Preparation of maleic acid di-methyl ester

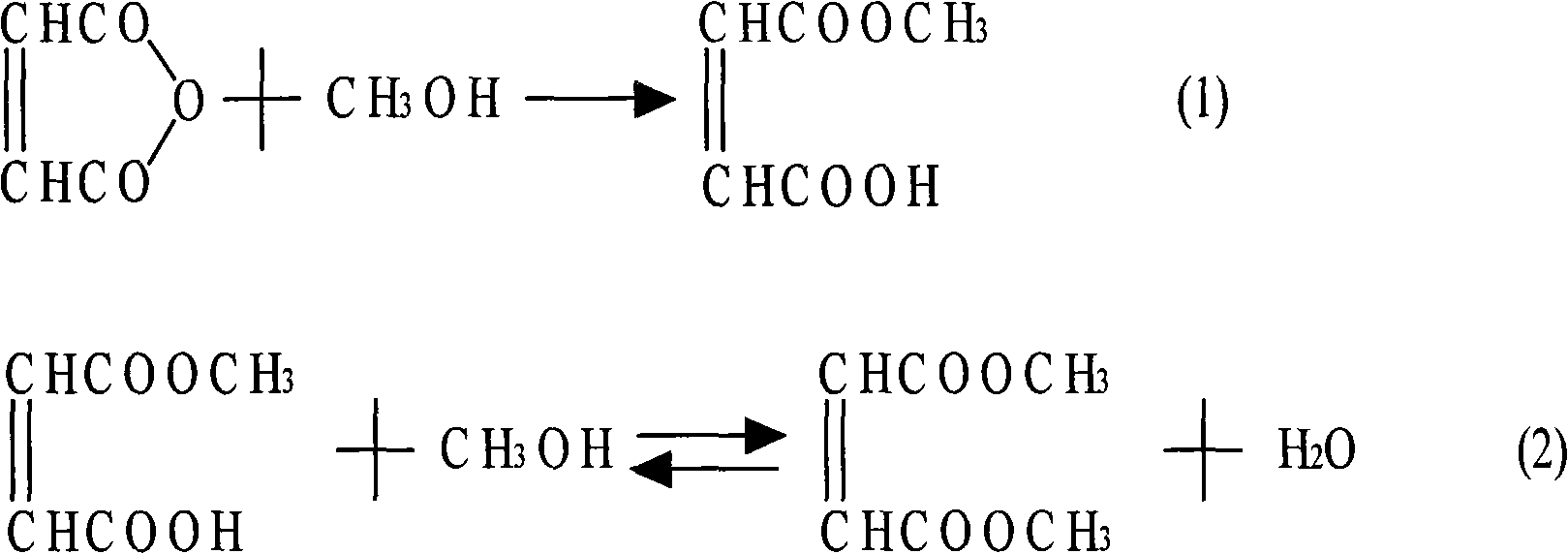

A technology of dimethyl maleate and monomethyl maleate, which is applied in the field of preparing dimethyl maleate by reacting maleic anhydride with methanol, can solve the problem that monoesterification and diesterification cannot be used at the same time, and the production process complex issues

