High-temperature acid-resistant alpha-amylase mutant strain and construction method thereof

A construction method and amylase technology, applied in the field of bioengineering, can solve problems such as loss of enzyme activity and inability to adapt, and achieve the effects of stable enzyme activity, saving industrial grain, good thermal stability and acid stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0030] The following examples are used to further illustrate the present invention. The following examples are illustrative and not restrictive. The following examples cannot be used to limit the protection scope of the present invention.

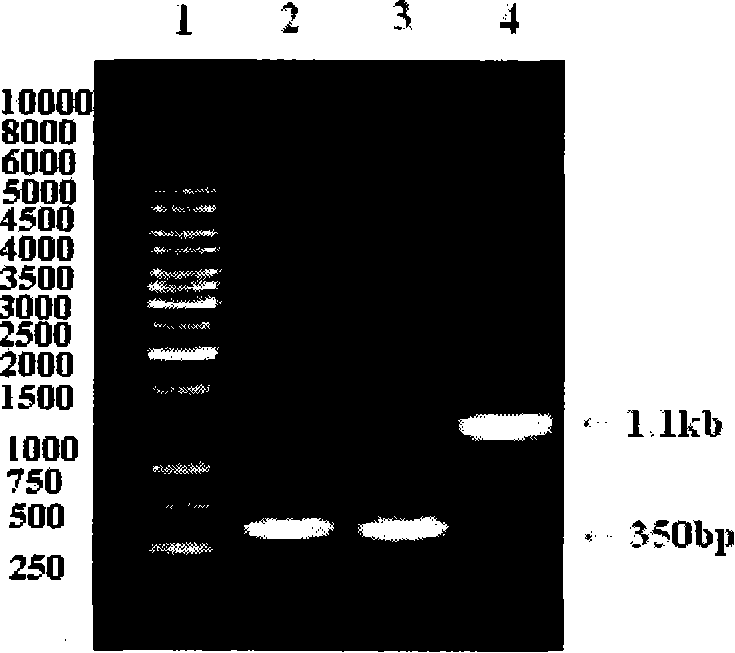

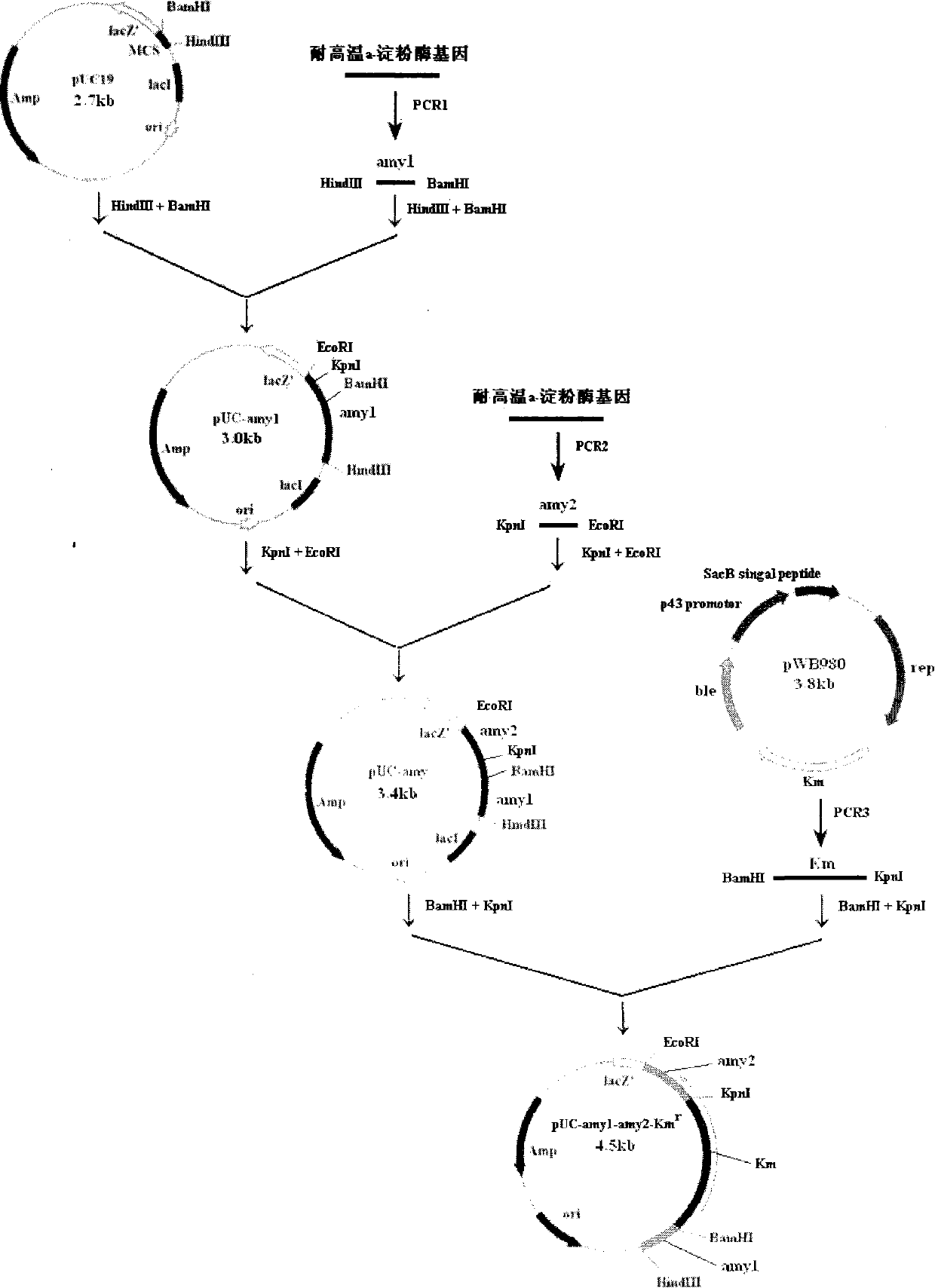

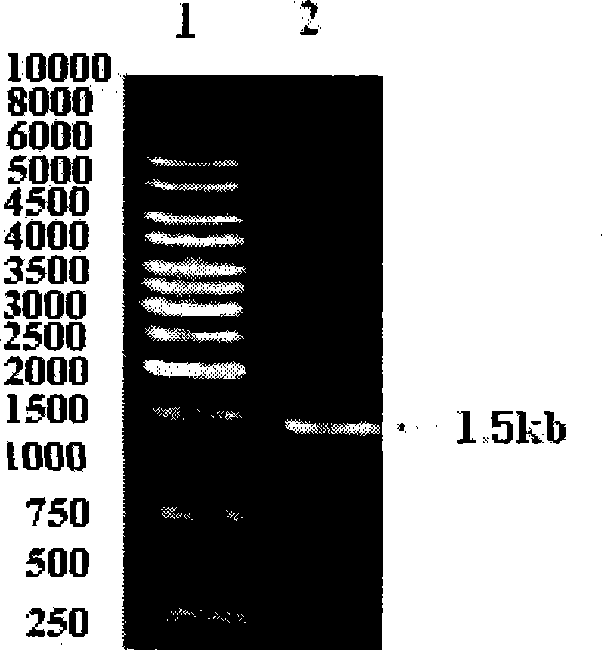

[0031] The present invention combines the obtained high-temperature acid-resistant alpha-amylase (acid-resistant modification of alpha-amylase and its secretion expression in Bacillus subtilis. Food and Fermentation Industry, 2005, 31(10): 33-36. High-temperature alpha-amylase and its preparation method, patent application number: 200510013865.2), in order to improve the high-temperature resistant alpha-starch isolated from Bacillus licheniformis (China Industrial Microbial Culture Collection and Management Center, CICC, preservation number, 10181) The acid resistance of the enzyme is a mutant gene obtained by changing L-leucine at position 134 of the mature peptide of this gene to L-arginine and changing L-serine at position 320 to L-alanine; ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com