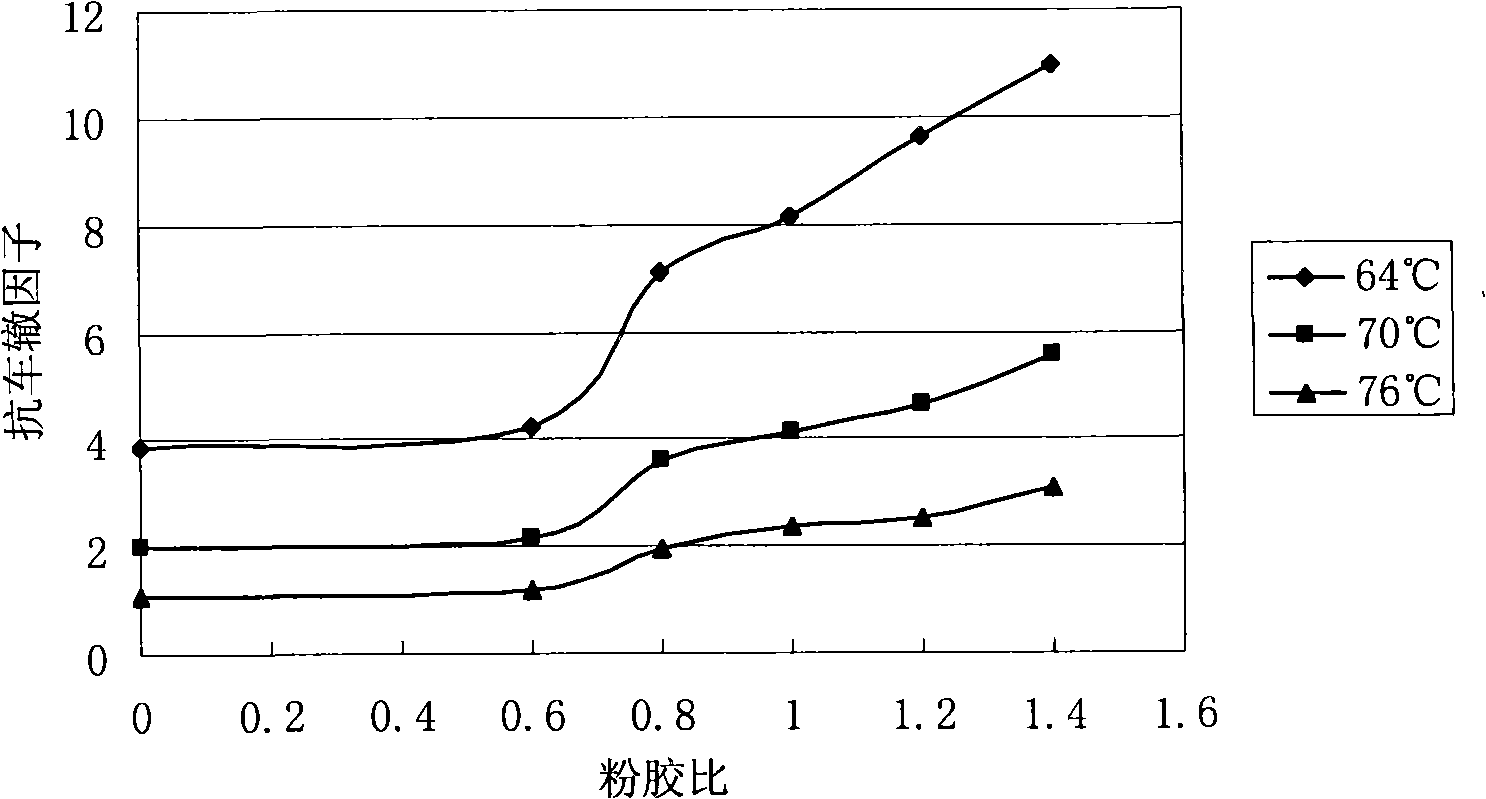

[0048] Mineral powder was used as filler, and asphalt mortar was prepared according to five different powder-to-glue ratios of 0.6, 0.8, 1.0, 1.2, and 1.4, and the dynamic shear rheological test (DSR) in the asphalt binder performance specification of the US SHRP program was used to test the The high temperature performance of asphalt mortar was tested and evaluated. See the test results figure 2 .

[0049] From figure 2 It can be seen from the figure that the index reflecting the high temperature performance of asphalt mortar—the rutting factor G * / sinδ increases significantly wit...

Embodiment 2

[0050] Example 2. Effect of powder-to-glue ratio on the low-temperature performance of asphalt mortar

[0051] The starting materials are the same as in Example 1.

