Acarbose chewable tablets and preparation method thereof

A technique for acarbose and chewable tablets, which is applied in the field of chewable tablets containing acarbose as an active ingredient and its preparation, can solve the problems of easy moisture absorption and poor taste, and achieve moisture resistance, stable drug effect, and convenience carrying effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

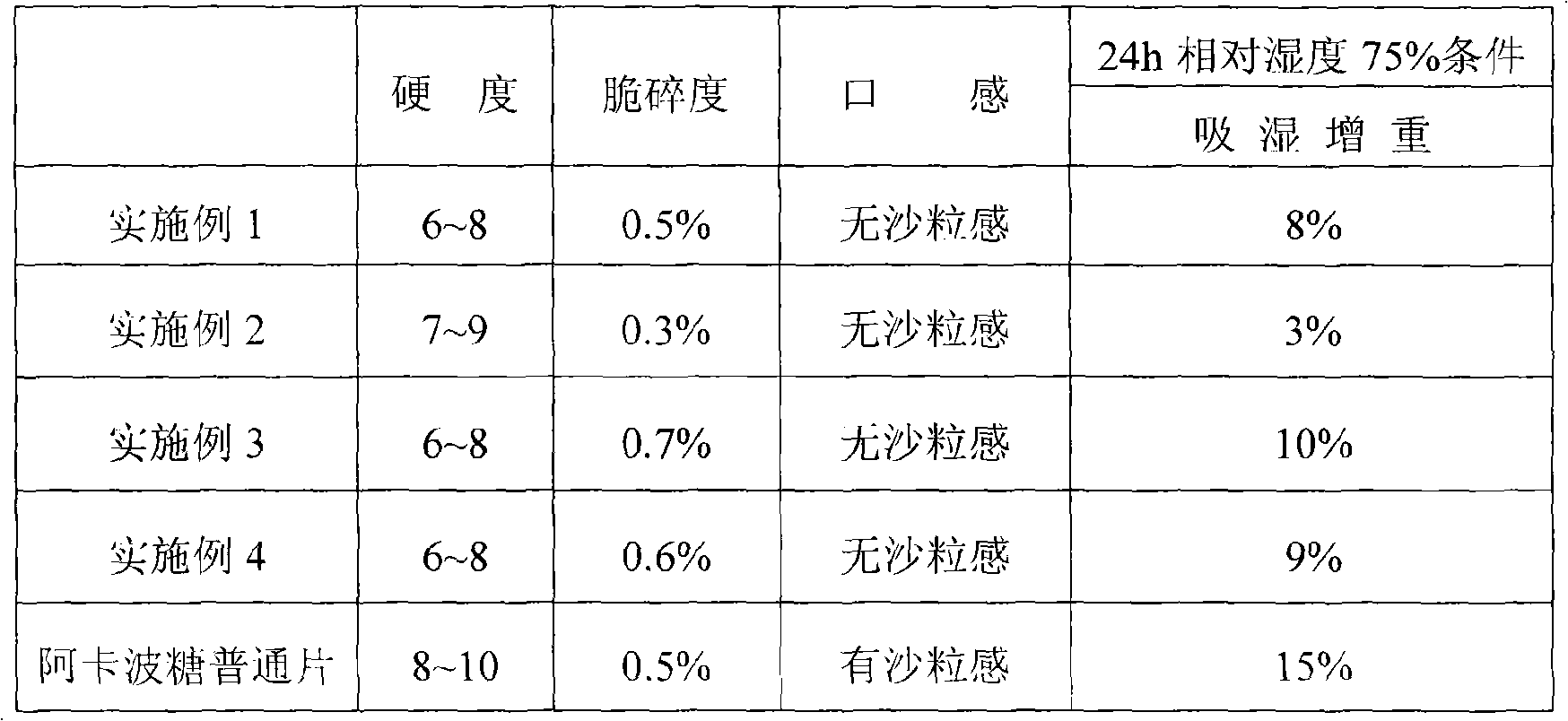

Examples

Embodiment 1

[0029] prescription:

[0030] Acarbose 50g

[0031] Sorbitol 90g

[0032] Microcrystalline Cellulose 20g

[0033] 5% polyethylene glycol ethanol solution appropriate amount

[0034] Pineapple Flavor 4g

[0036]

[0037] Made into 1000 pieces

[0038] The raw and auxiliary materials of the above-mentioned prescription amount were weighed and passed through 80 mesh sieves respectively, polyethylene glycol was prepared into a 5% solution with ethanol for later use, acarbose, sorbitol, and microcrystalline cellulose were mixed evenly, and an appropriate amount of 5% polyethylene glycol was added. Ethylene glycol ethanol solution is used to moisten the material so that the material reaches the state of "agglomeration when grasped and disperse when touched", that is, it is made into a soft material, granulated through a 20-mesh sieve, dried at 45°C, and then granulated through a 24-mesh sieve. The dry granules are mixed w...

Embodiment 2

[0040] prescription:

[0041] Acarbose 50g

[0042] Mannitol 350g

[0043] 5% ethyl cellulose ethanol solution appropriate amount

[0044] Micronized silica gel 4g

[0046]

[0047] Made into 1000 pieces

[0048] The raw and auxiliary materials of the above-mentioned prescription amount were weighed and passed through 80 mesh sieves, and prepared into 5% ethyl cellulose ethanol solution for use. Acarbose, mannitol, and microcrystalline cellulose were mixed evenly, and an appropriate amount of 5% ethyl cellulose was added. Moisten the cellulose ethanol solution to make the material reach the state of "agglomerate when grasped and disperse when touched", that is, it is made into a soft material, granulated through a 20-mesh sieve, dried at 60°C, and then granulated through a 24-mesh sieve. The dry granules are mixed with micronized silica gel and magnesium stearate, mixed evenly, and then compressed into capsule-sh...

Embodiment 3

[0050] prescription:

[0051] Acarbose 50g

[0052] Mannitol 700g

[0053] Microcrystalline Cellulose 200g

[0054] Micronized silica gel 20g

[0057]

[0058] Made into 1000 pieces

[0059] Weigh the raw and auxiliary materials of the above prescription amount, pass through 80-mesh sieve respectively, mix acarbose, mannitol, microcrystalline cellulose, micropowder silica gel, and monascus pigment evenly, then add magnesium stearate, mix evenly, and then directly press into diamond-shaped slices.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com