Precision measurement method of nanometer clearance in nanostructure based on atomic force microscope

An atomic force microscope and nano-gap technology, which is applied to measuring devices, instruments, and electrical devices, can solve the problem of not being able to obtain the true height of the nano-suspension gap of the target structure to be measured, and achieve the effect of eliminating measurement errors and high-resolution measurement

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0033] The precise measurement method of the nano-gap in the nano-structure based on the atomic force microscope of the present invention will be described in detail below with reference to the embodiments and the accompanying drawings.

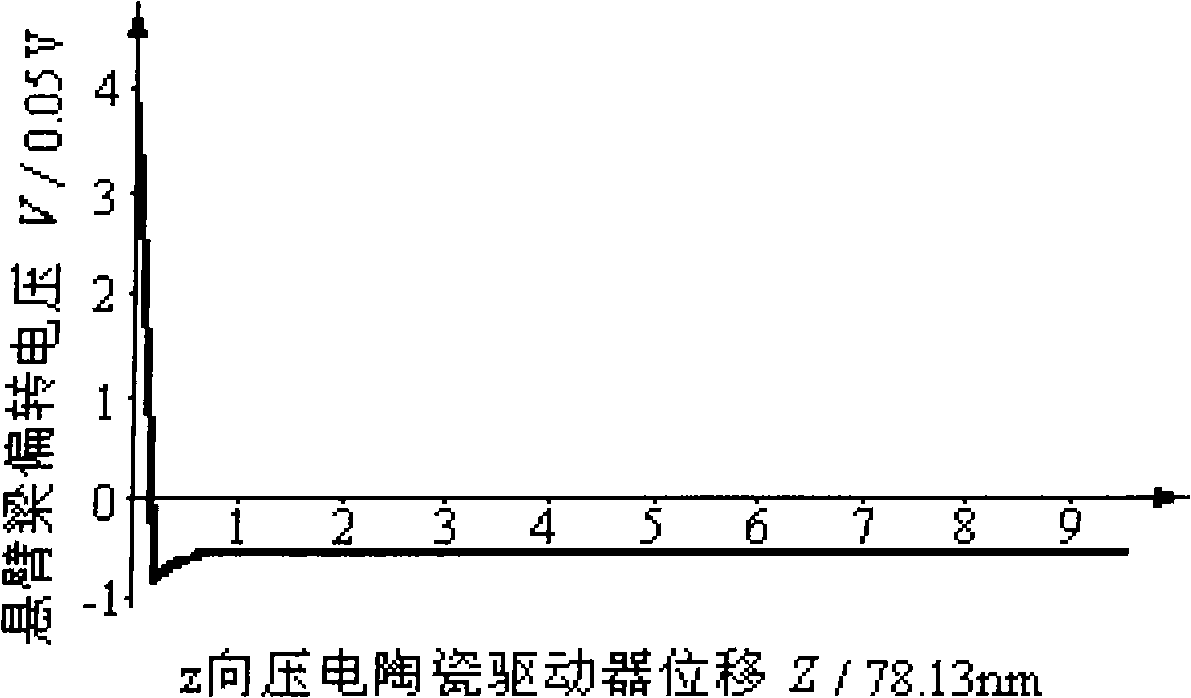

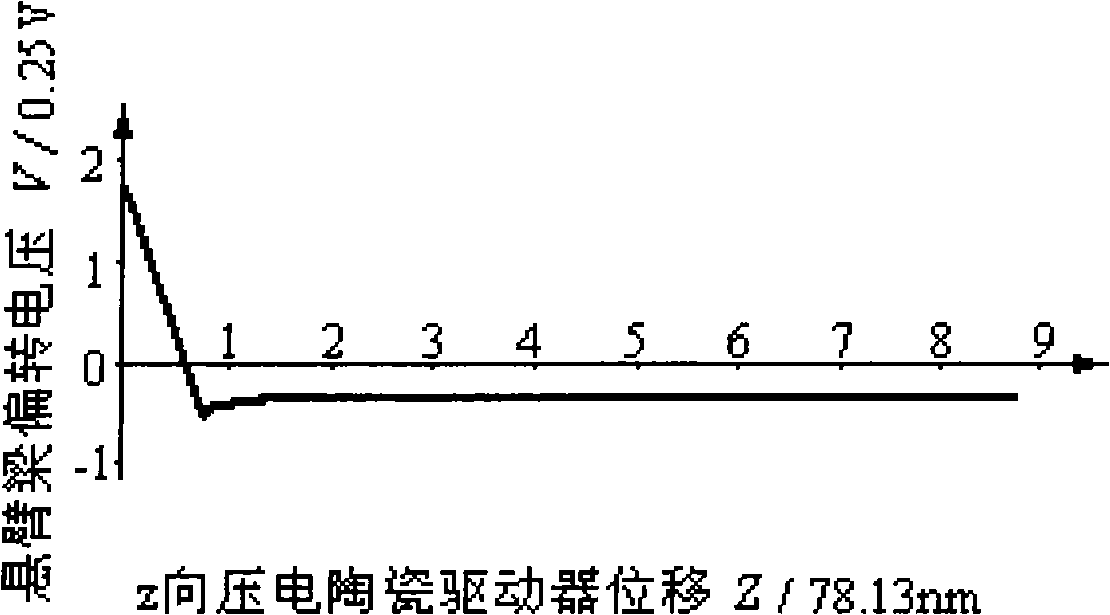

