Non-halide thin film for aeration and preparation thereof

A non-halogen, film technology, applied in the field of non-halogen film for blowing and its preparation, can solve the problems of no polyolefin plastic material, unsuitable for high-frequency welding processing, poor physical properties, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

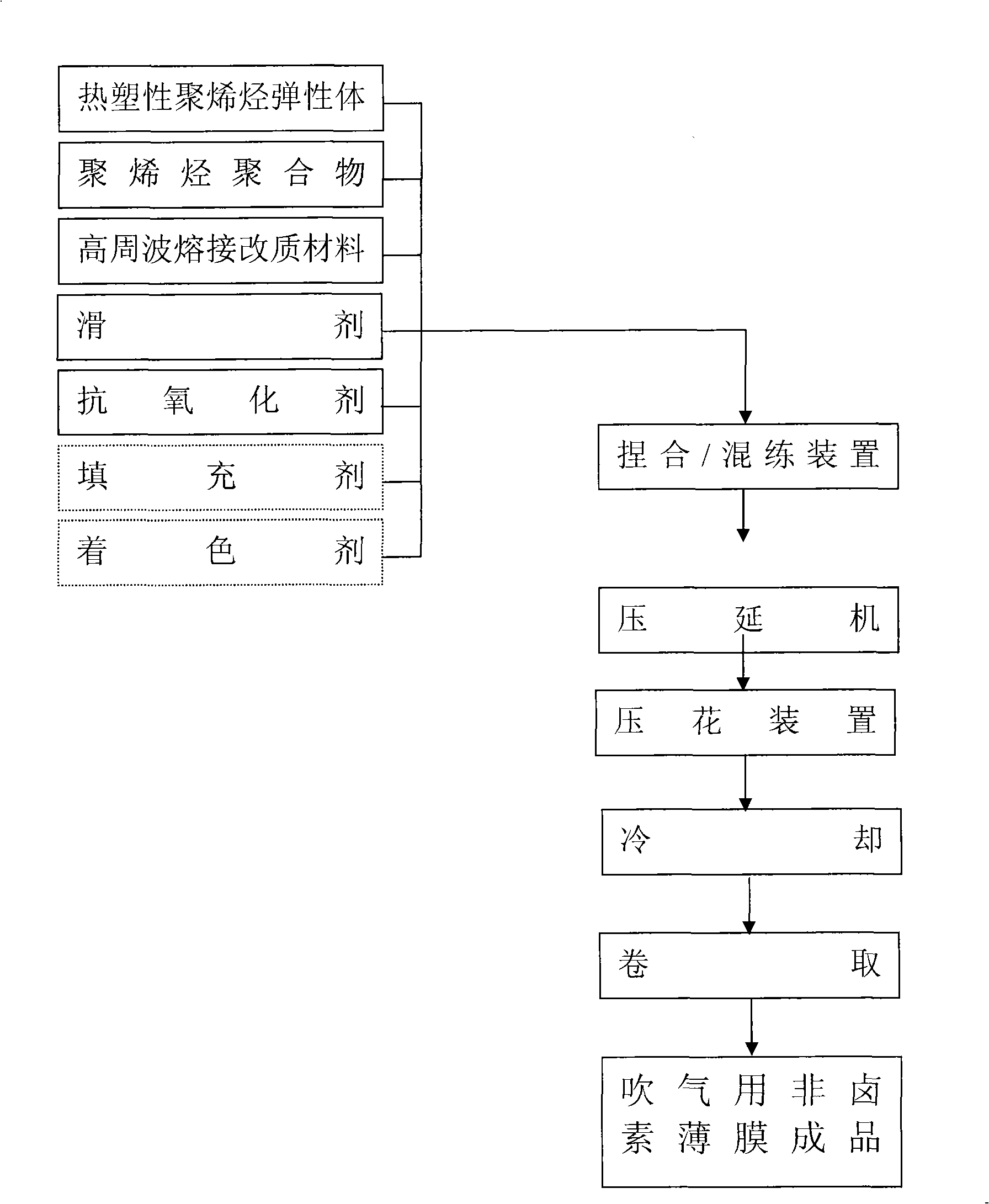

Image

Examples

Embodiment ( 1

[0024] The design formula is as follows in Table 1:

[0025] raw material name

[0026] On-line trial production on the tape machine. After weighing the raw materials according to the design formula in Table 1, put them into the kneading / mixing function of the 10,000-horsepower machine (banbury mixer) for gelation and aging. The operation time is 90 seconds, and then the mature rubber Send it to a kneader (roller) with a set temperature of 150°C for uniform kneading, and then feed the rubber into a calender with an operating temperature of 160-190°C in a continuous operation mode, and roll it into The hot-melt adhesive film with a thickness of 0.30mm is pressed by an embossing wheel, cooled to room temperature by a cooling wheel, and finally coiled by a coiler to obtain a non-halogen film product for blowing.

Embodiment ( 2

[0028] The design formula is as follows in Table 2:

[0029] raw material name

[0030] After weighing the raw materials according to the formula in Table 2, knead and process them with a two roll mil in the laboratory. The temperature of the rolls: 145°C for the front roll and 140°C for the rear roll. The kneading time: 10 minutes. Finally, adjust the gap between the two wheels to make the rubber material rolled to the required thickness, and finally take out the film to cool it, and make a non-halogen film for air blowing with a thickness of 0.30mm.

Embodiment ( 3

[0032] The design formula is as follows in Table 3:

[0033] raw material name

[0034] After weighing the raw materials according to the formula in Table 3, knead and process them with a two roll mil in the laboratory. The temperature of the rolls: 175°C for the front roll and 170°C for the rear roll. The kneading time: 10 minutes. Finally, adjust the gap between the two wheels to make the rubber material rolled to the required thickness, and finally take out the film to cool it, and make a non-halogen film for air blowing with a thickness of 0.30mm.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com