Steel rapid-heating device and steel rapid-heating method

A rapid heating and steel technology, applied in the direction of induction heating, process efficiency improvement, energy efficiency improvement, etc., can solve the problems of uneven heating, high energy consumption, large heat radiation of flame heating technology, and achieve wide heating temperature range, High temperature control accuracy, no environmental pollution effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

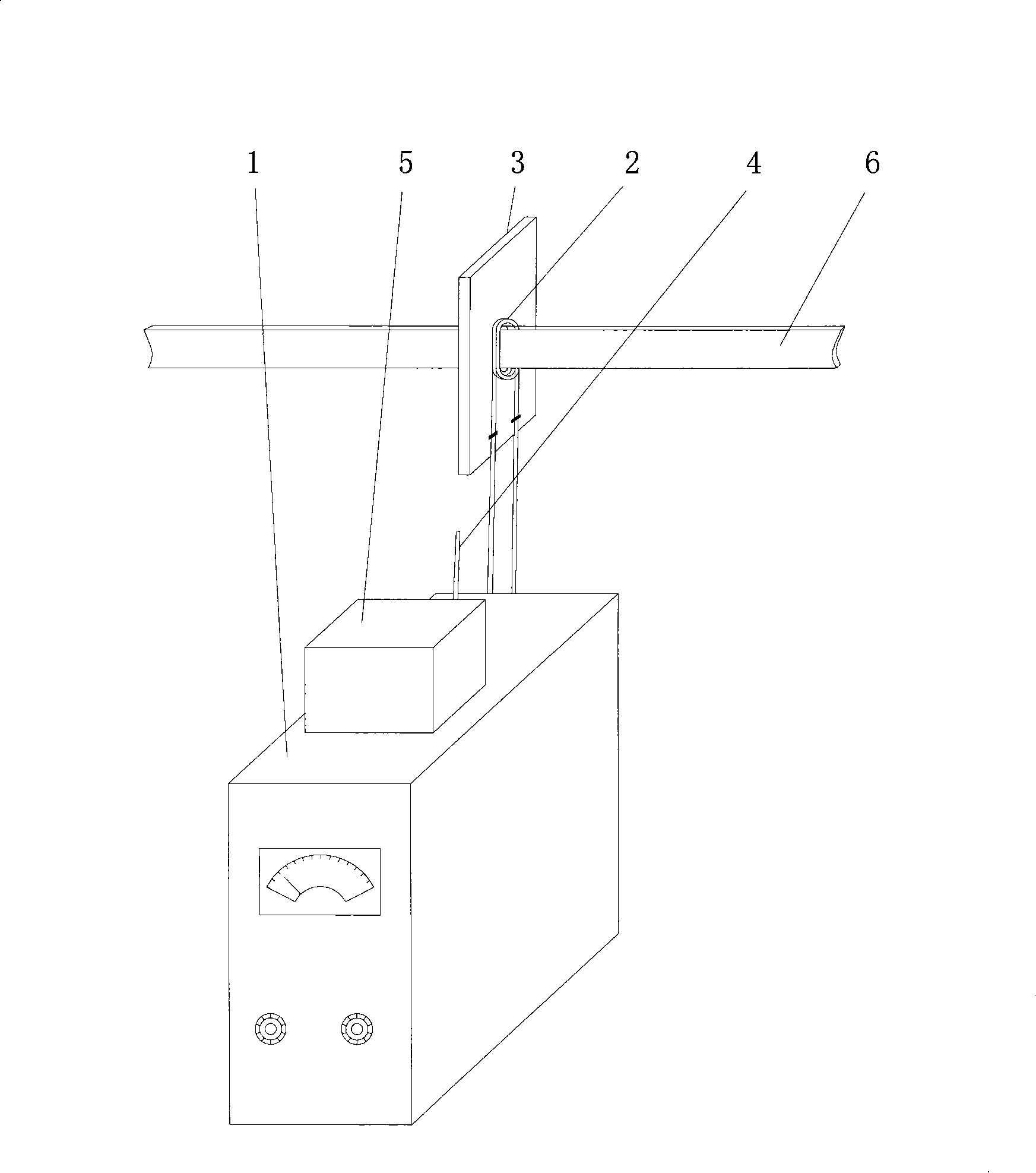

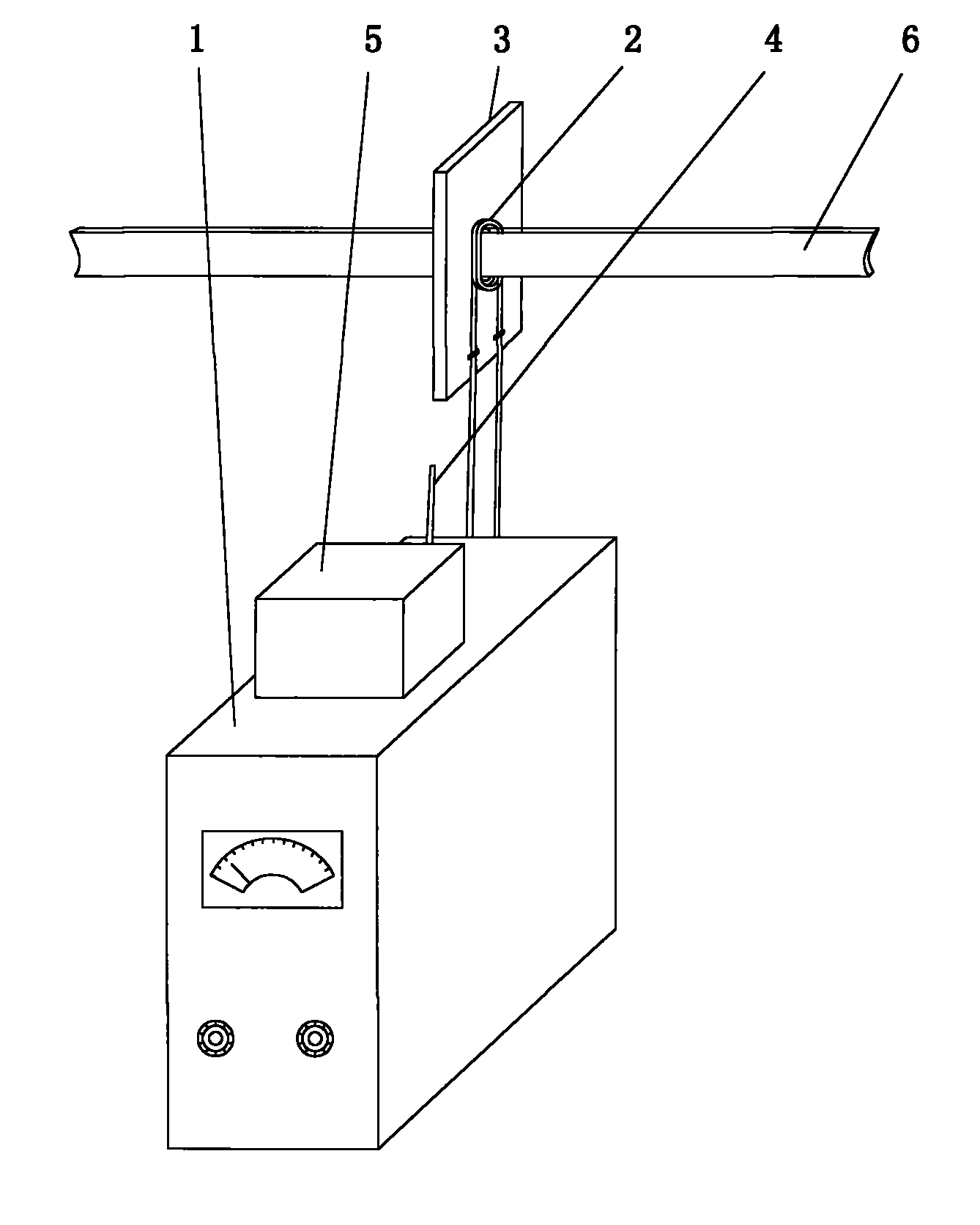

[0025] Such as figure 1 As shown, the rapid steel heating device of the present invention includes a high-frequency power supply 1 , a high-frequency heating coil 2 electrically connected to the high-frequency power supply 1 , an automatic temperature control device 5 , and a temperature sensor 4 electrically connected to the automatic temperature control device 5 .

[0026] The high-frequency heating ring 2 includes an opening that allows the heated steel to pass through without contact, and the high-frequency heating ring 2 is fixedly connected to a support body (not shown in the figure, the support body can be a frame structure of a production line or is specially designed for installing the heating ring On the heating ring fixed frame 3 that is connected to the bracket of the fixed frame, etc.

[0027] The heating ring fixing frame 3 includes a heat-resistant insulating material surrounding the high frequency heating ring 2, so that the high temperature of the heating ring...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com