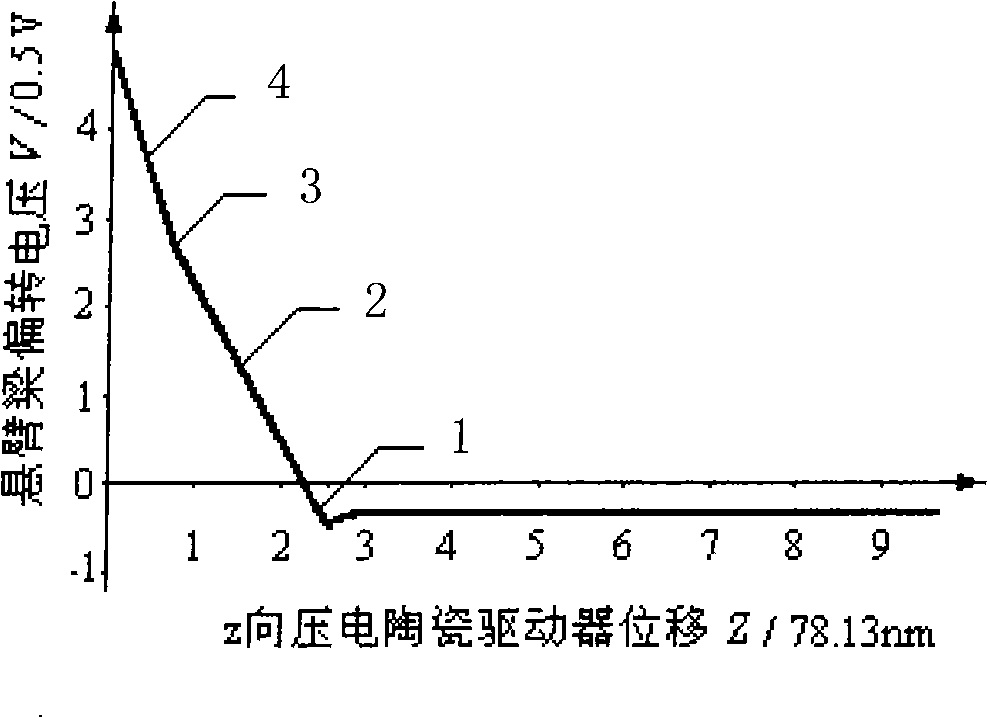

[0034] The method of the present invention is mainly realized based on AFM (atomic force microscope), and the elastic coefficient of the micro-cantilever beam of the atomic force microscope needs to be known. After each adjustment of the reflected laser signal of the atomic force microscope micro-cantilever, its sensitivity must be calibrated, and the calibration can be performed on the surface of a flat sample such as diamond or sapphire (hardness can be regarded as infinite).

[0035] The precise measurement method of the nano-gap in the nanostructure based on the atomic force microscope of the present invention firstly scans and measures the central area of the upper surface of the sample to be tested, and positions the needle tip at the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com