Grain boundary phase-reconstructed high-corrosion resistance Sintered NdFeB magnet and preparation method thereof

A NdFeB, high corrosion resistance technology, applied in the direction of magnetic objects, inductance/transformer/magnet manufacturing, magnetic materials, etc., can solve the problems of increased process, short corrosion resistance time, hydrogen embrittlement, etc., to improve intrinsic resistance Corrosion resistance, high intrinsic corrosion resistance, simple process effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

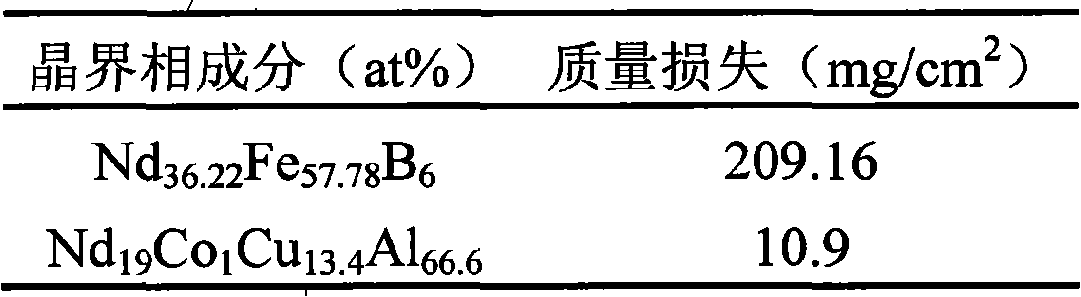

Embodiment 1

[0017] 1) Redesign of grain boundary phase alloy composition, the composition is Nd 19 co 1 Cu 13.4 Al 66.6 (at%);

[0018] 2) The main phase alloy and the reconstructed grain boundary phase alloy were prepared separately. The main phase alloy is made of NdFeB ingot alloy by casting process, and its composition is Nd 13.12 Fe 80.69 B 5.73 (Dy 0.22 Ga 0.24 )(at%), reconstructed grain boundary phase alloy Nd 19 co 1 Cu 13.4 Al 66.6 (at%) The quick quenching strip is made by the quick quenching process;

[0019] 3) Powder the main phase alloy and the reconstructed grain boundary phase alloy separately. The primary crushing is carried out by the jaw crusher, the secondary crushing is carried out by the secondary crusher, and then the powders with an average particle diameter of 4 μm and 2 μm are respectively made into powders by jet mills under the protection of nitrogen;

[0020] 4) Evenly mix the reconstituted grain boundary phase alloy powder with the main phase a...

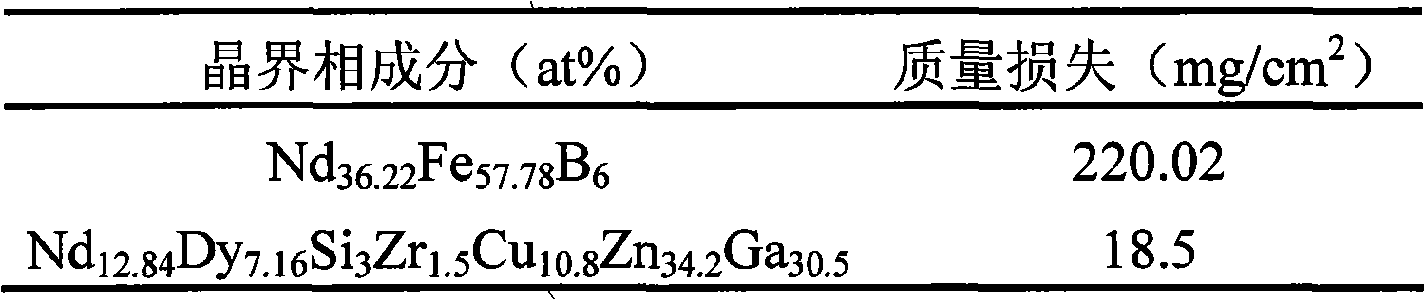

Embodiment 2

[0028] 1) Redesign of grain boundary phase alloy composition, the composition is Nd 12.84 Dy 7.16 Si 3 Zr 1.5 Cu 10.8 Zn 34.2 Ga 30.5 (at%);

