Batteries plate thickness on-line measurement method utilizing baseband thickness for self-calibration

A battery plate and measurement method technology, applied in the direction of electrode manufacturing, measurement devices, optical devices, etc., can solve the problems of inability to realize online real-time automatic calibration, low measurement accuracy, etc., to eliminate long-term drift errors, improve accuracy, eliminate The effect of measurement error

Active Publication Date: 2008-11-19

SUZHOU JIANGJIN AUTOMATION TECH

View PDF0 Cites 25 Cited by

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

The purpose of the present invention is to provide an online measurement method for battery plate thickness using baseband thickness self-calibration to overcome the defect of low measurement accuracy due to the inability to realize online real-time automatic calibration in the prior art

Method used

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

View moreImage

Smart Image Click on the blue labels to locate them in the text.

Smart ImageViewing Examples

Examples

Experimental program

Comparison scheme

Effect test

specific Embodiment approach 1

specific Embodiment approach 2

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More PUM

Login to View More

Login to View More Abstract

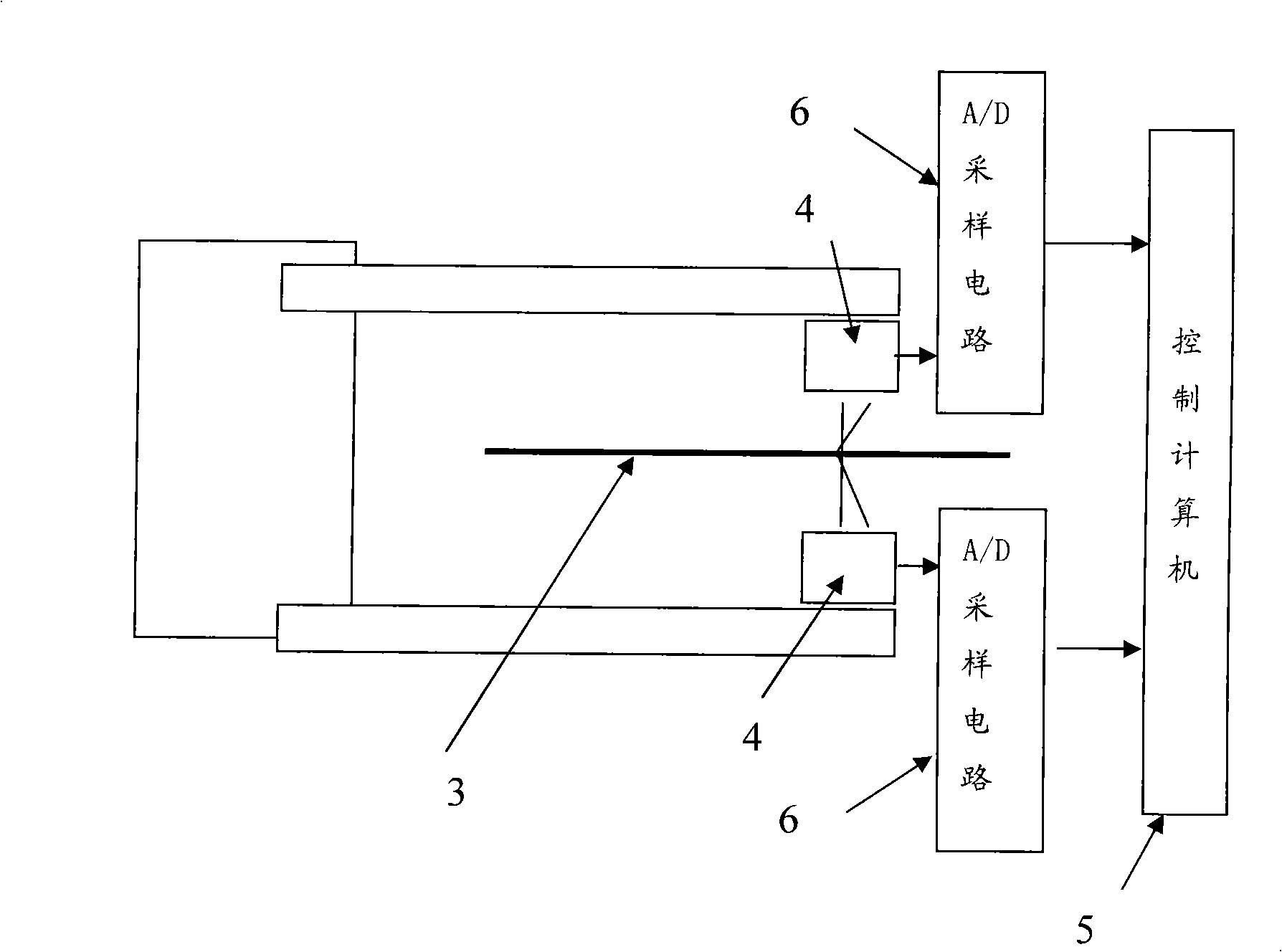

Disclosed is an on-line measurement method of battery pole plate thickness, which utilizes the thickness of a base band for automatic calibration, and the invention relates to a method for on-line measurement of battery pole plate thickness by adopting the laser differential detection. The method overcomes the defect of low measuring precision of the prior art due to the failure of on-line real-time automatic calibration. The method adopts the following steps that: a battery pole plate moves on a coated paper production line with constant speed; two laser displacement transducers arranged above the upper surface and under the lower surface of the battery pole plate respectively measure the distance value thereof relative to the battery pole plate; the program in a computer is controlled for calculating base band sampled data and SUMB of the two laser displacement transducers at the same time; the program in the computer is controlled for calculating hits in a coating area and SUMM of the two laser displacement transducers at the same time; and the program in the computer is controlled for calculating the thickness of the battery pole plate according to the formula of (SUMM-SUMB) xK+Db, wherein K is a constant; and Db is the base band thickness.

