Multi-way reversing valve of hydraulic device

A technology of multi-way reversing valve and hydraulic device, which is applied in the direction of fluid pressure actuating device, valve device, valve details, etc., can solve the problems of slow reversing speed, low efficiency and large space occupation.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0027] The present invention will be further described below in conjunction with accompanying drawing:

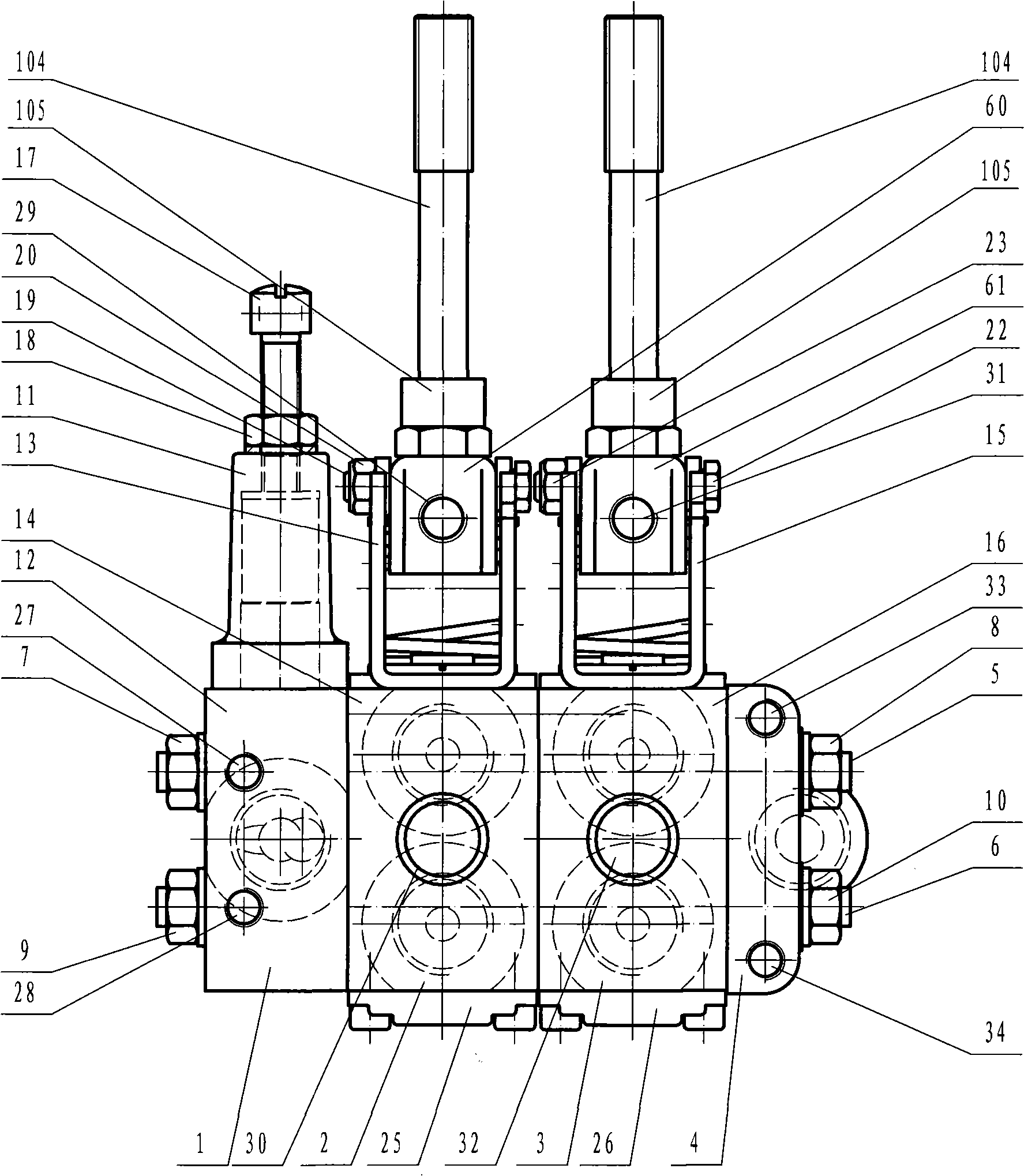

