Full-degradation salt large packing material and preparation method

A fully degradable, large packaging technology, applied in the field of packaging materials, to achieve the effects of good durability, beautiful appearance, easy printing and high precision

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

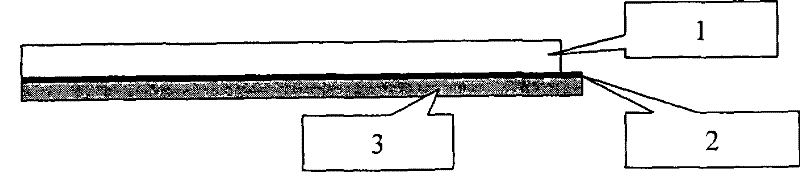

[0022] Take non-toxic polypropylene and calcium carbonate degradable masterbatch with a weight ratio of 72:28 and evenly mix them. After conventional hot-melt, drawing, and weaving into woven fabric 1, the weight of woven fabric 1 is 72g / m 3 ; In addition, the non-toxic polyethylene and calcium carbonate degradation masterbatch with a weight ratio of 70:30 are evenly mixed, heated to become a liquid, and then the liquid is evenly poured on the base woven cloth 1 by a general coating method to form a high Molecular film 2, surface 2 of polymer film and synthetic paper 3 are rolled and heat-bonded to form the final product.

[0023] The model using non-toxic polypropylene is F401 (Yangzi Petrochemical Co., Ltd.), the particle size is 4.5mm, and the density is 0.93g / cm 3 , the melt index is 2.5~3.5g / 10min; the calcium carbonate degradation masterbatch model is MEF0690CB (Guangxi Luxin Environmental Protection Technology Co., Ltd.), the particle size is 2.5mm, and the density is 1...

Embodiment 2

[0025] Take non-toxic polypropylene and calcium carbonate degradable masterbatch with a weight ratio of 85:15 and mix them evenly. After conventional hot-melt, wire drawing, and weaving into woven fabric 1, the weight of woven fabric 1 is 70g / m 3 In addition, the non-toxic polyethylene and calcium carbonate degradation masterbatch with a weight ratio of 85:15 are evenly mixed, heated to become a liquid, and then the liquid is evenly poured on the base woven cloth 1 by a general-purpose coating method to form a polymer Film 2, the polymer film 2 side and the synthetic paper 3 treatment side are rolled and heat-bonded to form the final product.

[0026] The model of non-toxic polypropylene is T305, the particle size is 4.5mm, and the density is 0.93g / cm 3 , the melt index is 2.5~3.5g / 10min; the calcium carbonate degradation masterbatch model is MEF0690CB, the particle size is 2.5mm, and the density is 1g / cm 3 , the melt index is 0.7g / 10min, and the degradation induction period ...

Embodiment 3

[0028] Take non-toxic polypropylene and calcium carbonate degradable masterbatch with a weight ratio of 80:20 and mix them evenly. After conventional hot-melt, drawing, and weaving into woven fabric 1, the weight of woven fabric 1 is 60g / m 3 , then take the non-toxic polyethylene and calcium carbonate degradation masterbatch with a weight ratio of 82:18 and the non-toxic polyethylene dark-colored light-proof masterbatch accounting for 3% of the total weight of the non-toxic polyethylene and calcium carbonate degradation masterbatch, mix evenly, and heat It turns into a liquid, and then the liquid is uniformly and hotly poured on the base woven fabric 1 to form a polymer film 2 by using a general film coating method, and the polymer film 2 surface is rolled and heat-bonded with the synthetic paper 3 treatment surface to form the final product. The polymer film thickness is 0.07mm.

[0029] The model using non-toxic polypropylene is T300 (Shanghai Petrochemical Co., Ltd.), the p...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| density | aaaaa | aaaaa |

| melt flow index | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com