Escalator or moving pavement driving device

A technology of moving walks and driving devices, which is applied to escalators, energy efficiency, transportation and packaging of escalators. It can solve the problems of high energy consumption, short operating life, and large mechanical wear, and achieve high transmission efficiency and long operating life. The effect of long length and high motor efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

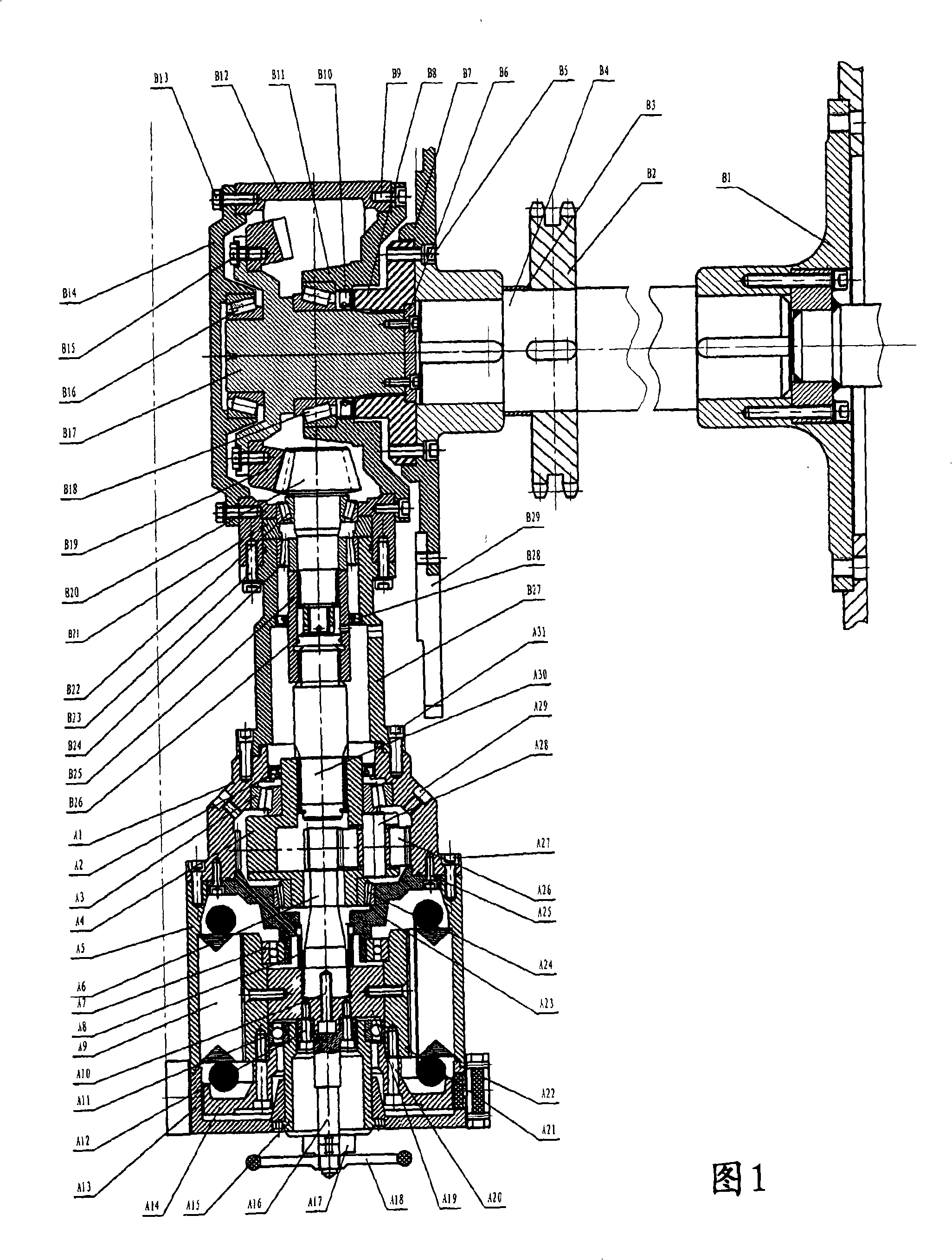

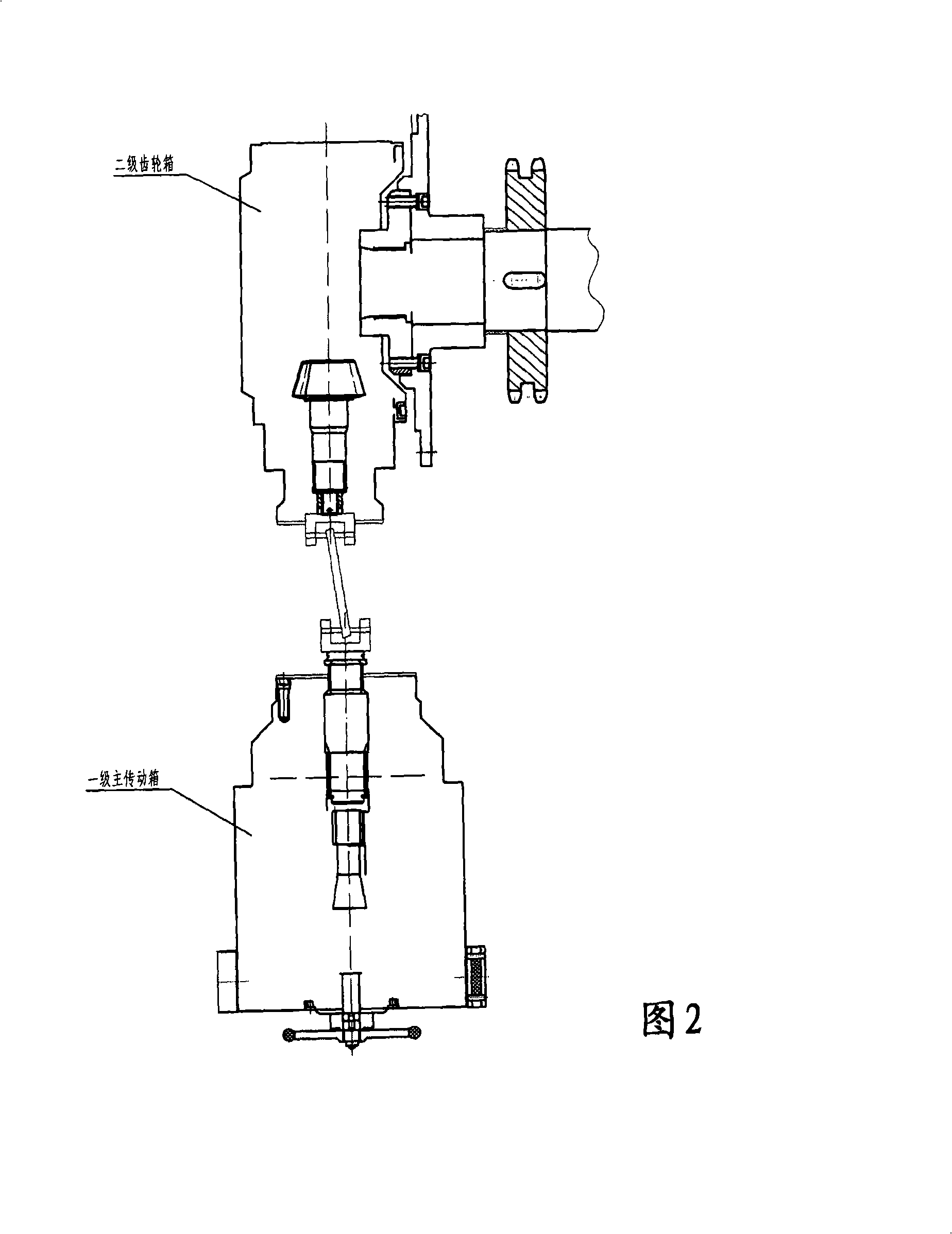

[0019] The main reference signs of the present invention are as follows

[0020] A1, ring gear housing; A2, primary lip seal; A3, front bevel gear; A4, planet carrier; A5, motor housing; A6, sun gear shaft; A7, motor front bearing; A8, mechanical seal; A9, Stator winding; A10, sun gear shaft fixing bolt; A11, motor rear bearing; A12, auxiliary shaft extension fixing bolt; A13, motor rear cover; A14, brake wheel; A15, rear hollow wheel; A16, auxiliary shaft extension; A17 , Encoder; A18, Turning handwheel; A19, Rotor triple inner spline body; A20, Brake wheel connecting bolt; A21, Permanent magnet rotor; A22, Brake; A23, Rear sealing cover; A24, Rear tapered bearing; A25, rear sealing cover fixing bolt; A26, planetary gear; A27, connecting bolt; A28, planetary gear shaft; A29, oil injection and drain bolt; A30, two-way spline connecting shaft;

[0021] B1, the right sprocket assembly; B2, the driving sprocket of the armrest belt; B3, the positioning sleeve; B4, the main drive ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com