Compensating metal oxide semiconductor image sensor and manufacturing method thereof

An oxide semiconductor and image sensor technology, which is applied in semiconductor/solid-state device manufacturing, semiconductor devices, semiconductor/solid-state device components, etc., can solve problems such as complex processes, improve imaging quality, reduce noise, and improve stability Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

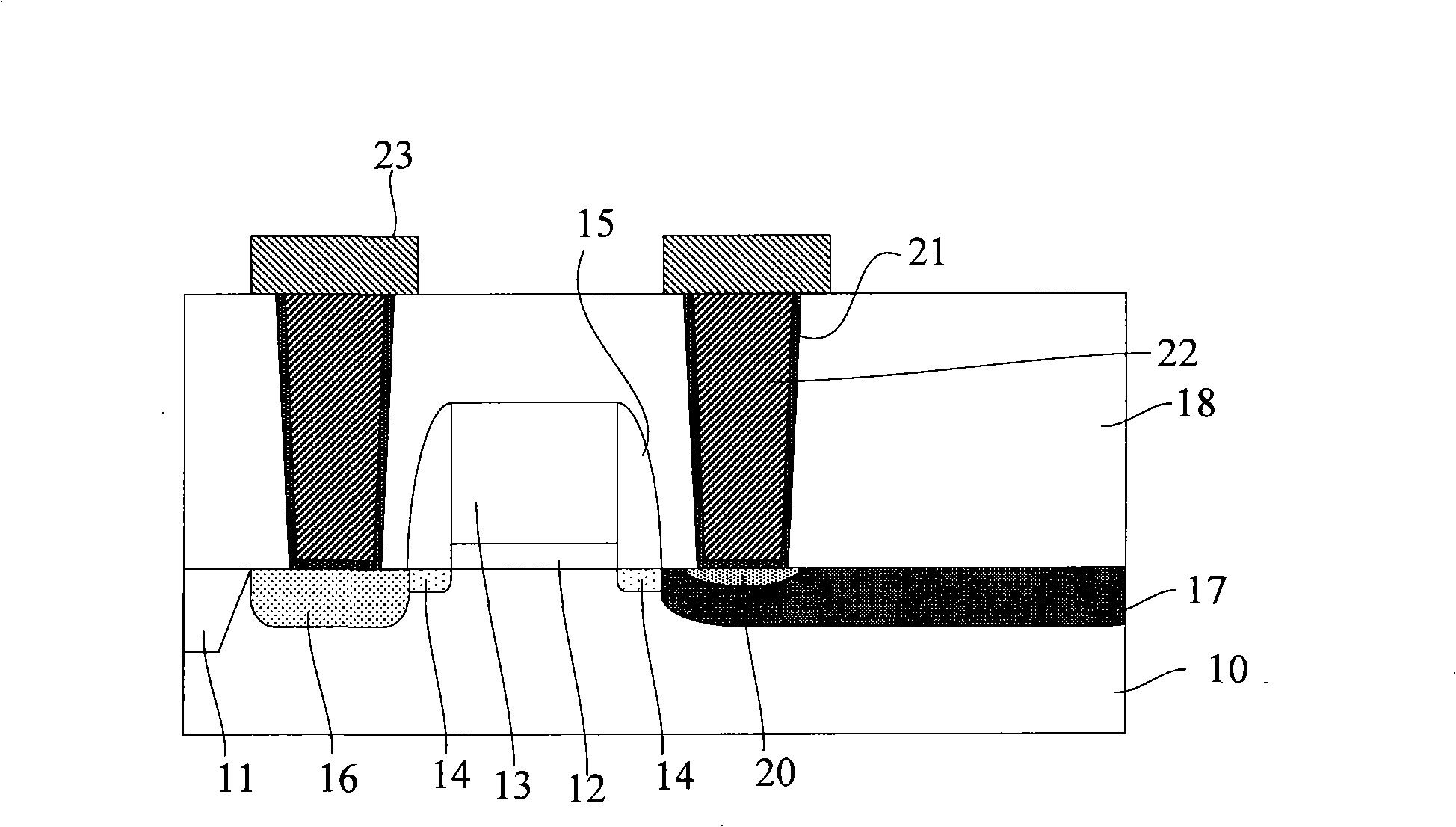

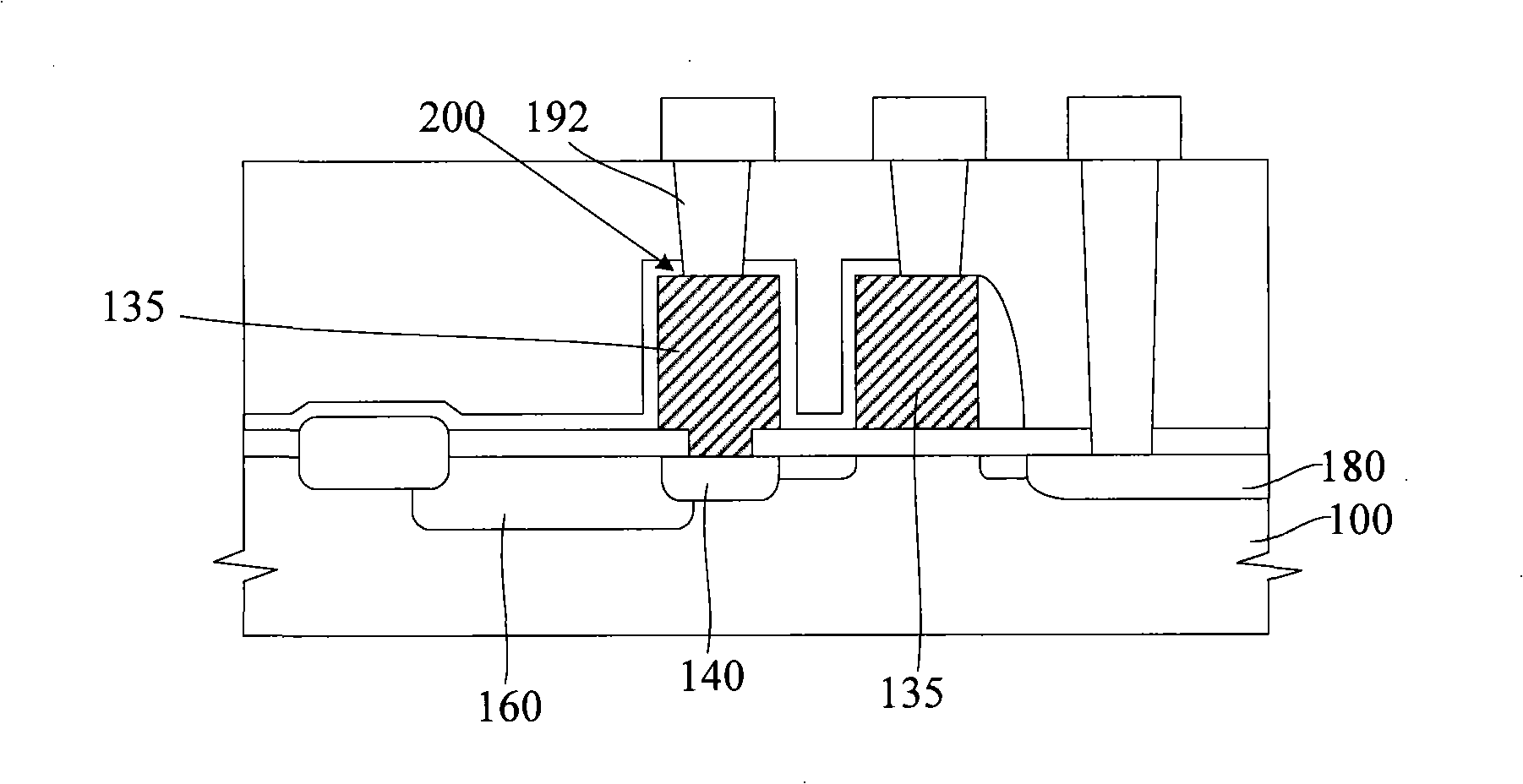

[0038] The specific embodiments of the present invention will be described in detail below in conjunction with the accompanying drawings.