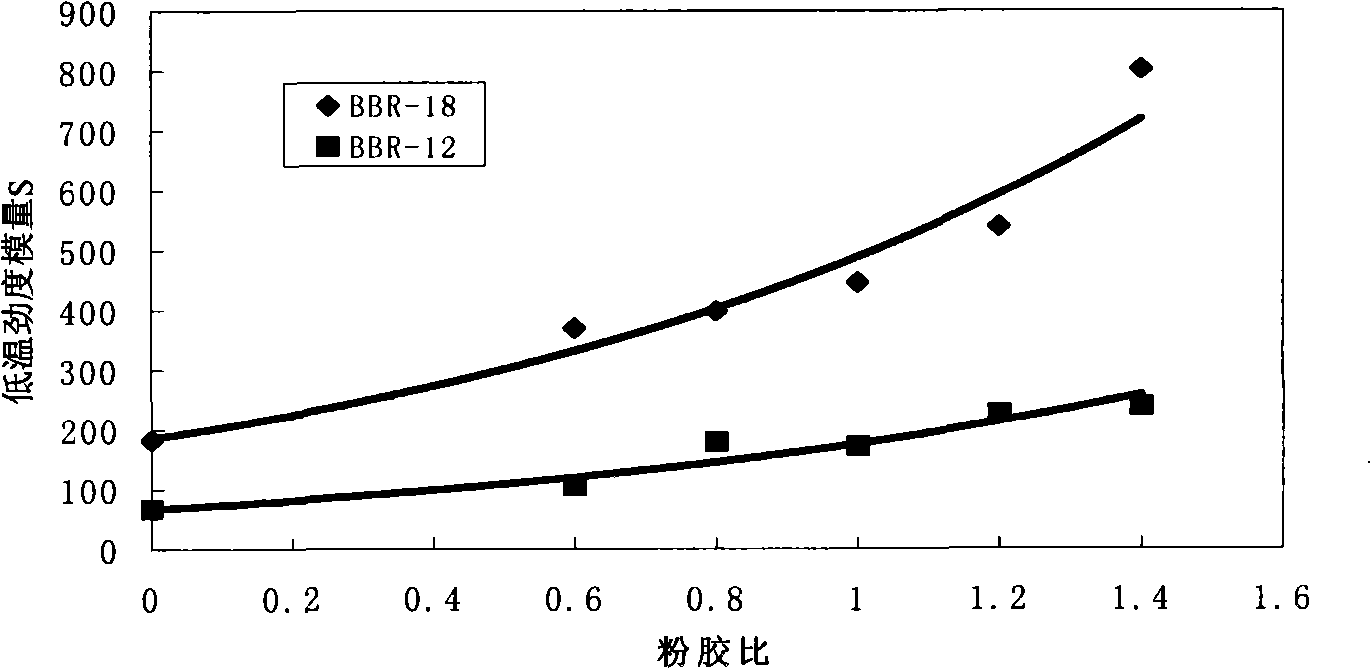

[0052] Mineral powder was used as filler, and asphalt mortar was prepared according to five different powder-to-glue ratios of 0.6, 0.8, 1.0, 1.2, and 1.4, and the bending beam rheological test (BBR) was used to test the asphalt The performance of the glue at -12°C and -18°C was tested and evaluated. The test results are shown in Figure 3.

[0053] The results in Fig. 3 show that as the powder-to-binder ratio increases, the stiffness modulus S reflecting the low-temperature performance of asphalt mortar increases gradually, and the creep rate m decreases slightly. It shows that the low-temperature crack resistance of the mortar decreases slightly with the increase of the powder-to-glue ratio, especially when the powder-to-glue ratio exceeds 1.0, this downward trend is more obvious. This is because after the add...

Embodiment 3

[0054] Example 3. Effect of polymer external admixture on compressive strength and modulus of resilience of AC-20 type asphalt mixture

[0055] Raw materials:

[0056] (1) Aggregate: Clean, hard and wear-resistant Xingyang limestone aggregates are used, and its technical indicators meet the requirements of the normative standards.

[0057] (2) Asphalt: Korean SK-70 asphalt (Korean SK Group) whose technical indicators meet the requirements of standard A-grade asphalt is used.

[0058] (3) Mineral powder: Queshan limestone, the apparent density is 2.682g / cm 3

[0059] (4) Polymer external dopant: PR Module high modulus additive (French PRI company), its various technical indicators are shown in Table 1.

[0060] Table 1

[0061] nature

unit

value

color

-

grey

mm

5

density

g / cm3

0.93~0.965

℃

175

mm

0 / 5

[0062] Mineral material gr...

PUM

| Property | Measurement | Unit |

|---|---|---|

| density | aaaaa | aaaaa |

| density | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com