Automobile front floor and automobile

A car front floor and front floor technology, which is applied in the field of vehicles, can solve the problems of complex front floor structure, common use, and increased installation of web processes, etc., to achieve the effects of preventing collapse and deformation, protecting personal safety, and reducing stress

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

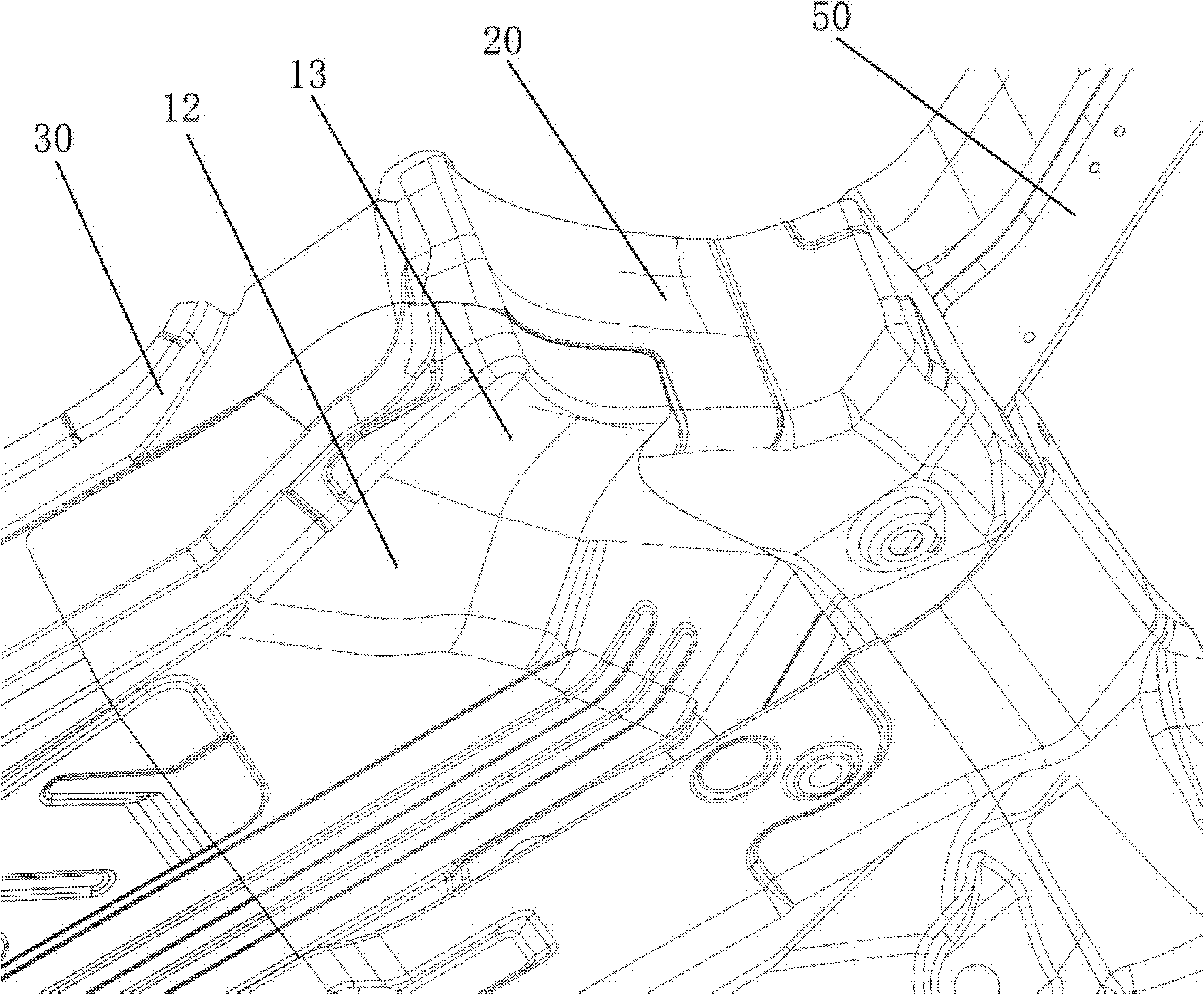

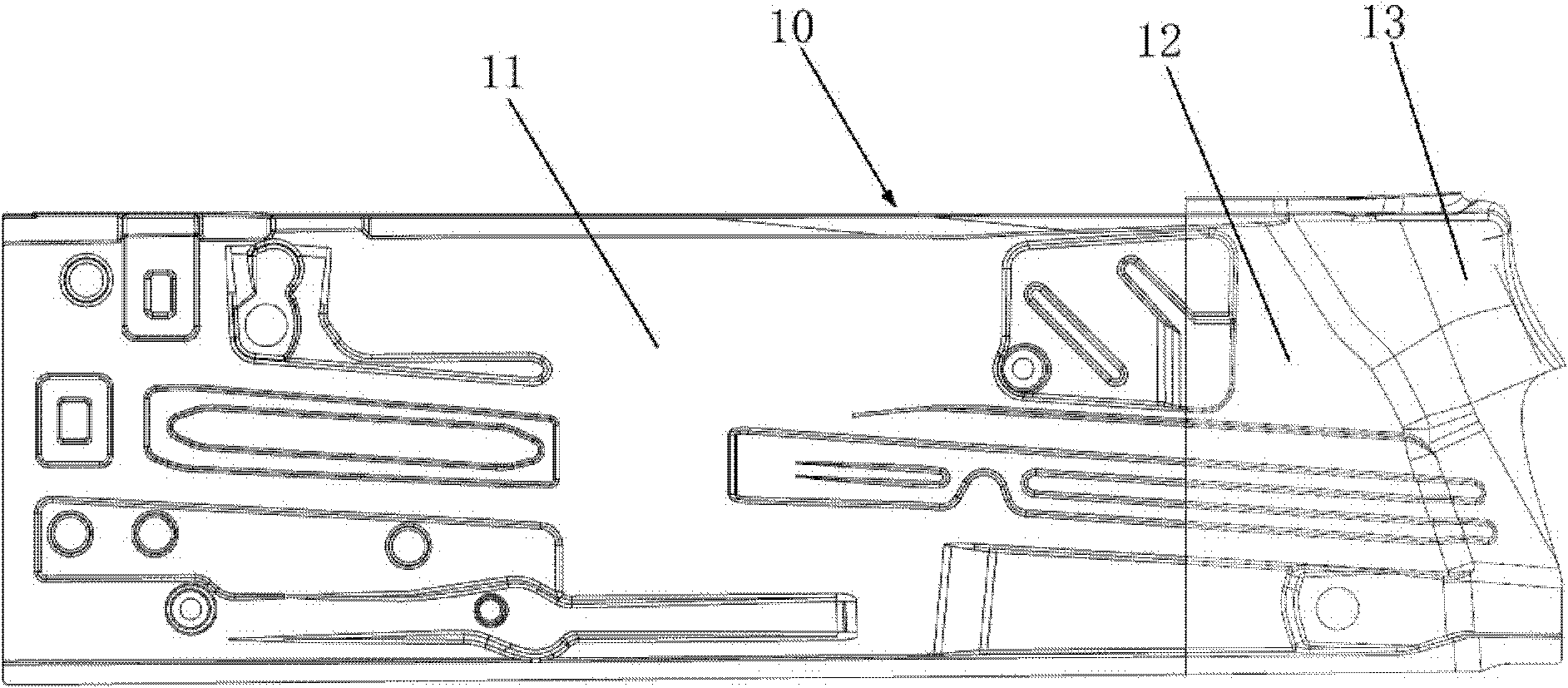

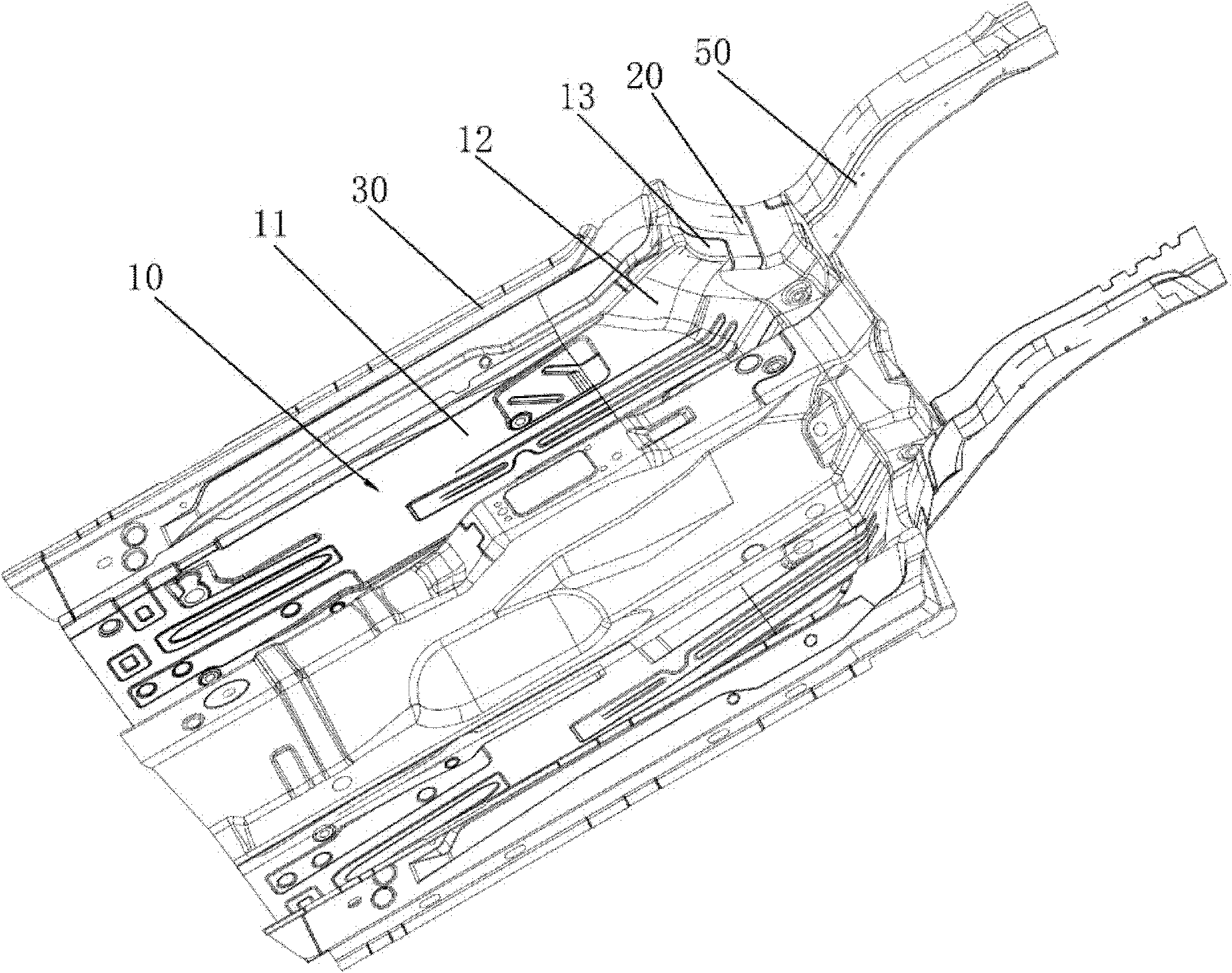

[0024] The specific embodiments of the present invention will be described in detail below with reference to the accompanying drawings. It should be understood that the specific embodiments described herein are only used to illustrate and explain the present invention, but not to limit the present invention.

[0025] In the present invention, unless otherwise stated, the use of directional words such as "front and rear" generally means that, with respect to the vehicle body, the same direction as the vehicle's running direction is "front", and the opposite direction is "front". The direction is "rear", and similarly, the azimuth "up and down" used is also relative to the "up and down" direction of the car body.

[0026] As mentioned above, the connection strength between the front floor of the prior art and other components is insufficient. Therefore, an improved structure of the front floor of an automobile is required to overcome the above-mentioned defects.

[0027] see f...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com