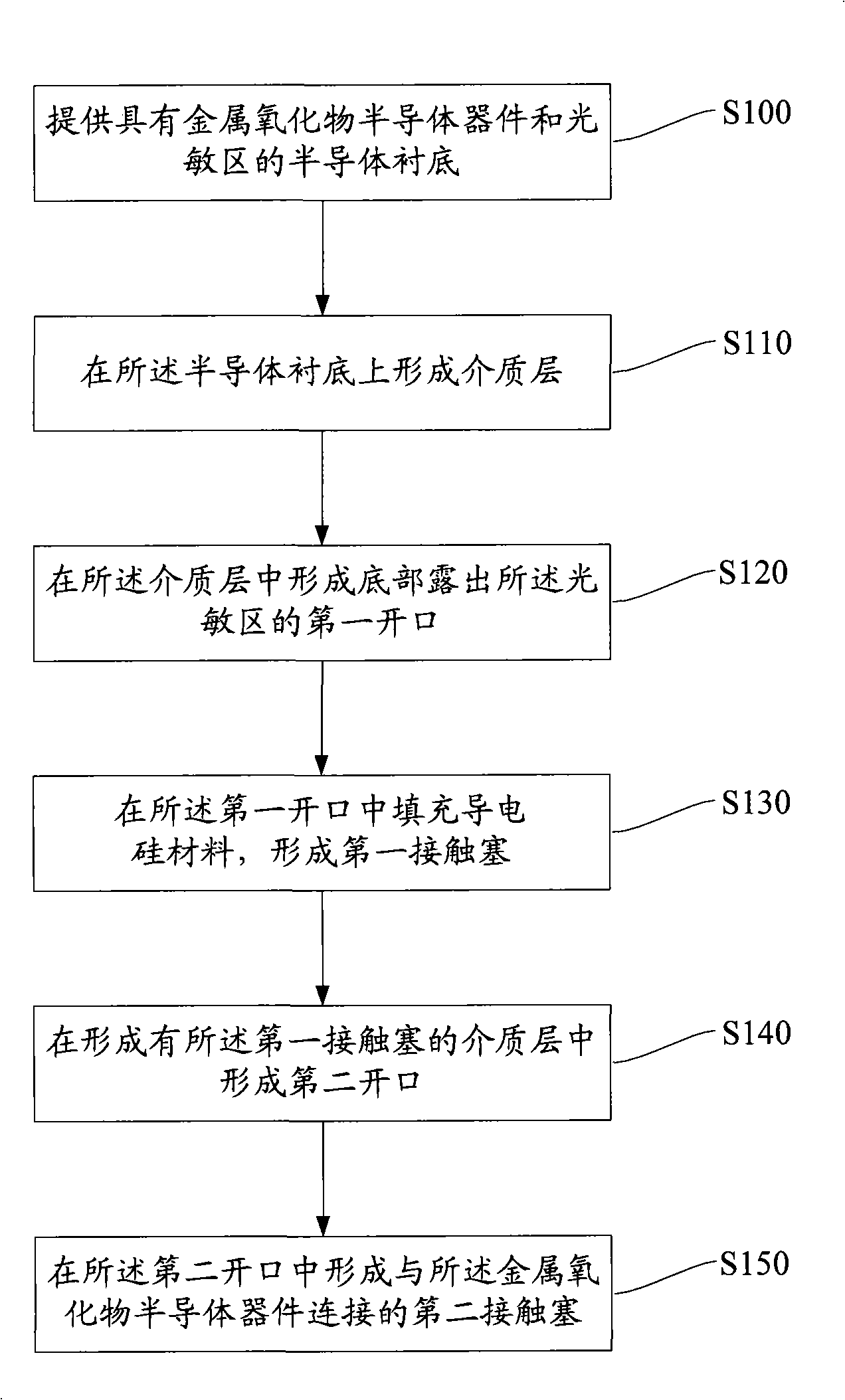

[0039] image 3 It is a flow chart of the first embodiment of the manufacturing method of the CMOS image sensor of the present invention.

[0040] like image 3 As shown, a semiconductor substrate (S100) with a metal oxide semiconductor device and a photosensitive region is provided, and the semiconductor substrate can be a single crystal silicon material or a polycrystalline silicon material;

[0041] forming a dielectric layer on the semiconductor substrate (S110), the dielectric layer may be silicon oxide or other low dielectric constant material, and the method of forming it may be physical vapor deposition or chemical vapor deposition;

[0042] Form a first opening (S120) whose bottom exposes the photosensitive area in the dielectric layer, the method of forming the first opening may be dry etching, in order to reduce the impact of th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com