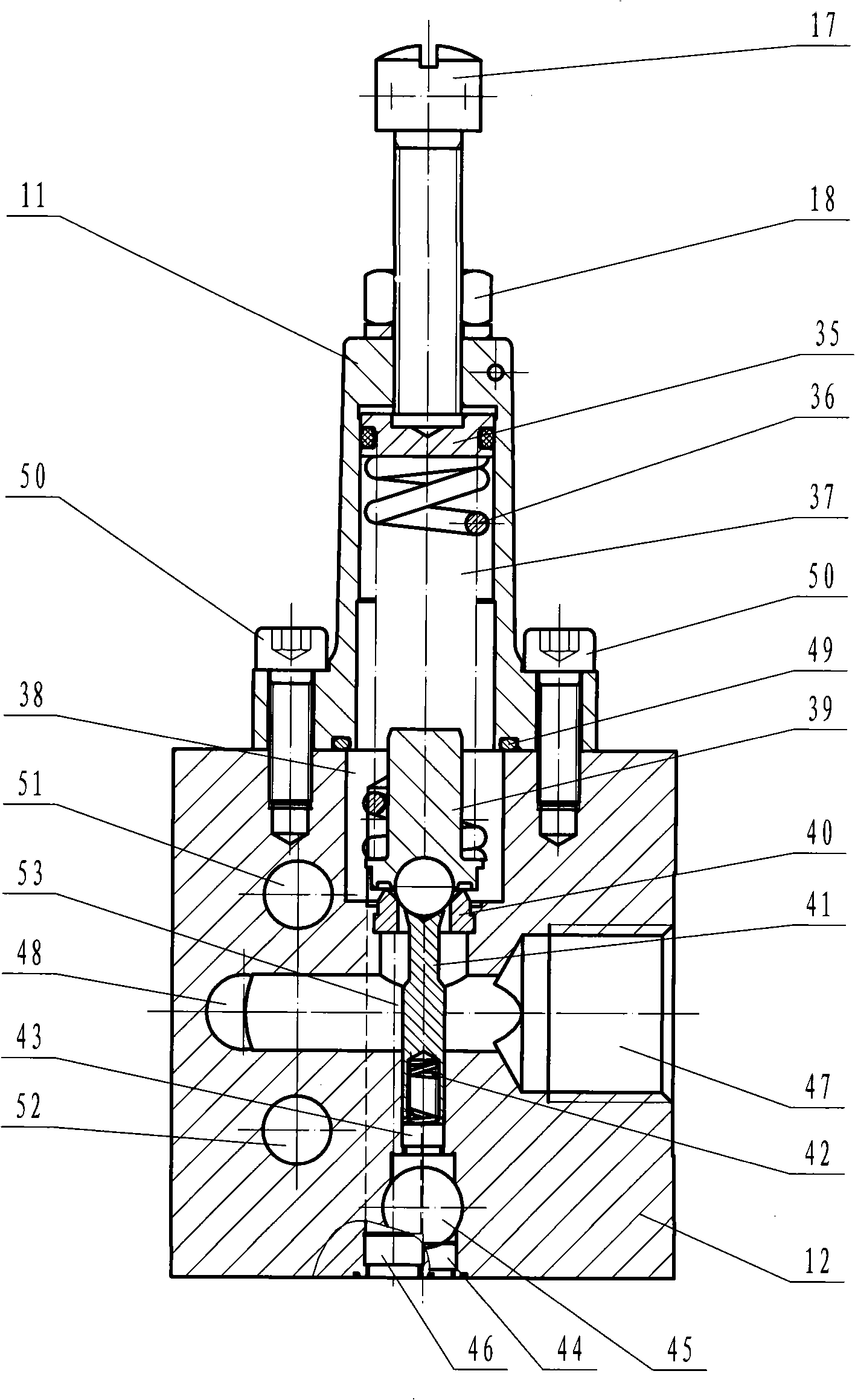

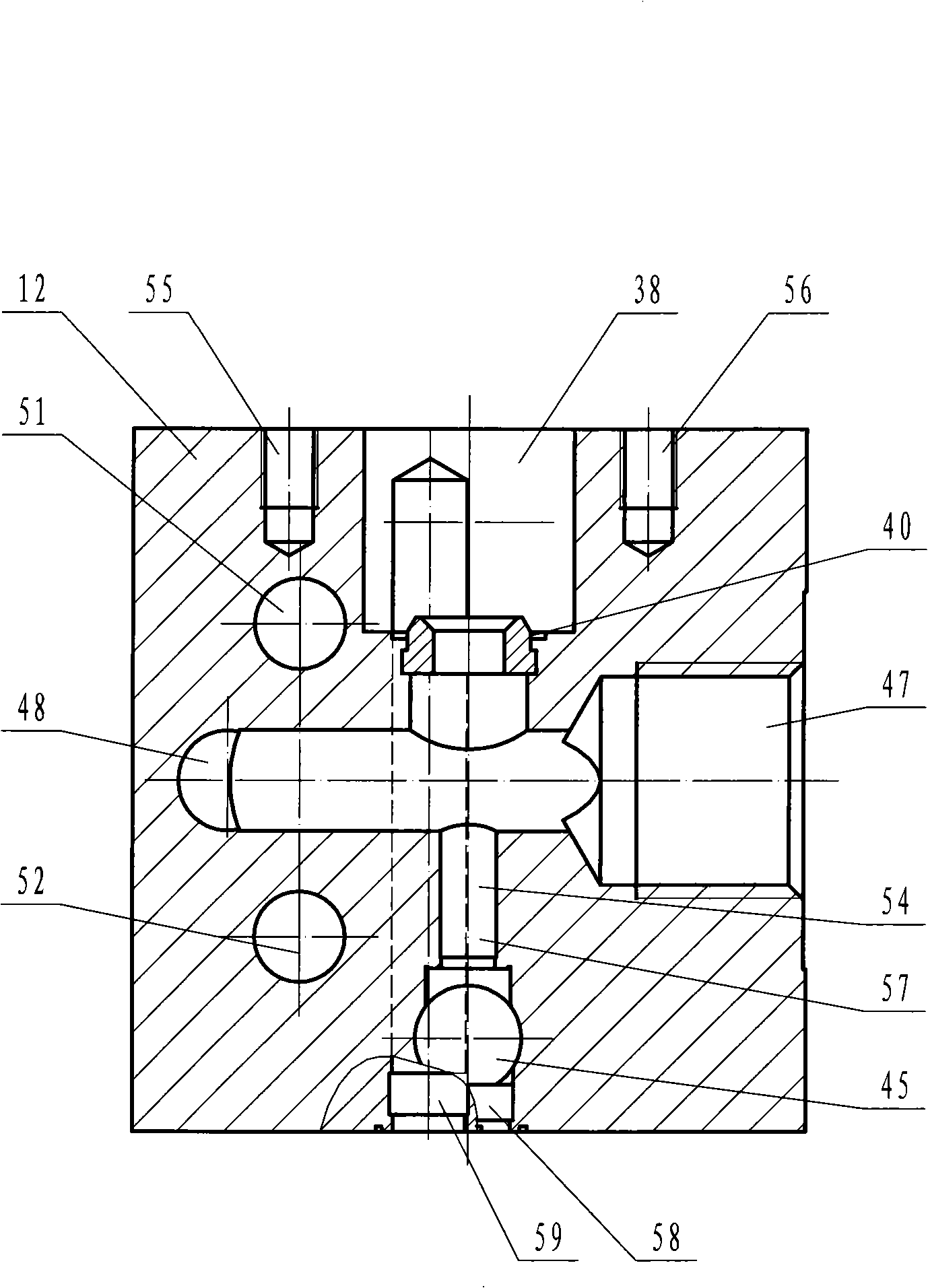

[0028] figure 1 As shown, it is the overall structure diagram, which is composed of liquid inlet valve 1, reversing valve 2, throttle reversing valve 3, and liquid return valve, and is fixed together by studs 5 and 6 in series. Direction and return flow are integrated. The reversing valve adopts the double connection structure of ordinary reversing valve 2 and throttle reversing valve 3. After the hydraulic oil enters the reversing valve, it performs multi-way reversing operation through the joystick 104. The direction principle is:

[0029] Through the joystick 104 installed on the joystick mounting blocks 60, 61, the spool 77 of the reversing valve 2 and the throttle reversing valve 3 can be displaced up and down, so that the hydraulic oil can pass through the outlet 84 or The liquid outlet 85 enters the hydraulic mechanism, so that the mechanism corresponding to the liqu...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com