Optical fiber cable section box board and its shaping method

A technology of optical cable transfer box and molding method, which is applied in the direction of chemical instruments and methods, lamination, layered products, etc., can solve the problems of large residual stress, box door deflection deformation, adverse effects, etc. Effects of long-term creep, improvement of specific strength and specific stiffness, and reduction of usage

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

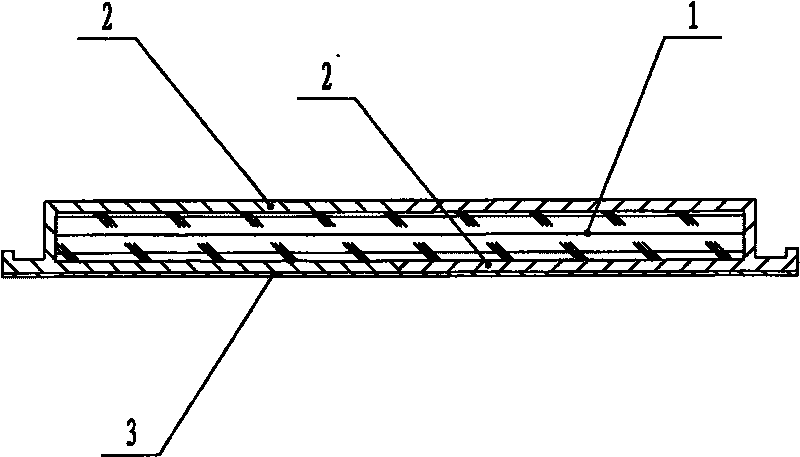

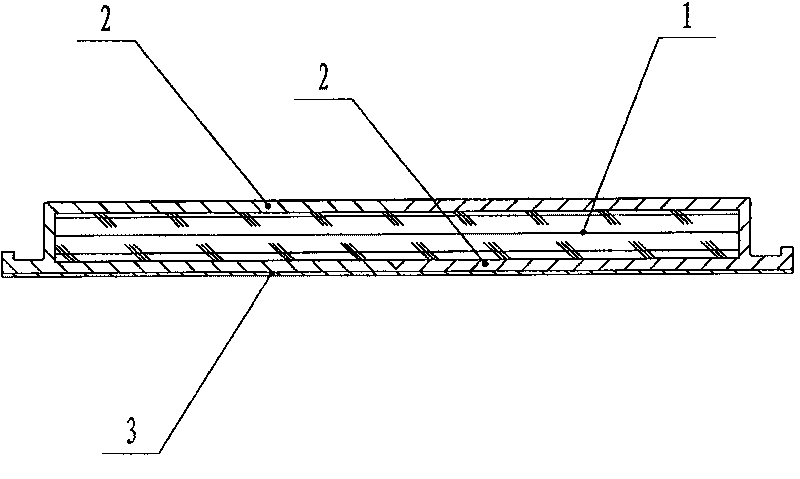

[0029]Firstly, the sheet molding compound with high fluidity is matured for later use; then the 10mm thick sawdust board is cut according to the prescribed pattern of the box board sandwich, and the sawdust board is heated and baked in a far-infrared soaking furnace at 140°C After dehydration, keep the temperature for standby; then heat the mold, and when the temperature of the mold rises to 150-160°C, spray a layer of 20-micron thick heat-cured powder layer 3 on the bottom model surface of the mold; heat-cured powder layer 3 is sprayed 10 seconds after the completion of the covering action, a layer of 2mm thick sheet molding compound is first laid on the top of the heat-curing powder layer 3 in order. The time interval for laying sheet molding compound on layer 3 is 10 seconds; then put the insulated sawdust board, and then spread a layer of 3mm thick sheet molding compound on the sawdust board; finally start the press to go down, Good sheet molding compound layer 2, wood-bas...

Embodiment 2

[0031] Firstly, the sheet molding compound with high fluidity is matured for later use; then the 8mm-thick particleboard is cut according to the prescribed pattern of the box-board sandwich, and the particleboard is heated and dried in a far-infrared soaking furnace at 130°C to remove moisture Afterwards, keep the temperature for standby; then heat the mold so that when the temperature of the mold rises to 130-140°C, spray a layer of 20-micron heat-cured powder layer 3 on the bottom model surface of the mold; the spraying action of the heat-cured powder layer 3 is completed After 10 seconds, a layer of 3mm thick sheet molding compound is first spread on the heat-cured powder layer 3 in order. The time interval for laying the sheet molding compound is 10 seconds; then place the insulated particle board, and then lay a layer of 3mm thick sheet molding compound on the particle board; The plastic layer 2, the wood-based panel layer 1 and the heat-cured powder layer 3 are pressuriz...

Embodiment 3

[0033] Firstly, the sheet molding compound with high fluidity is matured for later use; then the 5mm thick fiberboard is cut according to the prescribed pattern of the box-board sandwich, and the fiberboard is heated and dried in a far-infrared soaking furnace at 110°C to remove moisture After that, keep the temperature for standby; then heat the mold so that when the temperature of the mold rises to 120-130°C, spray a layer of 20-micron heat-cured powder layer 3 on the bottom model surface of the mold; the spraying action of the heat-cured powder layer 3 is completed After 10 seconds, a layer of 2mm thick sheet molding compound is first spread on the heat-cured powder layer 3 in order. The time interval for laying the sheet molding compound is 10 seconds; then place the fiberboard that has been insulated, and then lay a layer of 2mm thick sheet molding compound on the fiberboard; finally start the press to go down, and apply the laid sheet molding compound. The plastic layer ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com