Alkali lignose concrete air-leading water-reducing agent, preparation and use thereof

A technology of air-entraining water-reducing agent and alkali lignin, which is applied in the fields of building materials and lignin chemistry, and can solve the problem of difficult to achieve high-performance air-entraining water-reducing agent, unsatisfactory air-entraining and water-reducing effects, and water-soluble alkali lignin. problems such as poor performance, achieve significant economic and environmental benefits, reduce segregation and bleeding, and improve the value of use

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

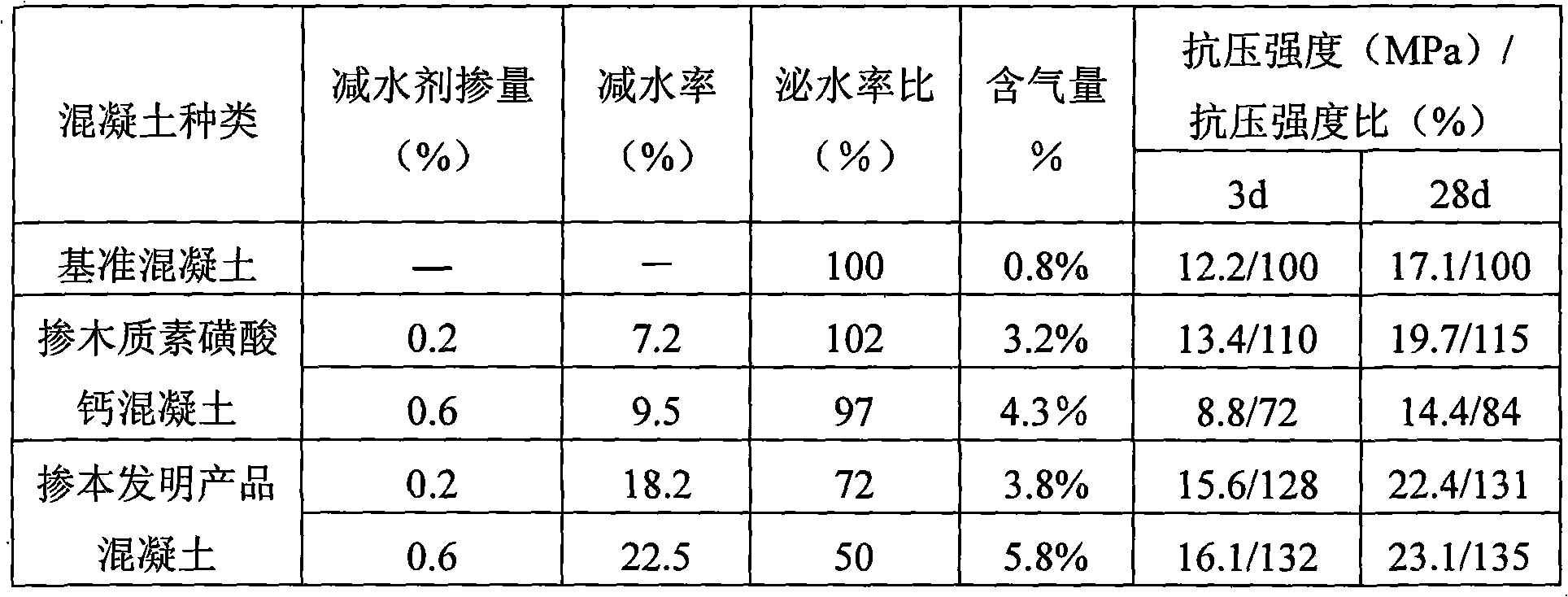

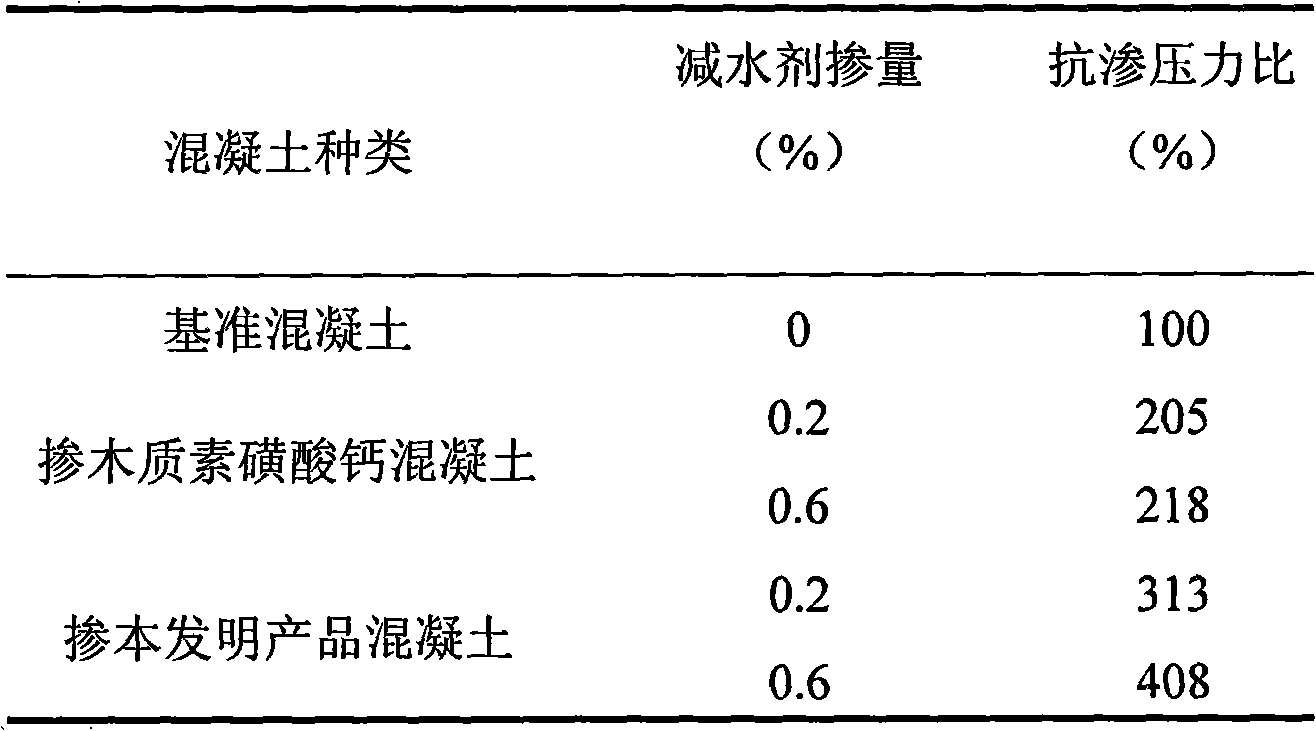

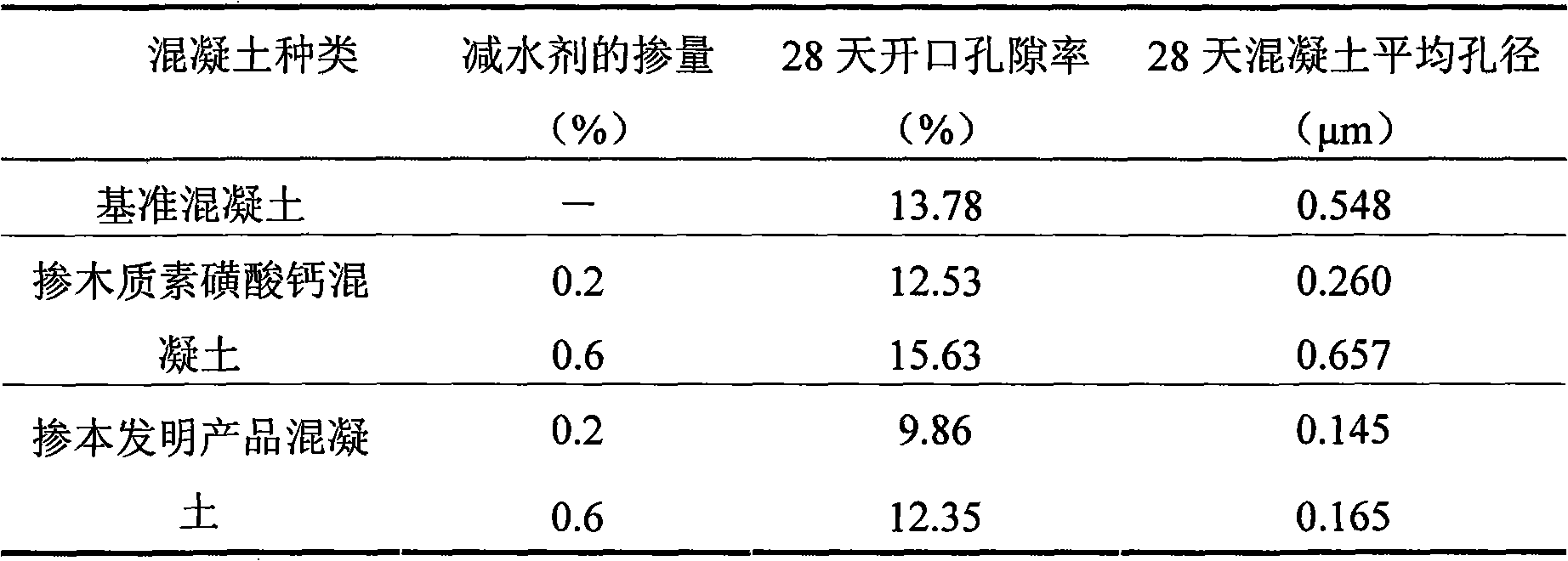

Examples

Embodiment 1

[0041]Dissolve 100 grams of wheatgrass lignin solid in 100 grams of water to prepare an aqueous solution with a concentration of 50% by weight, and heat it to 60°C while stirring; add 5 grams of hexamethylenediamine, drop 5g of formaldehyde, and react for 1 hour to obtain Amination of alkali lignin; add 50g of bisulfite to 15g of formaldehyde, heat to 50°C while stirring, and react for 20 minutes to obtain alkyl sulfonate compounds; aminate the above obtained aminated alkali lignin and alkyl