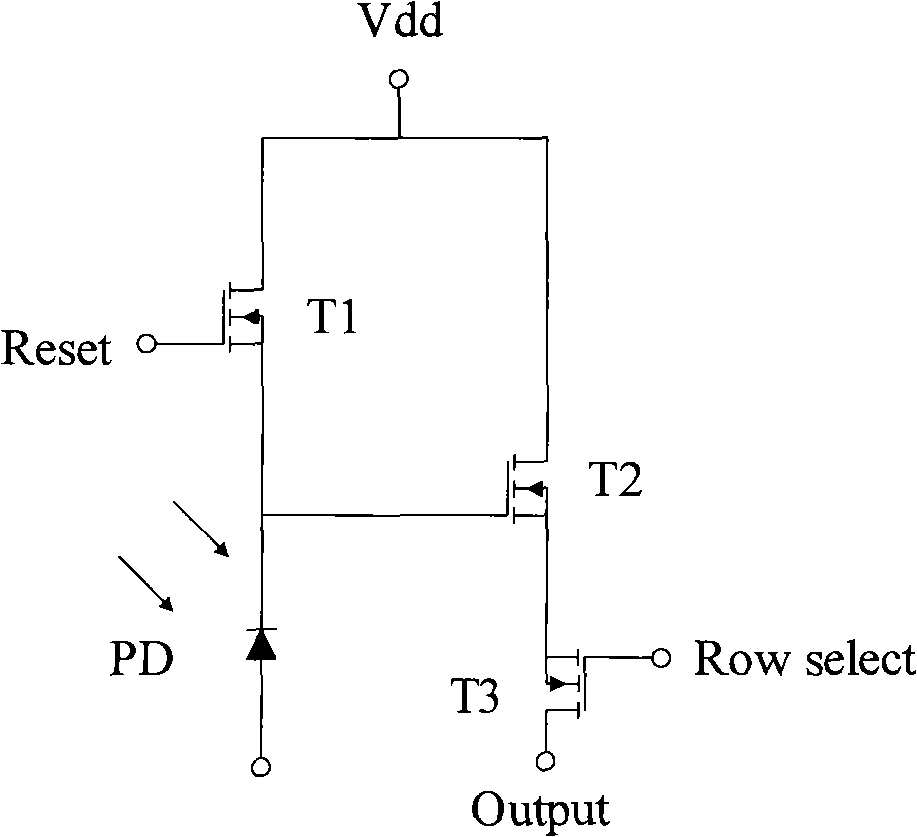

CMOS image sensor and method for forming same

An image sensor and pixel unit technology, applied in the manufacture of electric solid-state devices, semiconductor devices, semiconductor/solid-state devices, etc., can solve problems such as difficult wiring, channel length cannot be reduced, and pixel unit difficulties

