Ultra high power direct-current arc furnace deoxidation furnace-protective agent, making method and use thereof

A DC electric arc furnace and furnace protection agent technology, applied in the field of deoxidation furnace protection agent, can solve the problems of furnace lining life and smelting yield that cannot meet the requirements, so as to improve the yield of all iron, good slag hanging on the furnace wall, and increase viscosity and the effect of alkalinity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

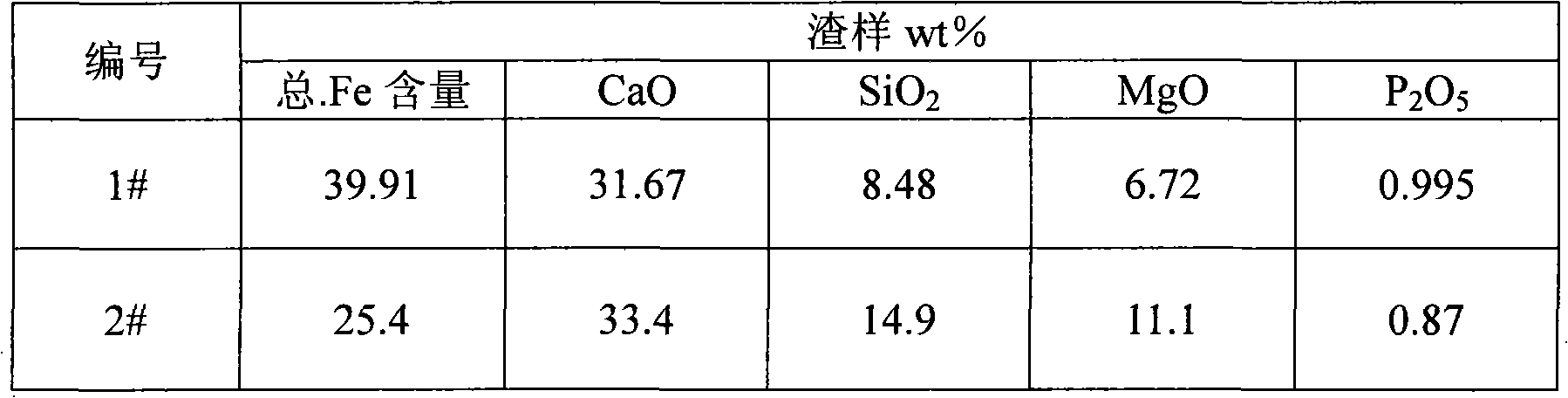

[0021] The substantive features and remarkable progress of the present invention will be further described below through the elaboration of specific examples, but the present invention is by no means limited to the examples.

[0022] The composition of the ultra-high power direct current electric arc furnace protection agent provided by the present invention is as shown in table 2

[0023] Table 2 The proportion of the improved electric furnace protection agent provided by the present invention is (wt%)

[0024] MgO

SiC

Metal.Al

CaO

M.Fe

h 2 o

Total C

1

45.13

16.20

3.30

7.47

6.10

0.10

21.70

2

50.20

17.20

4.20

5.55

5.80

0.15

16.80

3

48.10

18.50

4.10

6.78

6.00

0.12

16.40

[0025] Among them, the weight ratio of metal aluminum, silicon carbide, metal iron and graphite is 1:4~6:1~2:4~6, ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com