sulfonate The acid salt compounds were mixed, and the pH value was adjusted to 11 with a NaOH aqueous solution with a concentration of 50% by weight, and the temperature was raised to 85° C., and the polycondensation reaction was carried out for 3 hours, and 2 grams of sodium cetyl sulfate was added to the above reaction product, and stirred for 20 Minutes, after cooling, the liquid product of the air-entraining water reducer of the present invention is obtained, and the powder product of t...

Embodiment 2

[0043] The bamboo pulp alkali lignin solid of 100 grams is dissolved in the water of 122 grams and is mixed with the aqueous solution that weight percent concentration is 45%, is heated to 80 ℃ while stirring; Add 10 grams of trihydroxyethylamine, dropwise 20g acetaldehyde, React for 3 hours to obtain aminated alkali lignin; add 100g of sodium p-aminobenzenesulfonate to 30g of acetaldehyde, heat to 70°C while stirring, and react for 60 minutes to obtain alkylsulfonate compounds; Mix aminated alkali lignin and alkyl sulfonate compounds, adjust the pH value to 13 with NaOH aqueous solution with a concentration of 50% by weight, heat up to 100°C, and perform polycondensation reaction for 4 hours, and add 3 The mixture of 1 gram of coconut oil alkyl alcohol amide and 3 gram of nonylphenol polyoxyethylene ether was stirred for 20 minutes, and the liquid product of air-entraining water reducer of the present invention was obtained after cooling, and the powdery product of the present...

Embodiment 3

[0045] Get 100 grams of wood pulp alkali lignin solid and dissolve it in 100 grams of water to prepare an aqueous solution with a concentration of 50% by weight, and heat it to 70°C while stirring; add 15 grams of dimethylamine, and drop 10g of glyoxal to carry out Amination reaction for 2 hours to obtain aminated alkali lignin products; take 80g of potassium sulfite, add 20g of glyoxal, heat to 60°C while stirring, and react for 50 minutes to obtain alkylsulfonate compounds; Mix the aminated alkali lignin and alkyl sulfonate compounds, while stirring, add an appropriate amount of NaOH solution with a concentration of 50% by weight to adjust the pH value to 12, heat up to 90 ° C, and carry out polycondensation reaction for 3 hours. The above reaction Add the mixture of 1 gram of sodium cetyl sulfate, 1 gram of coconut oil alkanolamide and 1 gram of nonylphenol polyoxyethylene ether in the product, stir for 20 minutes, and obtain the liquid product of the air-entraining water re...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com