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

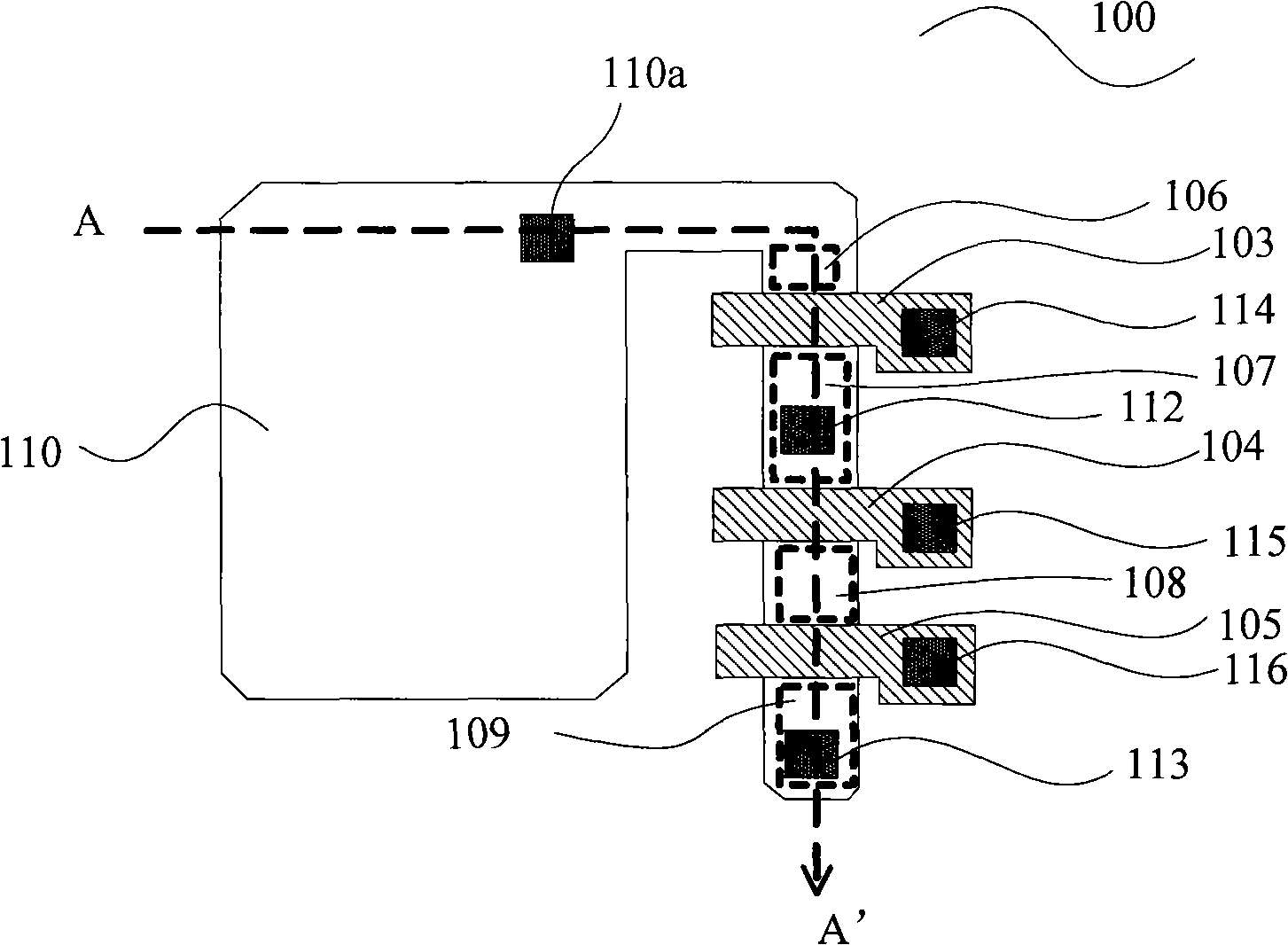

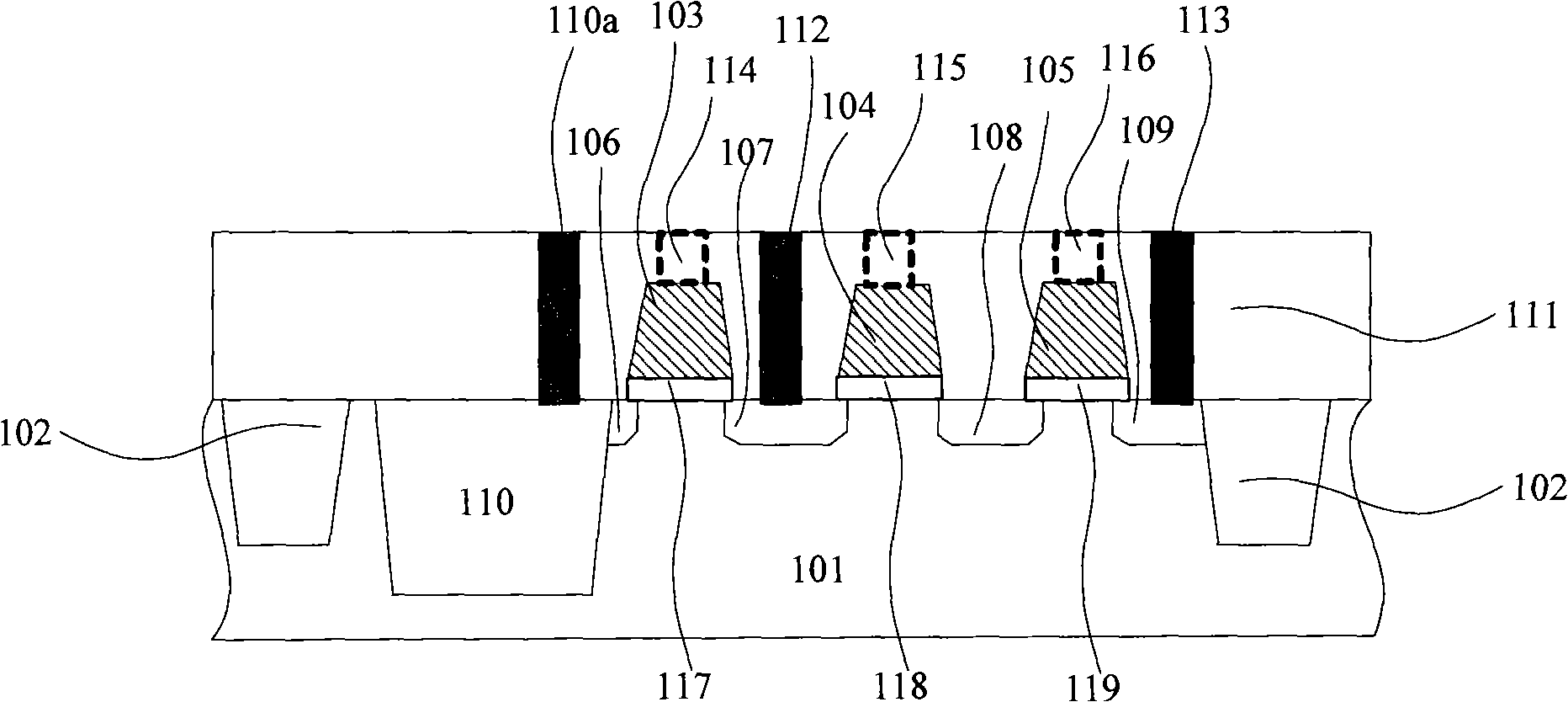

[0055] The present invention shares an output contact hole by connecting the column of the CMOS image sensor to the drains of the output transistors of the first pixel unit and the second pixel unit of the adjacent pixel unit pair; or by connecting the pixel unit pair of the CMOS image sensor The drains of the output transistors of the first pixel unit and the second pixel unit are connected to share an output contact hole, and at the same time, the drains of the reset transistors of the first pixel unit are connected to the second pixel of the adjacent CMOS image sensor pixel unit column. The drain of the reset transistor of the unit is connected to share a power contact hole, and the drain of the reset transistor of the second pixel unit is connected to the drain of the reset transistor of the first pixel unit of another adjacent CMOS image sensor pixel unit pair in the column direction. Connect and share a power contact hole. Under the condition of not lowering the technolo...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com