Lead free and cadmium free diamagnetic magnetic rotation glass

A magneto-optical and diamagnetic technology, which is applied in the field of lead-free and cadmium-free diamagnetic magneto-optical glasses for Faraday rotators, can solve the problems of low Verdet constant and oxidation Lead and other problems, to achieve excellent chemical stability and thermal stability, good wire drawing performance, high strength effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0030] Each oxide composition (mol%): SiO 2 3%, B 2 o 3 57%, La 2 o 3 10%, Yb 2 o 3 6%, Sm 2 o 3 2%, Bi 2 o 3 8%, Nb 2 o 5 5%, Ta 2 o 5 2%, Sb 2 o 3 1%, WO 3 6%.

[0031] The preparation method of this example: accurately weigh the raw materials of the above-mentioned oxides, mix them evenly, and use a platinum crucible or a high-quality zirconium-titanium corundum crucible to melt them in a clean vacuum high-temperature electric furnace or a high-frequency vacuum furnace at a temperature of 1050 ° C. After pouring and annealing the uniformly melted glass, it is made into lead-free and cadmium-free antimagnetic magnetic optical glass for various rotating components.

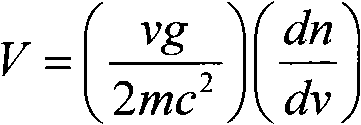

[0032] The Verdet constant V=+0.242min / oe.cm, Tg=660°C, Ts=680°C, crystallization temperature range of 690-880°C, and silk-forming performance at 950-1050°C of the diamagnetic magneto-optical glass of this embodiment good.

Embodiment 2

[0034] Oxide composition (mol%): SiO 2 2.0%, B 2 o 3 58%, La 2 o 3 6%, Yb 2 o 3 3%, Sm 2 o 3 3%, Bi 2 o 3 6%, Sb 2 o 3 5%, Ta 2 o 5 4%, WO 3 9%, ZnO 2%, BaO 2%.

[0035] The preparation method of this example: accurately weigh the raw materials of the above-mentioned oxides, mix them evenly, and melt them in a clean vacuum high-temperature electric furnace or a high-frequency vacuum furnace at a temperature of 1300 °C with a platinum crucible or a high-quality zirconium-titanium corundum crucible After pouring and annealing the uniformly melted glass, it is made into lead-free and cadmium-free antimagnetic magnetic optical glass for various rotating components.

[0036] The Verdet constant V of the diamagnetic magneto-optical glass in this embodiment is V=+0.162 min / oe.cm, and the glass has good silky properties.

Embodiment 3

[0038] Oxide composition (mol%): SiO 2 4%, B 2 o 3 55%, La 2 o 3 8%, Yb 2 o 3 9%, Sm 2 o 3 6%, Bi 2 o 3 13%, WO 3 5%.

[0039] The preparation method of this example: accurately weigh the raw materials of the above-mentioned oxides, mix the raw materials, and use a platinum crucible or a high-quality zirconium-titanium corundum crucible to melt in a clean vacuum high-temperature electric furnace or a high-frequency vacuum furnace at a temperature of 1150 ° C. After pouring and annealing the uniformly melted molten glass, it is made into lead-free and cadmium-free antimagnetic magnetic optical glass for various rotating components.

[0040] The Verdet constant V of the diamagnetic magneto-optical glass of this embodiment=+0.40min / oe.cm.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Field constant | aaaaa | aaaaa |

| Tg | aaaaa | aaaaa |

| Crystallization temperature | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com