Description

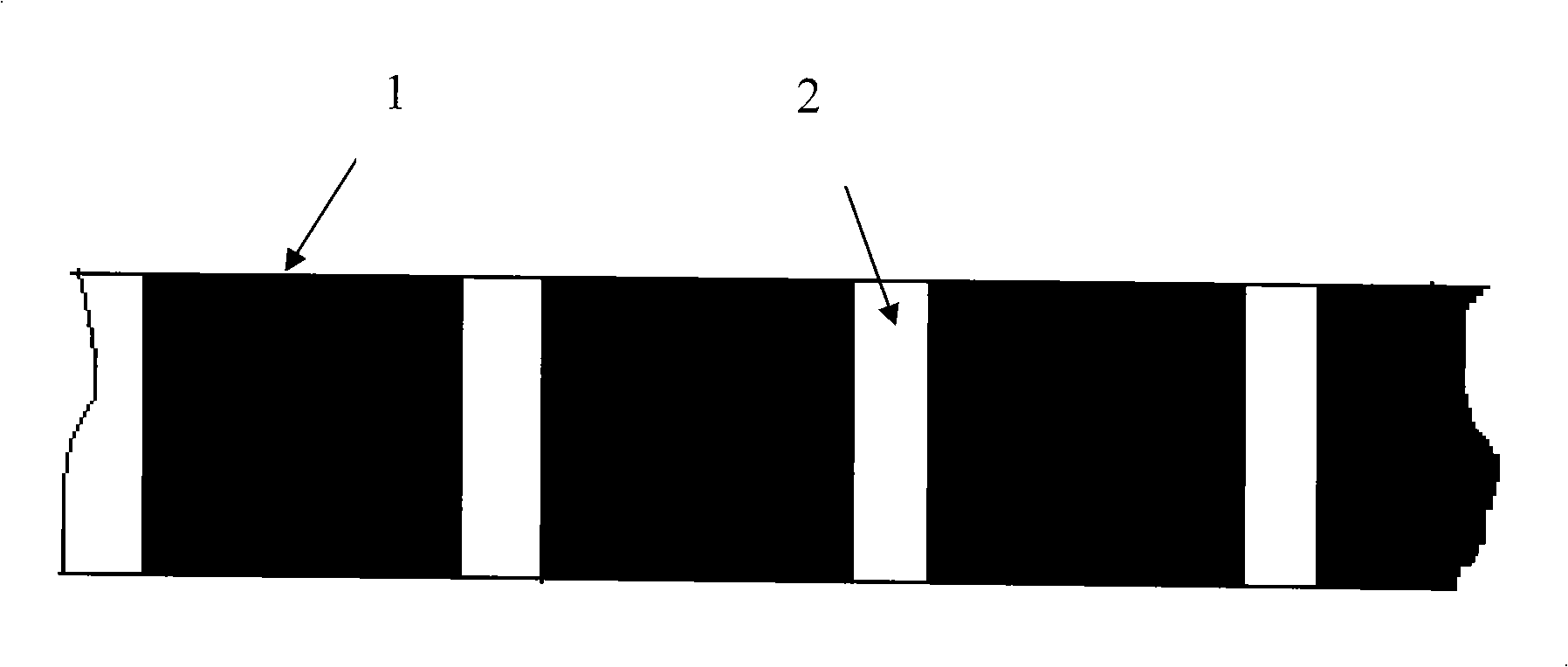

On-line measurement method of battery plate thickness using baseband thickness for self-calibration technical field The invention belongs to the field of lithium-ion battery pole plate processing, and in particular relates to a method for realizing on-line measurement of battery pole plate thickness by using laser differential detection. Background technique The battery plate is a material for the production of lithium-ion compound batteries. As shown in Figure 2, it is a continuous strip product with a thickness of only tens of microns to 500 microns. Its surface is divided into layers coated with lithium-ion compounds. Cloth part 1 and base tape part 2 not coated with substance. It is the core material for the production of batteries, and the control accuracy of the thickness of the battery plate directly affects the quality of battery products. Therefore, accurate real-time on-line measurement and control of the thickness of the battery plate has very important practic...

Claims

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More Application Information

Patent Timeline

Login to View More

Login to View More Patent Type & Authority Applications(China)

IPC IPC(8): G01B11/06H01M4/04

Inventor 何平杨旭东蔄元臣

Owner SUZHOU JIANGJIN AUTOMATION TECH

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com