Three-layer type heat insulation decoration composite panel

A technology of composite boards and decorative boards, applied in the direction of covering/lining, construction, building construction, etc., can solve the problems of poor quality of thermal insulation wall panels, poor thermal insulation performance, and inconvenient construction, so as to achieve stable and reliable quality, shorten construction period, reduce The effect of material waste

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

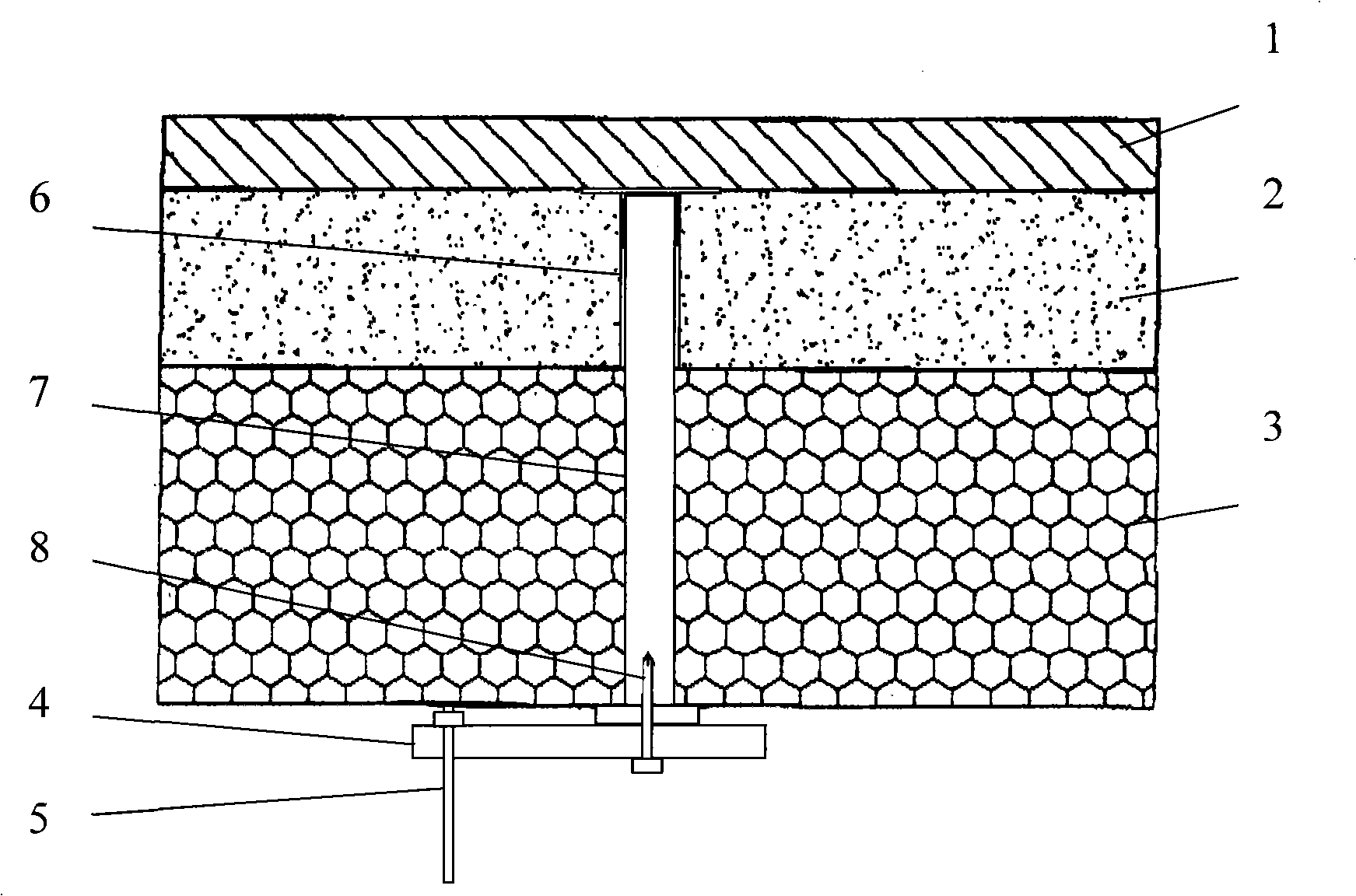

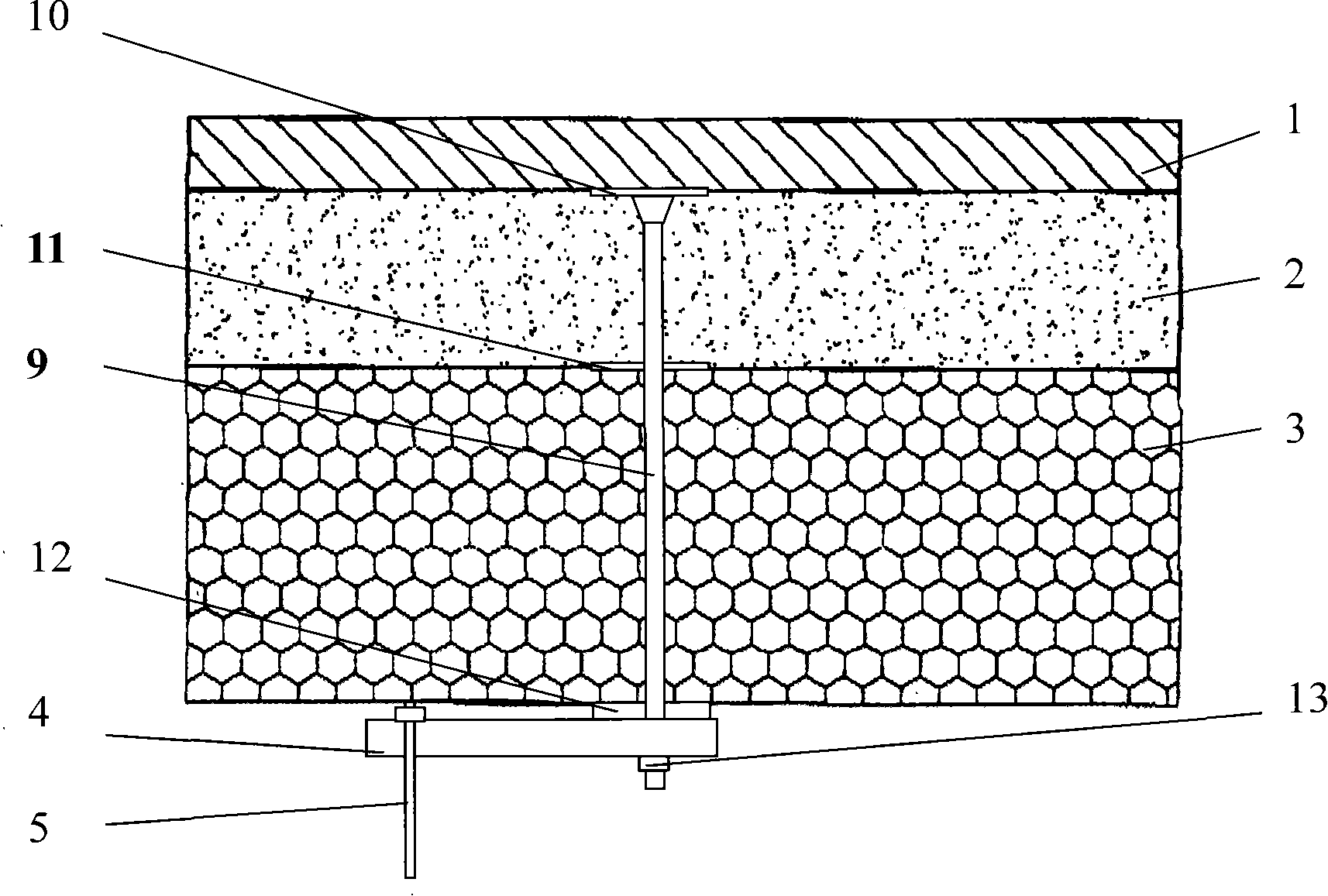

[0019] Such as figure 1 figure 2 As shown, the three-layer thermal insulation and decorative composite board includes a surface layer 1, an intermediate layer 2 and a bottom layer 3, the surface layer is a decorative board layer, the middle layer is a polyurethane foamed gel layer, and the bottom layer is a foam material layer. The board layer is closely bonded together by the polyurethane foamed colloid layer and the foamed material layer to form a three-layer thermal insulation and decorative composite board.

[0020] The foamed colloidal layer is made of isocyanate (referred to as black material) and vegetable oil polyether polyol (referred to as white material) in a ratio of 1:1 to form a foam gel after mixing and stirring, and the foam gel is poured into the surface layer In the middle of 1 and the bottom layer 3, after a certain period of time at normal temperature or under heating, the styrofoam will automatically foam to bond the surface layer and the bottom layer, a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com