Method and apparatus for manufacturing bamboo fiber

A manufacturing method and a manufacturing device technology, which are applied in the field of bamboo fiber manufacturing and its manufacturing device, can solve the problems of uneven fiber length, uneven fiber thickness, and inability to obtain fibers, and achieve excellent strength, good interweaving, and energy-saving batch size. production effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

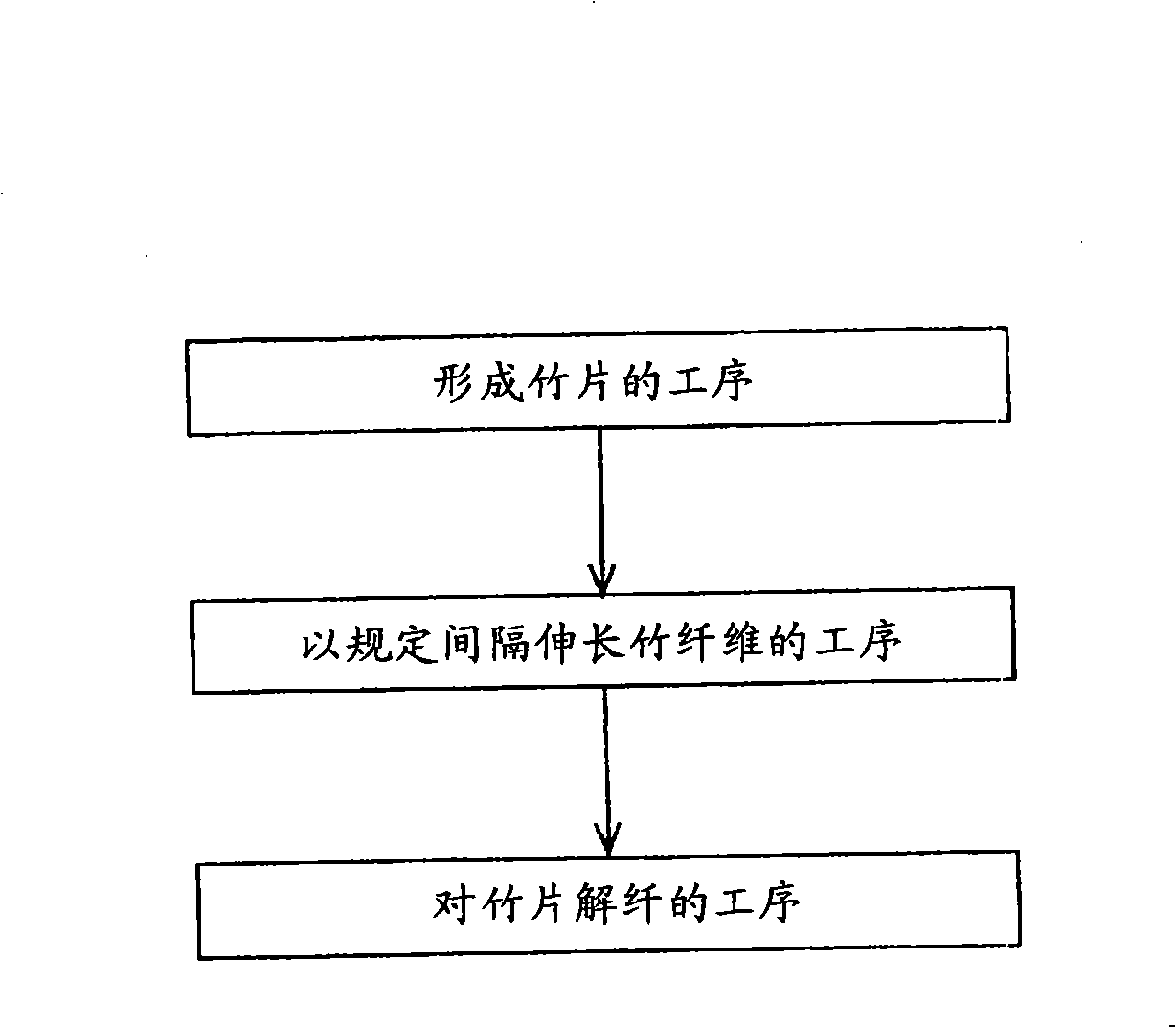

[0055] refer to Figure 1 ~ Figure 4 , illustrate the bamboo fiber manufacturing method of the present invention.

[0056] Such as figure 1 As shown in the process diagram, the first embodiment of the bamboo fiber manufacturing method of the present invention mainly includes: the process of forming bamboo chips, the process of elongating the bamboo fibers in the bamboo chips at predetermined intervals, and the process of defibrating bamboo chips.

