Microcomputer control multiline cutting machine

A multi-wire cutting machine and microcomputer control technology, which is applied in the direction of manufacturing tools, grinding machines, fine working devices, etc., can solve the problem of low work efficiency and other problems

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

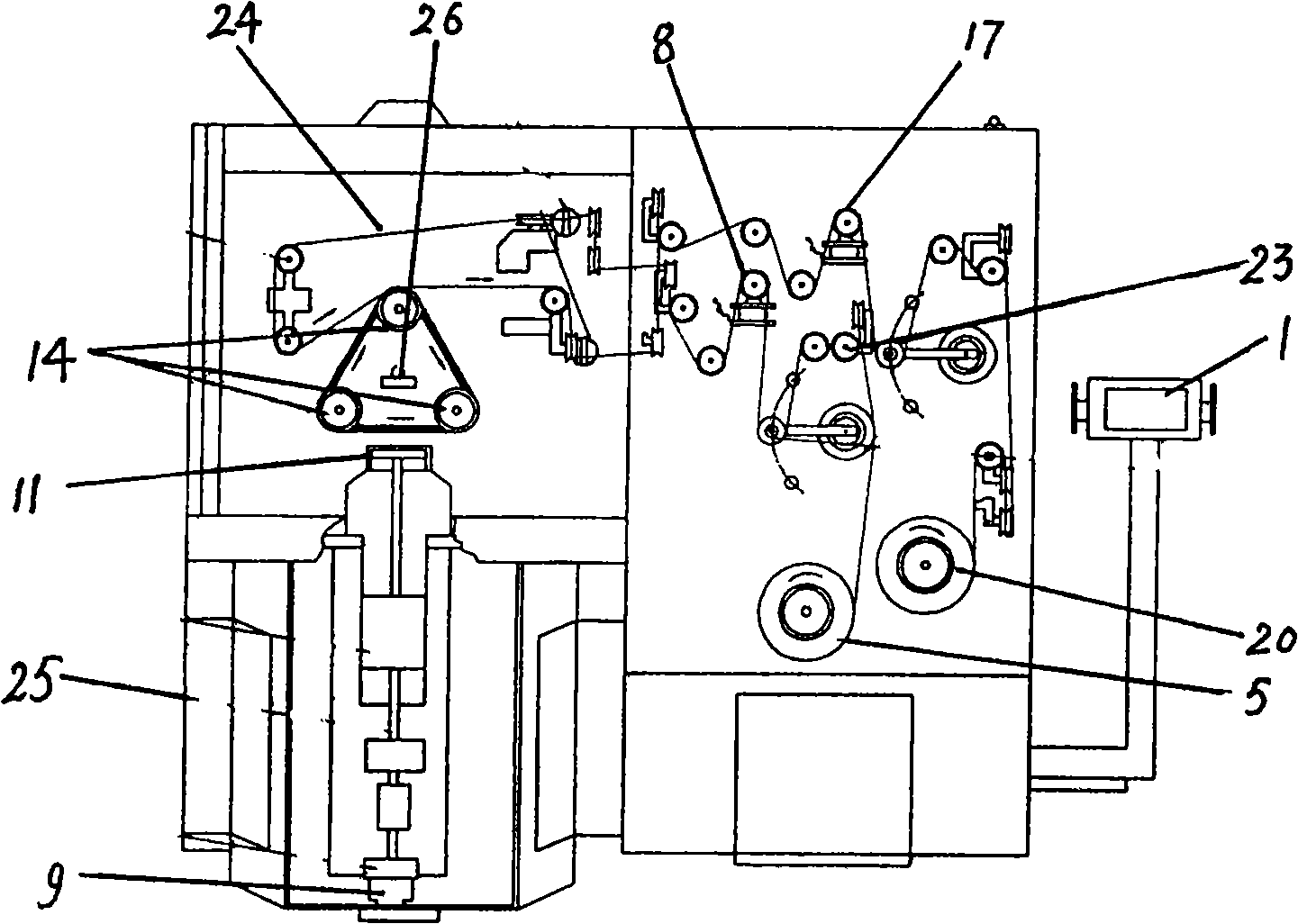

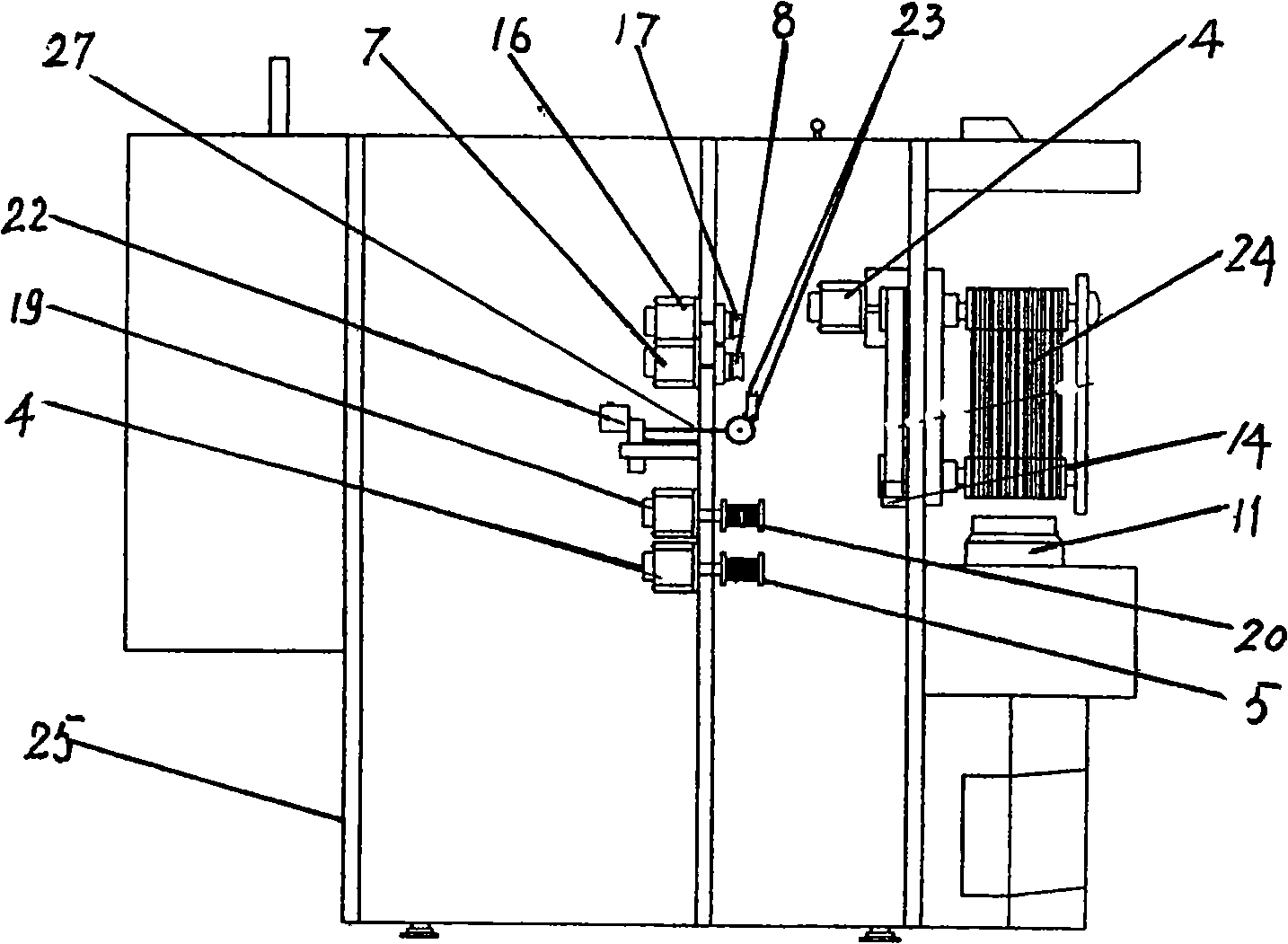

[0011] The present invention will be further described below in conjunction with the embodiments and accompanying drawings.

[0012] see Figure 1-Figure 3 , a microcomputer-controlled multi-wire cutting machine, which includes a frame 25, a workbench 11, a metal wire 24, and a grinding liquid supply mechanism. The touch display screen 1 is set, the main substrate programming controls the CPU module 2 to control the servo amplifier through the optical fiber, and the servo amplifier controls the servo motor. At least six servo amplifiers and six servo motors are installed in the rack 25, that is, servo amplifier 1 3 and servo amplifier 2 6. Servo amplifier three 9, servo amplifier four 12, servo amplifier five 15, servo amplifier six 18 and servo motor one 4, servo motor two 7, servo motor three 10, servo motor four 13, servo motor five 16, servo motor six 19. The workbench 11 is set in the frame 25, its lifting is controlled by the servo motor 3 10, and three rotating rollers...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Parallelism | aaaaa | aaaaa |

| Fineness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com