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

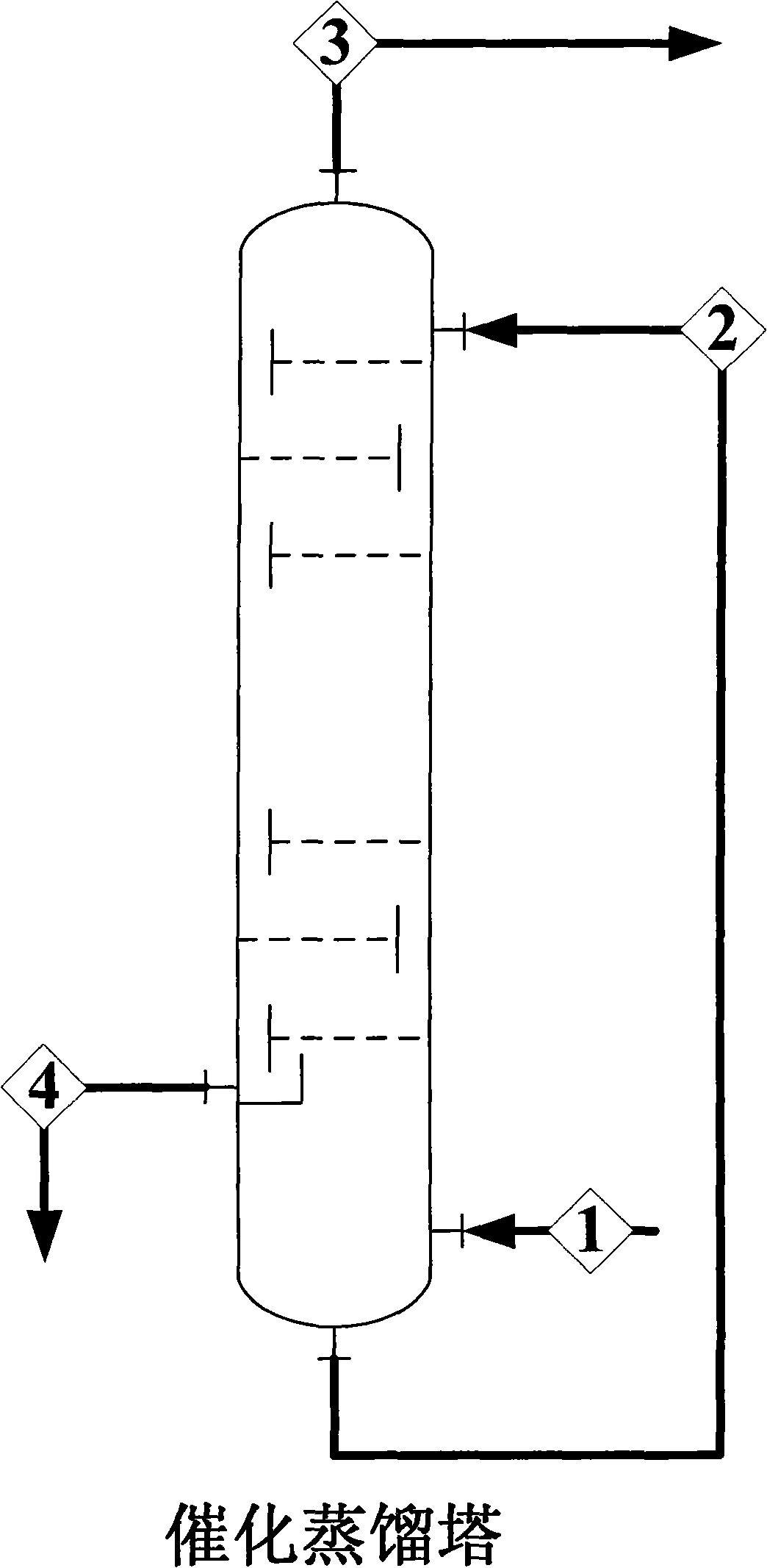

[0047] Continuously add the mixture of methyl alcohol and maleic anhydride in the tower still of catalytic distillation tower (15 trays, resin catalyst of tray packing, the trade mark is DNW-1), the mol ratio of methyl alcohol and maleic anhydride is 4: 1, Monoesterification reaction temperature 120 ℃ (overhead pressure is 1.3 bar, and tower pressure drop is 1.7 bar), and the heat of esterification reaction vaporizes excess methyl alcohol, wherein the mol ratio of the vapor methanol that produces and monomethyl maleate is 2.2: 1.

[0048] The liquid phase reaction product containing monomethyl maleate is added to the third plate, and the feeding flow is controlled so that the residence time of the monoesterification reaction and the double esterification reaction are 30 minutes and 2 hours respectively. At the bottom of the catalytic distillation tower 15 tray places obtain product, wherein dimethyl maleate content 97.6%, methanol content 1.4%, water content 1%; Obtain excess ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com