Polythiofuran-carbon nanotube composite photosensitive film material and preparation thereof

A carbon nanotube composite and carbon nanotube technology, which is applied in the field of polythiophene-carbon nanotube composite photosensitive film materials and their preparation, can solve the problem of not many composite photosensitive film materials, and achieves simple process and excellent solubility. , the effect of improving utilization

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0035] Add 500mg of multi-walled carbon nanotubes to 150mL of concentrated sulfuric acid and concentrated nitric acid in a mixed strong acid solution with a volume ratio of 3:1, ultrasonically oscillate for 4 hours, pour into deionized water, and stand for more than 12 hours, filter and wash with water To neutrality, then dry to obtain chemically etched carbon nanotubes; under the protection of nitrogen, place 400 mg of the above-mentioned carbon nanotubes with carboxylic acid in excess thionyl chloride to reflux for 36 hours, after the reaction is completed, distill under reduced pressure Remove excess thionyl chloride, and dry in vacuo to obtain acid-chlorinated carbon nanotubes; then disperse 200 mg of the above-mentioned acid-chlorinated carbon nanotubes in anhydrous acetone, and add dropwise 10 mL of 0.01 g / mL at 65 ° C The acetone solution of dodecylamine, the dropping time is not less than 60-70 minutes, continuous reaction for 12 hours, centrifugal filtration and water ...

Embodiment 2

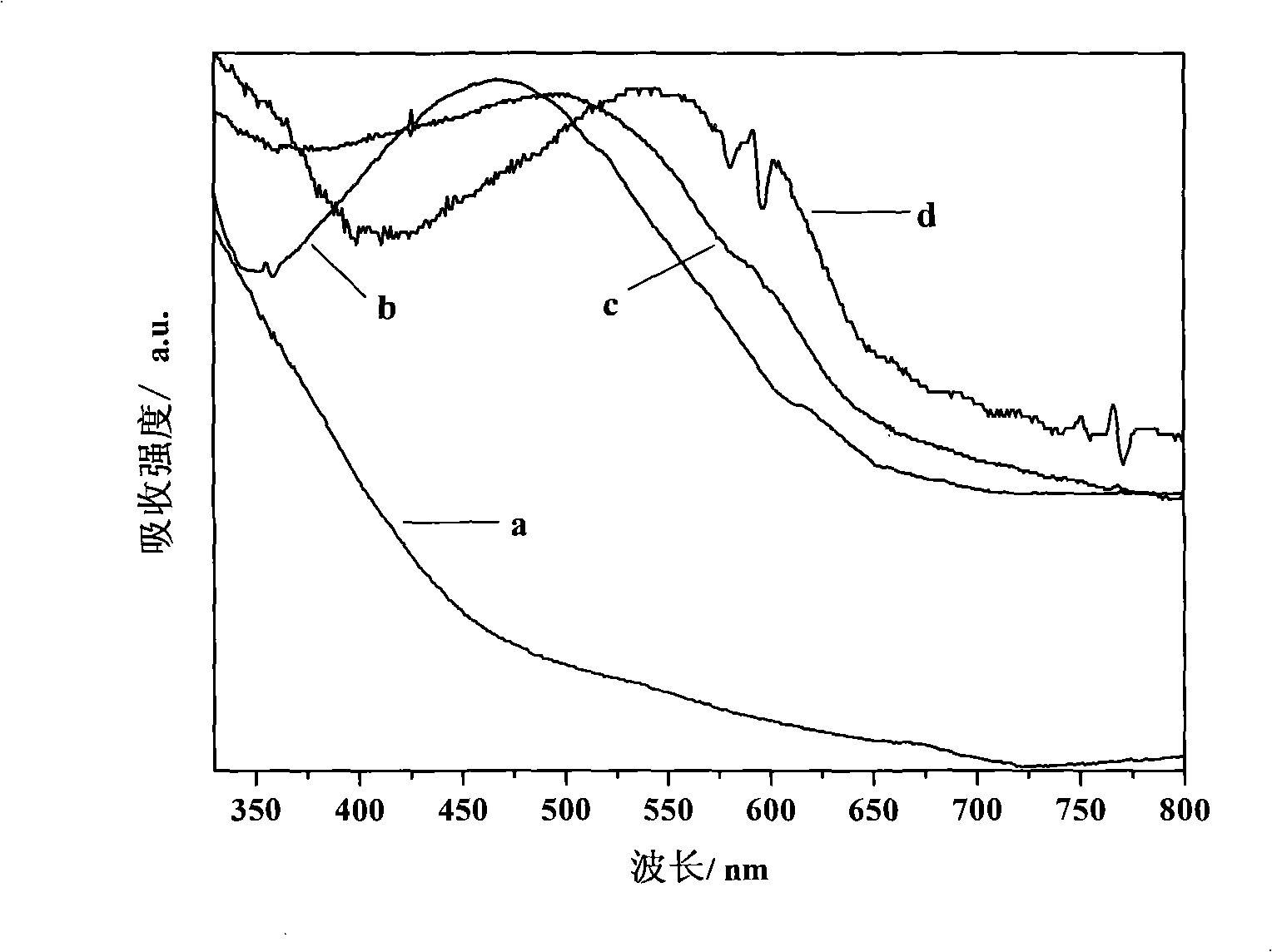

[0039]Same as Example 1, but the weight ratio of carbon nanotubes to poly(3-hexylthiophene) was changed from 1:6 to 1:3. The photosensitive performance of the poly(3-hexylthiophene) / carbon nanotube film is shown in FIG. 4 .

Embodiment 3

[0041] Same as Example 1, but the weight ratio of carbon nanotubes to poly(3-hexylthiophene) was changed from 1:6 to 1:1.

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| concentration | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com