Porous devitrified glass and manufacturing method thereof

A technology of porous glass-ceramic and its manufacturing method, which is applied in the field of glass-ceramic filter materials, can solve the problems of low compressive and flexural strength, low crystallization rate, etc., and achieve the effects of reducing tax, saving land, and reducing environmental pollution

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

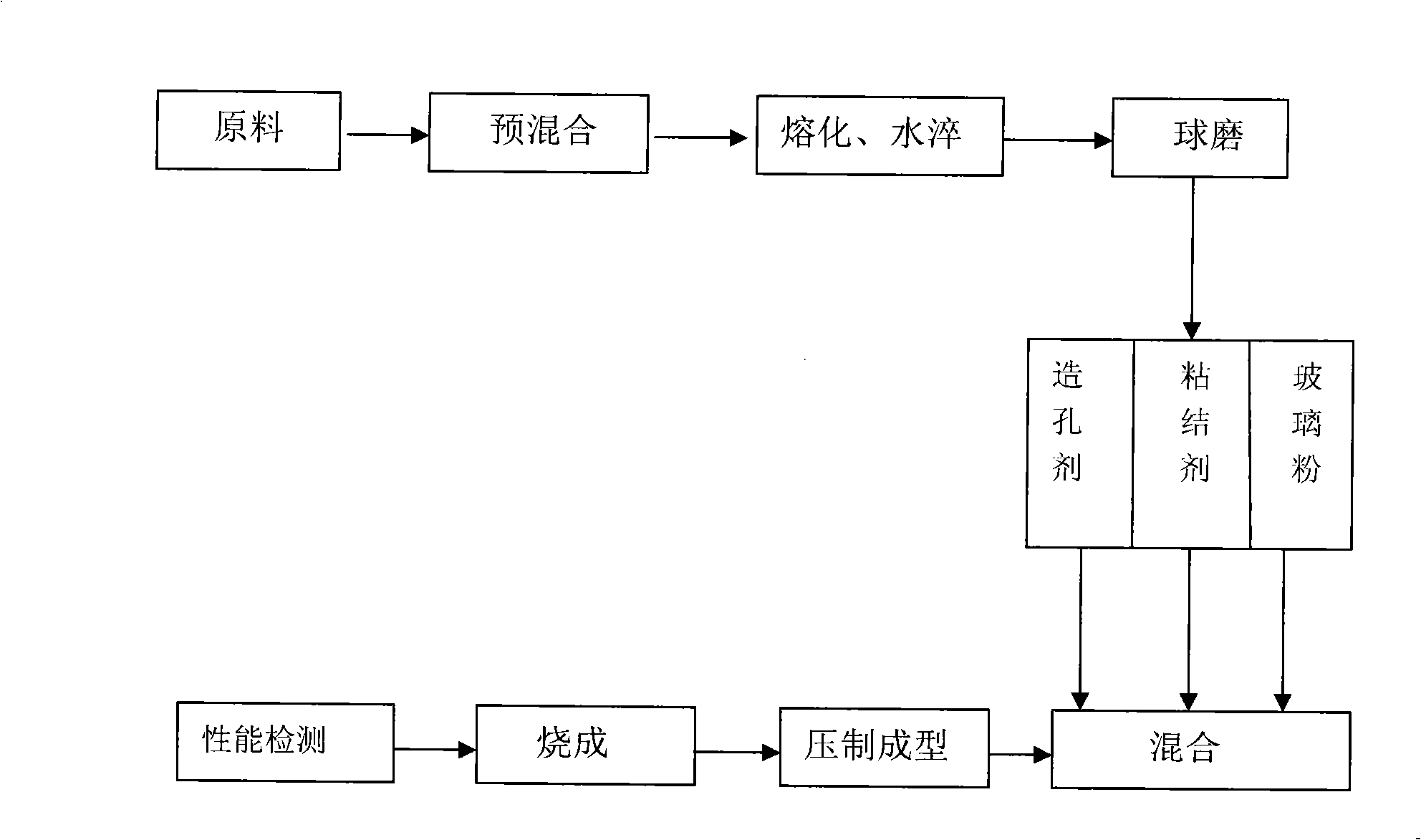

Method used

Image

Examples

Embodiment 1

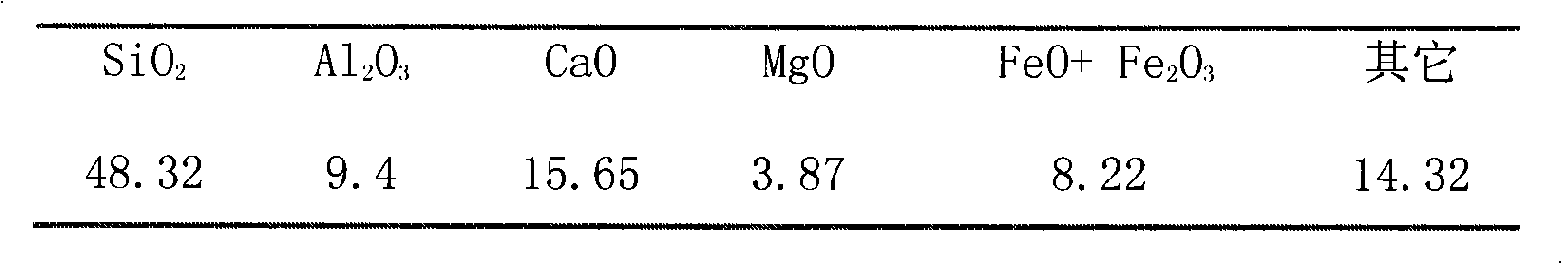

[0031] Formula: The fly ash used is taken from the No. 1 thermal power plant in the suburbs of Baotou City, and the rare earth tailings powder is taken from Baotou Iron and Steel Rare Earth Plant. The chemical composition is shown in Table 1 and Table 2, and the particle size is 200 mesh. The chemical composition (wt%) of the base glass is:

[0032]

[0033] 2. Batching and mixing: according to mass percentage: 20% fly ash, 27% rare tailings powder, 30% quartz sand, 16% dolomite, 7% spodumene for batching. Mix with a disc mixer, and the mixing time is 3-5min.

[0034] 3. Melting and water quenching: Put the uniformly mixed raw materials into a crucible furnace to melt, the melting temperature is 1450°C, and the melting time is 2.5 hours. The melted glass liquid is quickly poured into cold water to obtain water quenched glass Granules, dried and stored for later use.

[0035] 4. Preparation and molding of glass powder: Grind the dried glass particles on a ball mill so that...

Embodiment 2

[0039] 1. Material selection: The fly ash used is taken from the No. 2 thermal power plant in the suburbs of Baotou City, and the rare earth tailings powder is taken from Baotou Iron and Steel Rare Earth Plant. The chemical composition is shown in Table 2 and Table 3, and the particle size is 200 mesh. The chemical composition (wt%) of the base glass is:

[0040]

[0041]2. Batching and mixing: according to mass percentage: 17% fly ash, 35% rare tailings powder, 25% quartz sand, 19% dolomite, 4% spodumene for batching. Mix with a disc mixer, and the mixing time is 3-5min.

[0042] 3. Melting and water quenching: Put the uniformly mixed raw materials into a crucible furnace to melt, the melting temperature is 1450°C, and the melting time is 2.5 hours, then pour the melted glass into cold water quickly to obtain water quenched glass. Glass granules, dry them and save them for later use.

[0043] 4. Preparation and molding of glass powder: Grind dry glass particles on a ball...

Embodiment 3

[0047] 1. Material selection: The fly ash used was taken from the No. 1 Thermal Power Plant in the suburbs of Baotou, and the rare-earth tailings powder was taken from Baotou Iron and Steel Rare Earth Plant. The chemical composition is shown in Table 1 and Table 3, and the particle size is 200 mesh. The chemical composition (wt%) of the base glass is:

[0048]

[0049] 2. Ingredients: According to the mass percentage: 30% fly ash, 28% rare tailings powder, 21% quartz sand, 18% dolomite, 3% spodumene for ingredients. Mix with a disc mixer, and the mixing time is 3-5min.

[0050] 3. Melting and water quenching: Put the uniformly mixed raw materials into a crucible furnace to melt, the melting temperature is 1460°C, and the melting time is 3 hours, then pour the melted glass into cold water quickly to obtain water-quenched glass Granules, dried and stored for future use.

[0051] 4. Preparation and molding of glass powder: Grind the dried glass particles on a ball mill so th...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Compressive strength | aaaaa | aaaaa |

| Aperture | aaaaa | aaaaa |

| Compressive strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com