[0029] 2) The main phase alloy and the reconstructed grain boundary phase alloy were prepared separately. The main phase alloy is made of NdFeB flakes by quick-setting stripping process, and its composition is Nd 12.2 Fe 80.15 B 5.9 (Tb 0.31 co 1.24 Nb 0.2 )(at%), reconstructed grain boundary phase alloy Nd 12.84 Dy 7.16 Si 3 Zr 1.5 Cu 10.8 Zn 34.2 Ga 30.5 (at%) Ingot alloy made by casting process;

[0030] 3) Powder the main phase alloy and the reconstructed grain boundary phase alloy separately. The primary crushing is carried out by the jaw crusher, the secondary crushing is carried out by the secondary crusher, and then the powders with an average particle diameter of 3.5 μm and 1 μm are respectively made by ball milling under the protection of petroleum ether;

[0031] 4) Evenly mix the reconstituted grain bounda...

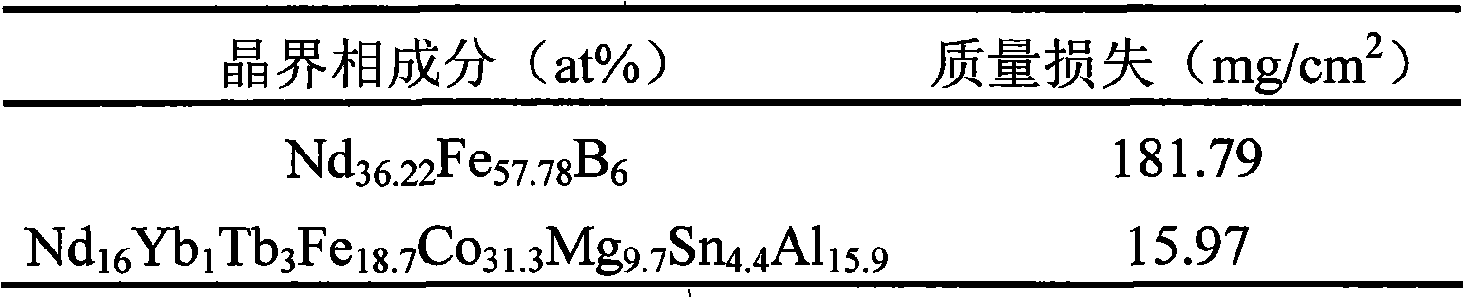

Embodiment 3

[0039] 1) Redesign of grain boundary phase alloy composition, the composition is Nd 16 Yb 1 Tb 3 Fe 18.7 co 31.3 Mg 9.7 sn 4.4 Al 15.9 (at%);

[0040] 2) The main phase alloy and the reconstructed grain boundary phase alloy were prepared separately. Both of them are made of NdFeB flakes by using the quick-setting stripping process, and their components are Nd 14.33 Fe 78.91 B 6 (Ga 0.36 Cu 0.2 Zr 0.2 )(at%) and Nd 16 Yb 1 Tb 3 Fe 18.7 co 31.3 Mg 9.7 sn 4.4 Al 15.9 (at%);

[0041] 3) Powder the main phase alloy and the reconstructed grain boundary phase alloy separately. Direct crushing by hydrogen explosion method, saturated hydrogen absorption at room temperature, and then dehydrogenation at 520°C for 8 hours to make hydrogen explosion powder, and finally make powders with average particle diameters of 4.3 μm and 2 μm respectively by jet mill under nitrogen protection;

[0042] 4) Evenly mix the reconstituted grain boundary phase alloy powder with the m...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com