Mesopore titanic oxide /zinc oxide composite film preparation method

A technology of mesoporous titanium oxide and composite thin film, which is applied in the direction of electrical components, circuits, semiconductor devices, etc., can solve the problems of increased probability, increased dark current, increased transmission and residence time, etc., and achieves low cost, easy control, and preparation The effect of simple method

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

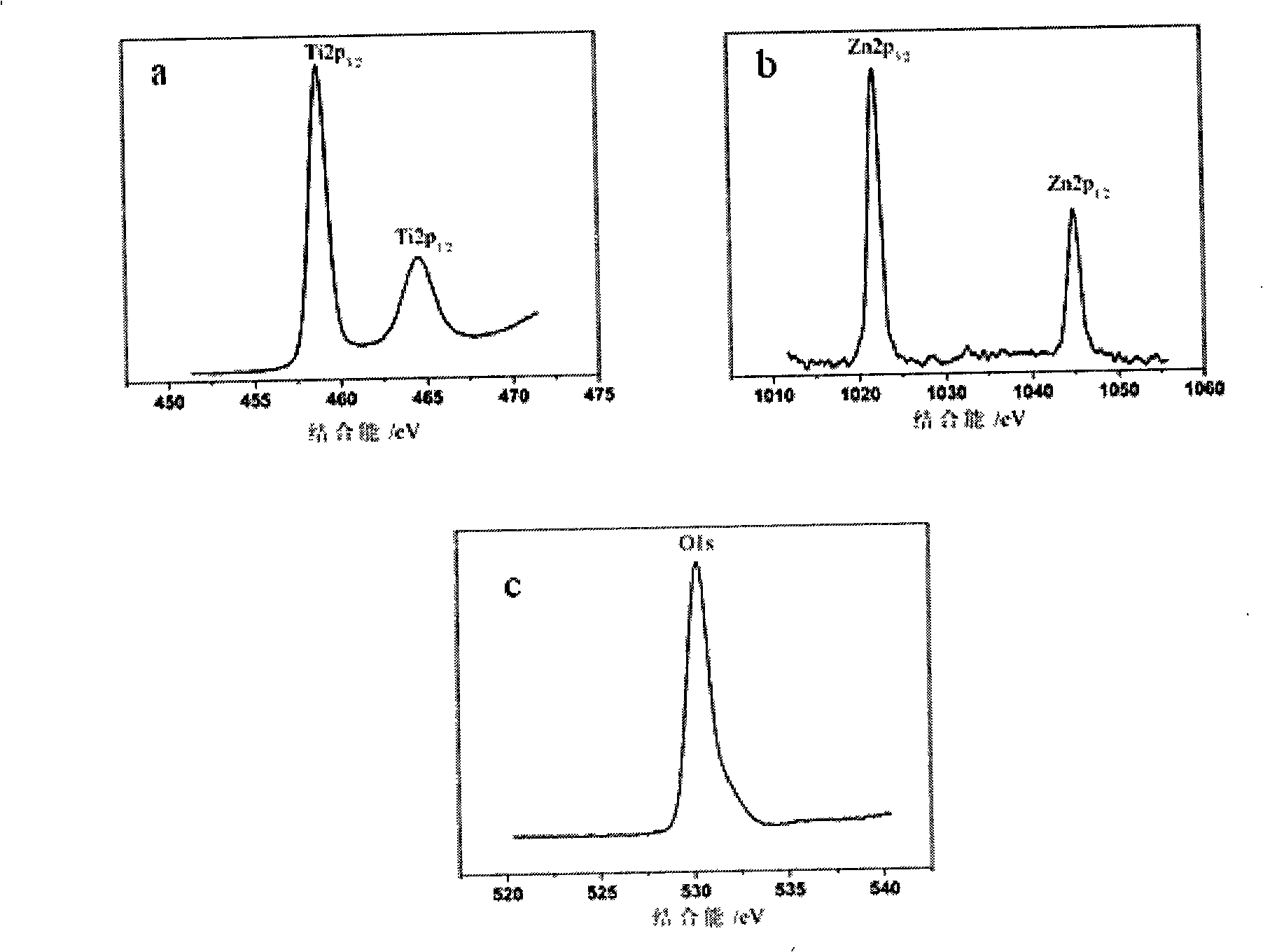

[0024] TiO 2 Preparation of / ZnO composite precursor solution: Dissolve 1.3g triblock polymer polyoxyethylene-polyoxypropylene-polyoxyethylene (P123) in absolute ethanol, add 3.2g concentrated hydrochloric acid after completely dissolving, and stir for 0.5 hours ; Then add 5ml of isopropyl titanate dropwise, stir for 0.5 hours, then add 0.2g of zinc acetate dihydrate dropwise, stir at room temperature for 3 hours, and let stand for 24 hours for use.

