Device for scrubbing metal pipe inner wall

A technology for metal pipes and steel brushes, which is applied in the direction of workpiece clamping devices, brushes, brush bodies, etc., can solve the problems of metal pipe collapse and deformation, failure to meet the quality requirements of brushing, etc., to prevent collapse and deformation, repair deformation, and simplify Institutional Effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0009] The specific implementation manner of the present invention will be described below in conjunction with the accompanying drawings.

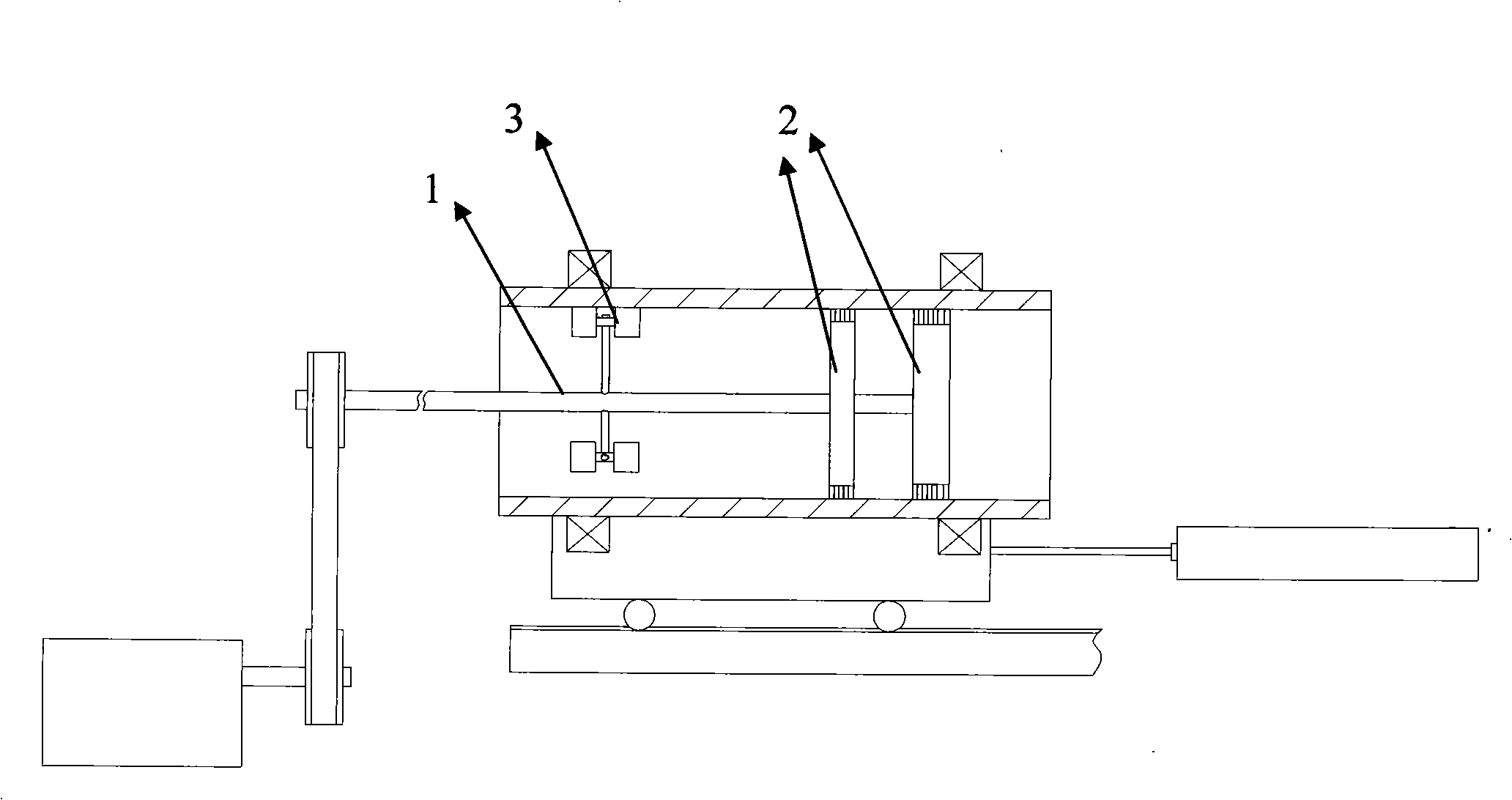

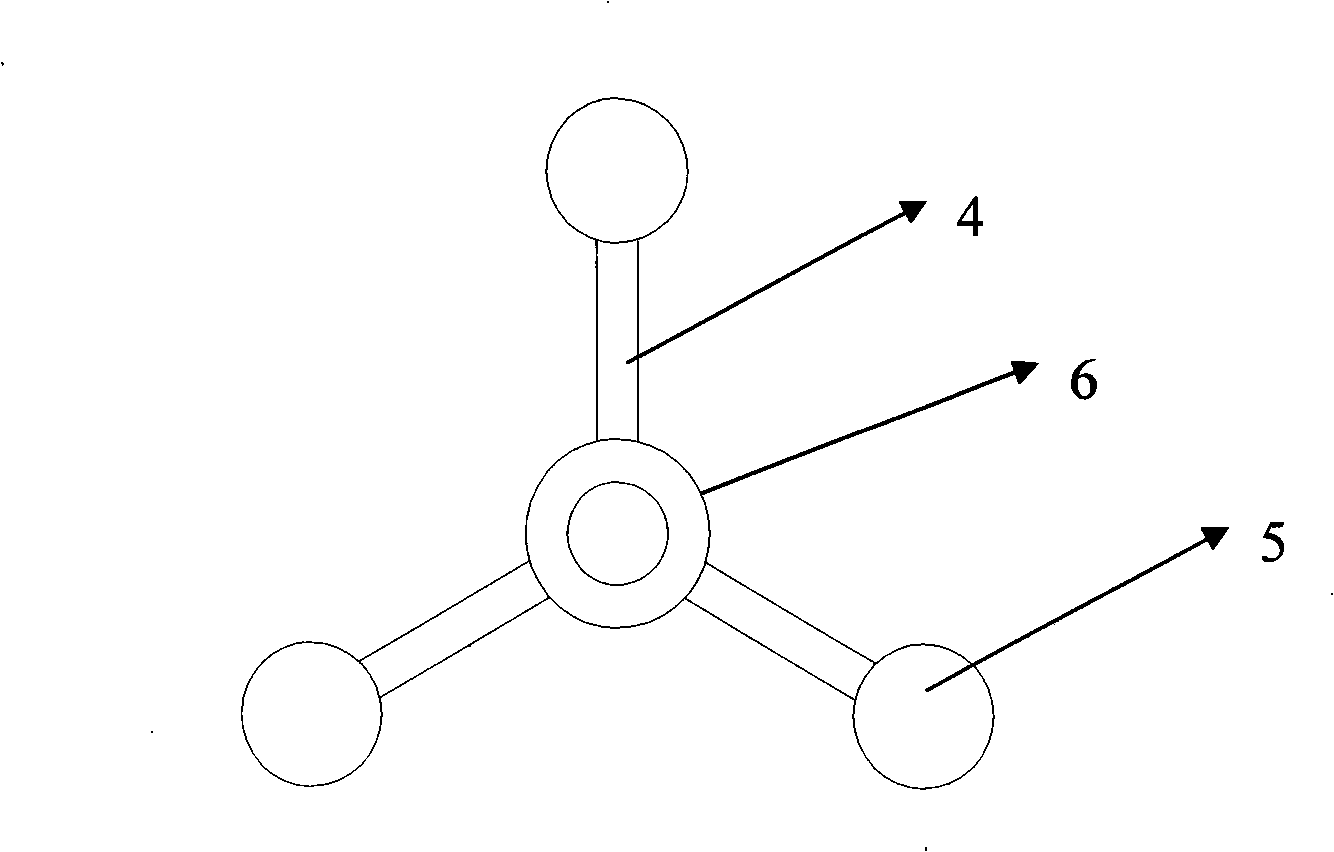

[0010] Such as figure 1 As shown, a scrubbing device for the inner wall of a metal pipe is provided with a main shaft 1 placed inside the metal pipe, and a clamping mechanism is arranged outside the metal pipe. A steel brush 2 is installed on the main shaft 1 . A three-way support frame 3 is also installed on the main shaft 1, and the three-way support frame 3 has three poles 4. The outer ends of the three poles 4 are provided with three rollers 5 on the same circular line, and the inner ends of the three poles 4 are fixed. on the bushing 6. A rotating mechanism is connected with the main shaft 1, and the rotating mechanism is transmitted to the main shaft by a motor through a belt and a pulley. The metal pipe is fixedly placed on the sliding frame, and the sliding frame is driven by the oil cylinder to complete the reciprocating motion...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com