[0057] First, the process of forming bamboo chips will be described.

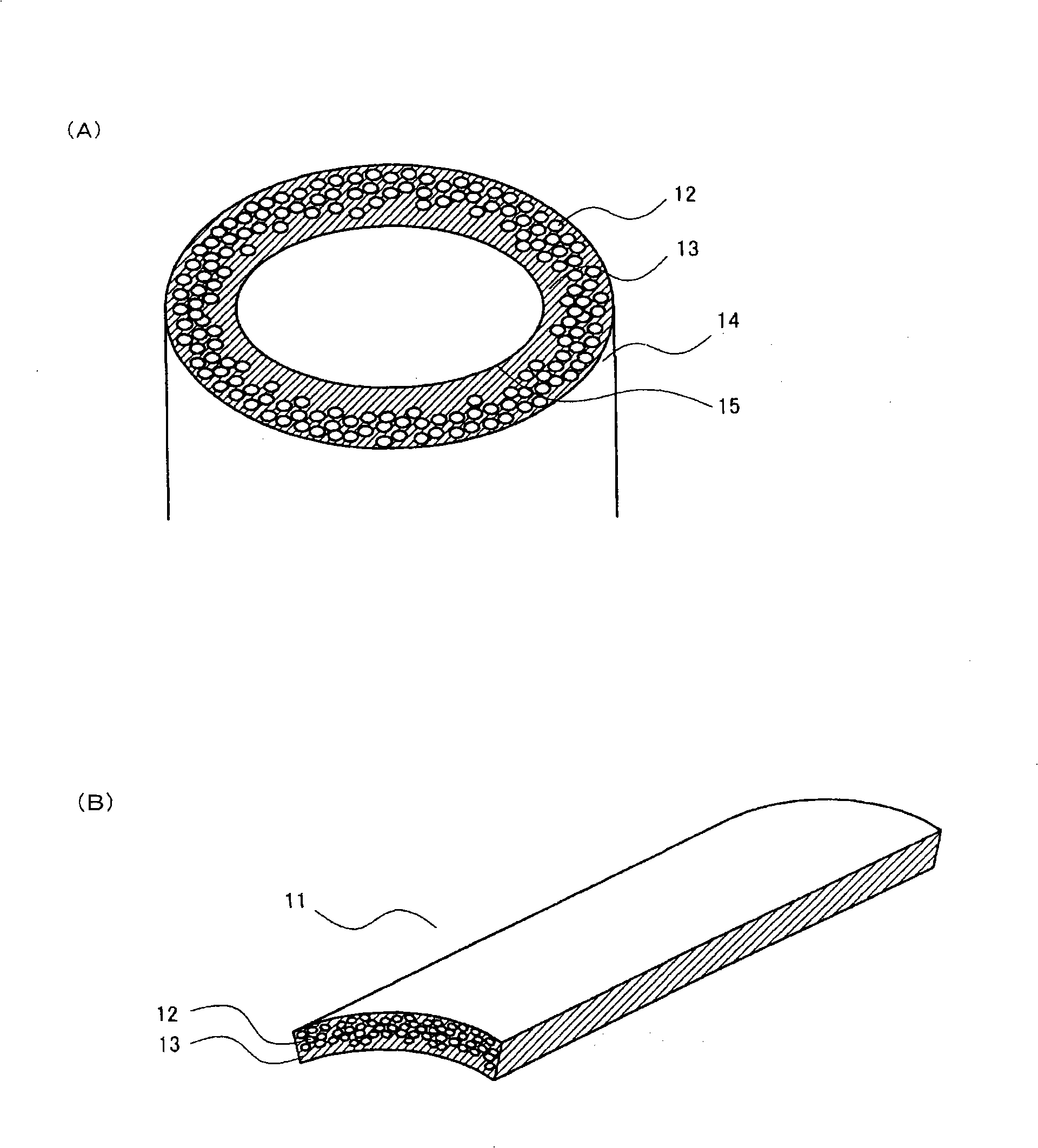

[0058] Such as figure 2 As shown in (A), the cross-section of the bamboo is circular and the interior is a hollow structure. Also, tubes 12 such as pipes for transporting water and inorganic substances from underground stems, and screen pipes (pipes) for transporting nutrients obtained through photosynthesis are scattered irregularly. This tube 12 is used as bamboo fiber. Bamboo meat 13 is filled between these tubes 12 . The tubes 12 are densely present on...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com