Fluid packing forming device and method thereof

A molding device and molding method technology, applied in packaging, transportation packaging, transportation and packaging, etc., can solve the problems of increase, decrease, labor consumption, etc. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

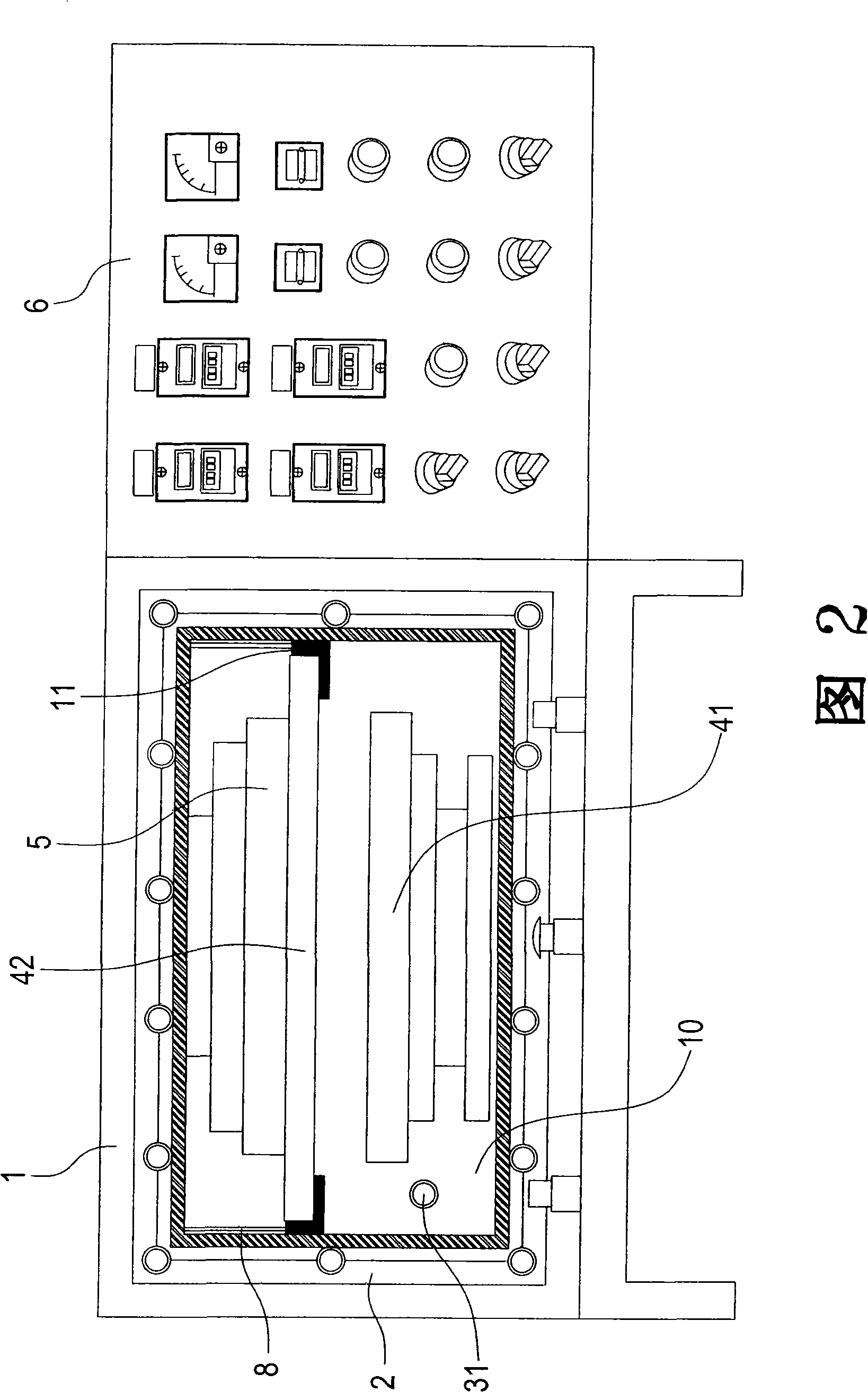

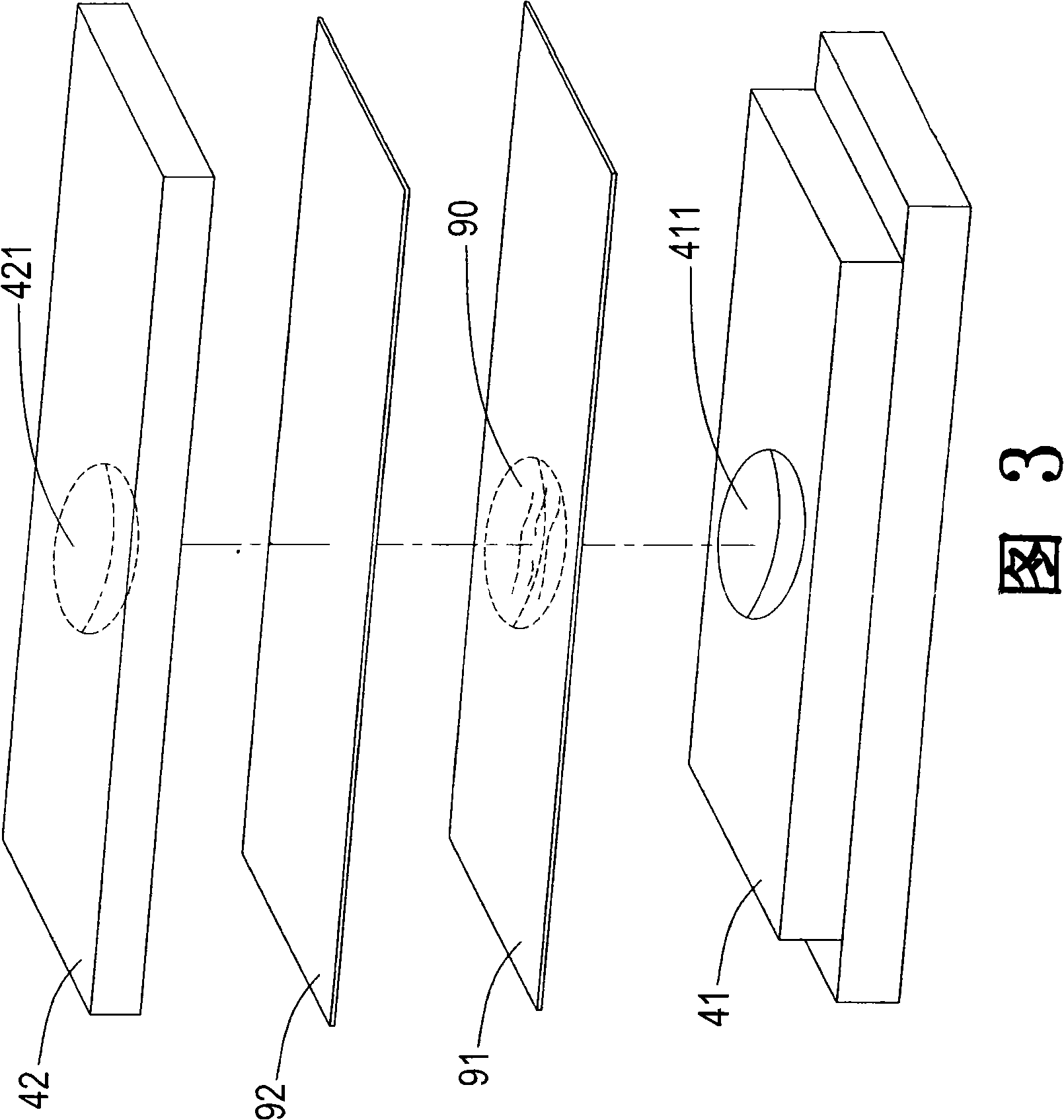

[0044] As shown in FIG. 1 and FIG. 2 , it is a fluid encapsulation molding device disclosed in the present invention.

[0045] The fluid encapsulation molding device includes: machine base 1, valve 2, vacuum pump unit 3, lower mold base 41, middle mold base 42, sealing base 5, and operation module 6.

[0046] The base 1 is a box structure with a vacuum cavity 10 and a support frame 11 is arranged in the vacuum cavity 10 .

[0047] The valve 2 and the closed base 1 can make the vacuum cavity 10 form a closed state, so as to block the vacuum cavity 10 from the external space.

[0048] The vacuum pump unit 3 is connected to the vacuum chamber 10 and is provided with at least one air hole 31, which is used to discharge the gas in the vacuum chamber 10 to form a near-vacuum state, and can send gas into the vacuum chamber 10 to release the near-vacuum state .

[0049] In addition, the vacuum pump unit 3 can also be provided with a plurality of air holes 31, one of which is dedicat...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com