Austenitic stainless steel accurate steel strip performance prediction model and cold rolling process planning thereof

A technology of austenitic stainless steel and deformation, applied in the field of steel strip manufacturing, can solve problems affecting the mechanical properties of products, difficulties in designing precision cold rolling processes, and difficulties in product quality assurance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0085] specific implementation plan

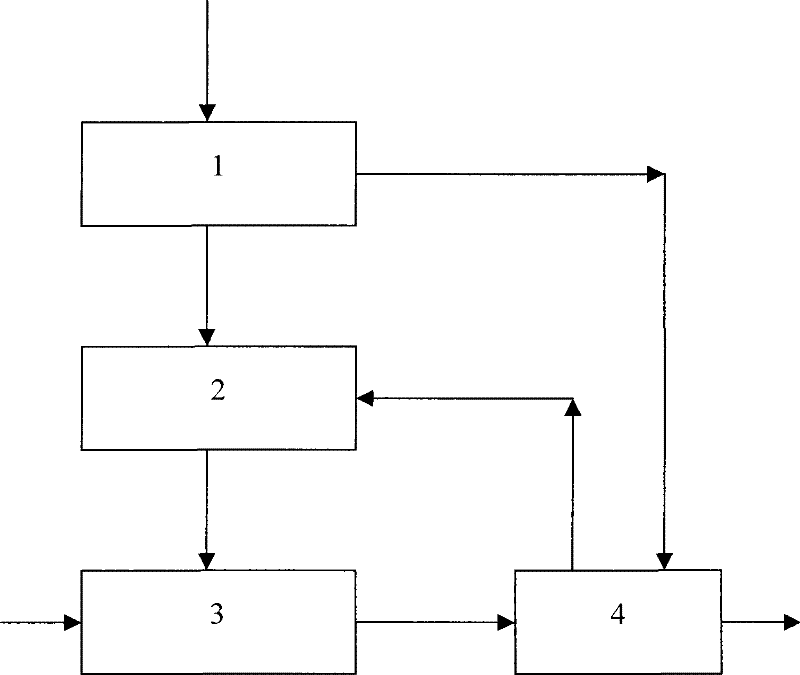

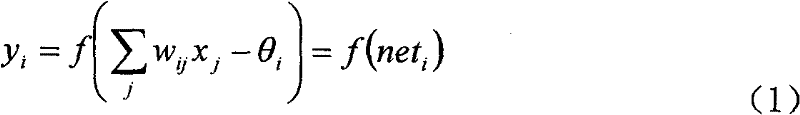

[0086] The present invention is realized in the following way: after the final rolling deformation prediction module 3 has been trained, it absorbs the knowledge contained in the previous production data and stores it in the "data storage memory bank 1". The "stainless steel cold-rolled steel plate performance prediction model" designed by the invention realizes the function of determining the final rolling deformation by taking various rolling process parameters and the mechanical properties of the final stainless steel strip as input. After the prediction model is put into use, the prediction model can be continuously trained to further improve the accuracy of the prediction model by continuously collecting subsequent production process and performance record data.

[0087] Apply the above-mentioned "a performance prediction model of austenitic stainless steel precision steel strip", implement the precision cold rolling process design me...

PUM

| Property | Measurement | Unit |

|---|---|---|

| tensile strength | aaaaa | aaaaa |

| yield strength | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com