High-temperature flue gas thermal electron emission type particulate matter charge device

A technology of high-temperature flue gas and charging device, applied in the direction of particle charging/ionization, electrostatic separation, etc., can solve the problems of affecting the charging effect of dust, uneven distribution of electron density in the charging area, and easy poisoning of emitters, etc., to achieve The effect of overcoming electrical insulation problems, improving high temperature resistance, and improving uniformity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

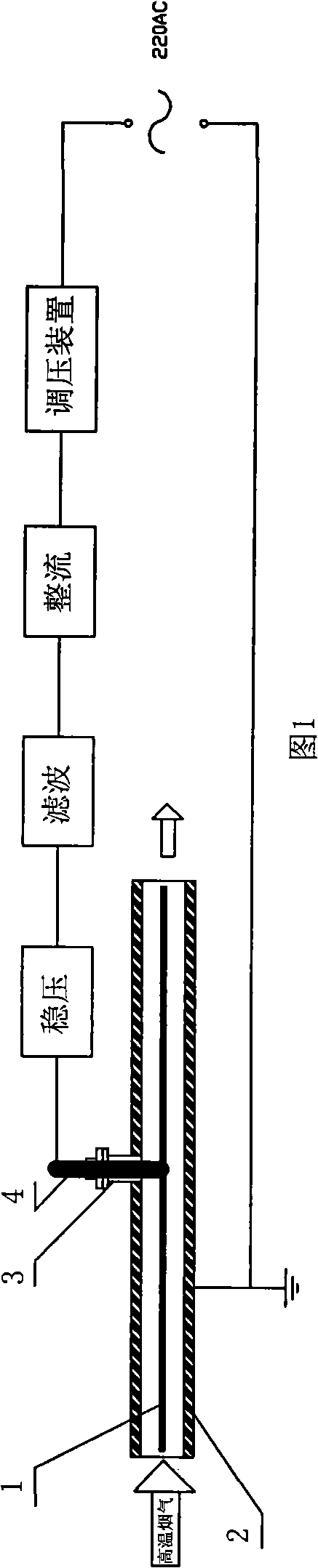

[0010] Embodiment 1: As shown in FIG. 1 , a high-temperature flue gas thermionic emission charging device for particulate matter is composed of an emitting electrode rod 1 and a conductive cylinder 2 . In order to give full play to the characteristics of thermal electron emission, the device of the present invention adopts a tubular structure. The emitter electrode rod is made of rare earth tungsten composite functional material as the thermal electron emission cathode; the outer wall of the conductive cylinder is grounded as the thermal electron emission anode; the middle part of the conductive cylinder is provided with an insulating sleeve 3, and a stainless steel conductive suspender 4 is used to pass through the insulating sleeve The tube suspends the emitter electrode rod in the center of the conductive cylinder to ensure that the thermal electrons are evenly emitted to the surroundings. When installed and used, the two emitters are connected with the cathode of the power...

Embodiment 2

[0012] Embodiment 2: Basically the same as Embodiment 1, the difference is: the rare earth tungsten composite functional material contains rare earth oxide CeO in its components 2 and La 2 o 3 , the mass percentage of the rare earth oxide is 1%, and the balance is tungsten; the ratio between the two rare earth oxides can be arbitrary.

Embodiment 3

[0013] Embodiment 3: Basically the same as Embodiment 2, the difference is: the rare earth tungsten composite functional material contains rare earth oxide CeO in its components 2 , La 2 o 3 and Y 2 o 3 , the mass percentage of the rare earth oxide is 2.2%, and the balance is tungsten; the ratio of the rare earth oxides can be arbitrary.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com