[0025] Clean the substrate: the substrate is a single crystal silicon wafer with a crystal orientation of 100. The substrate was ultrasonically cleaned in absolute ethanol for 15 minutes, then ultrasonically cleaned in acetone for 15 minutes, and then ultrasonically cleaned in absolute ethanol for 15 minutes, N 2 Blow dry and set aside.

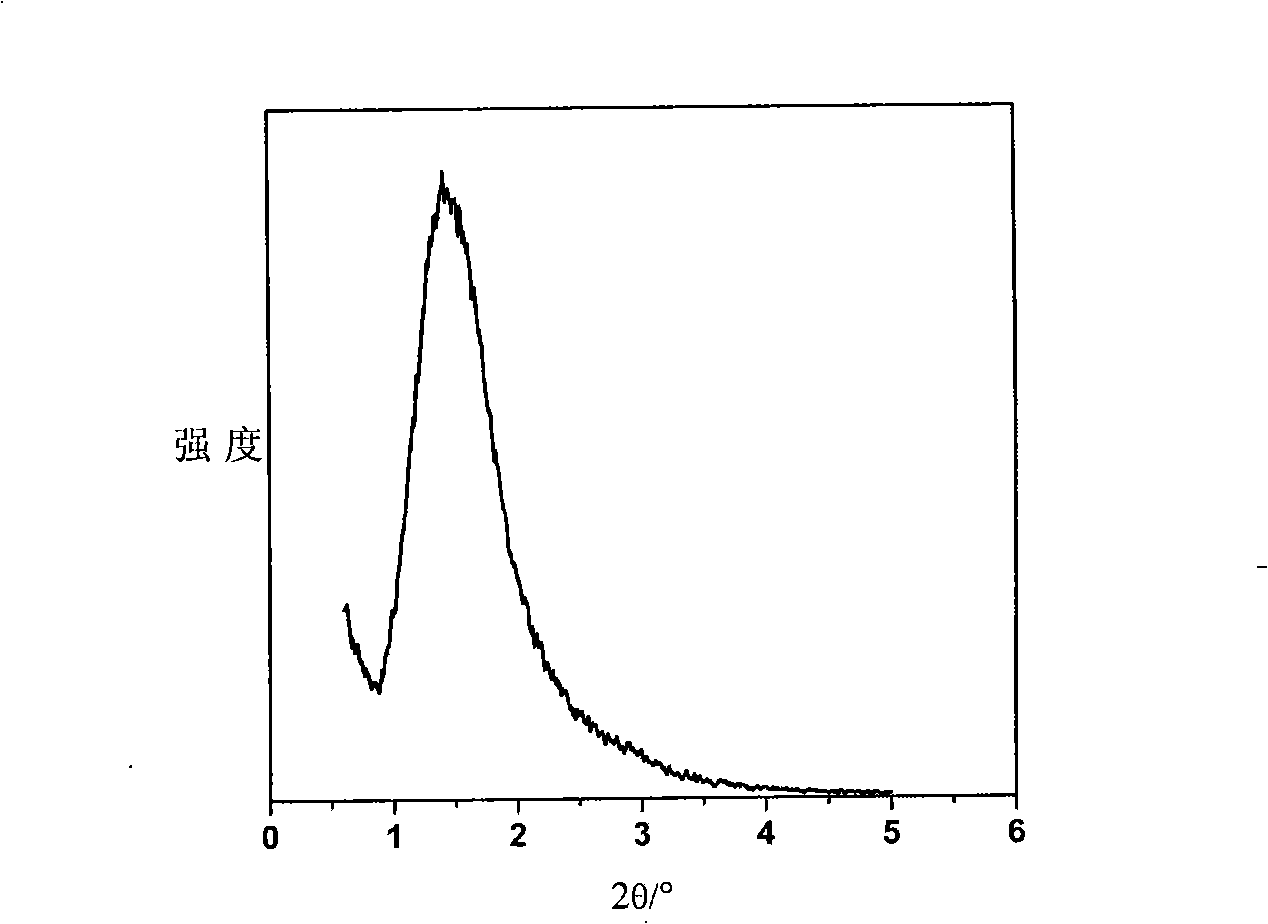

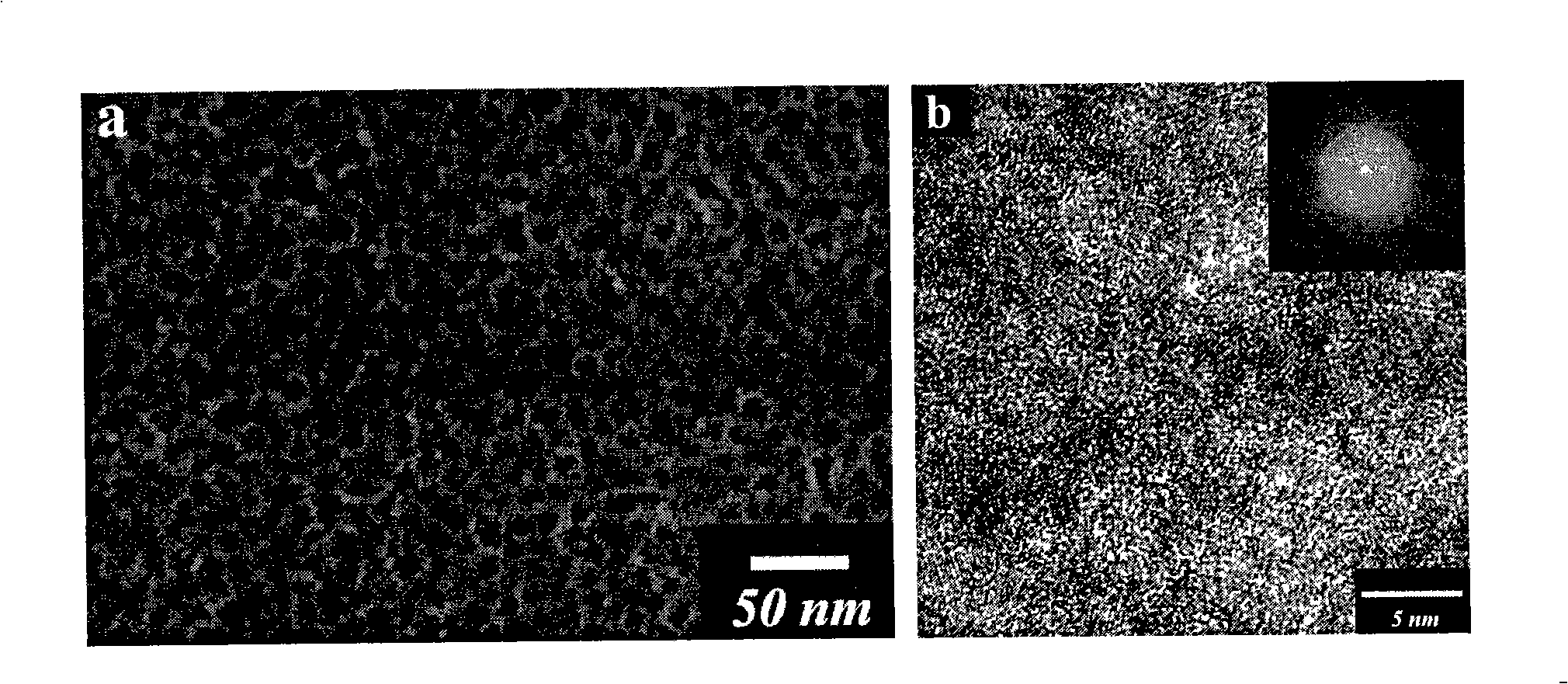

[0026] Spin coating of composite thin films: the prepared TiO 2 / ZnO composite precursor solution was dropped onto the rotating substrate, the rotation speed was 2000 rpm, and the spin coatin...

Embodiment 2

[0030] TiO 2 Preparation of / ZnO composite precursor solution: Dissolve 1.3g triblock polymer polyoxyethylene-polyoxypropylene-polyoxyethylene (P123) in absolute ethanol, add 3.2g concentrated hydrochloric acid after completely dissolving, and stir for 0.5 hours ; Then add 6.2ml of tetra-n-butyl titanate dropwise, stir for 0.5 hours, then add 0.44g of zinc acetate dihydrate dropwise, stir at room temperature for 3 hours, and let stand for 24 hours for use.

[0031] Clean the substrate: the substrate is a single crystal silicon wafer with a crystal orientation of 100. The substrate was ultrasonically cleaned in absolute ethanol for 15 minutes, then ultrasonically cleaned in acetone for 15 minutes, and then ultrasonically cleaned in absolute ethanol for 15 minutes, N 2 Blow dry and set aside.

[0032] Spin coating of composite thin films: the prepared TiO 2 / ZnO composite precursor solution was dropped onto the rotating substrate, the rotation speed was 2000 rpm, and the spin...

PUM

| Property | Measurement | Unit |

|---|---|---|

| pore size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com