Method for eluting and renovating soil with heavy metal-organic matter combined pollution

A technology of composite pollution and heavy metals, applied in the restoration of polluted soil, etc., can solve the problems of large amount of eluent and high repair cost, and achieve the effect of reducing the amount of eluent, small environmental risk, and reducing repair cost.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0032] Take 1g of the soil samples from the mining area in 2.5 and put them into 22ml glass centrifuge tubes with Teflon lids, add ethyl lactate of different concentrations to 5%-20% by weight in another container, and EDDS (EDDS / Cu molar ratio = 2) Solution, adjust the pH of the leaching system to neutral, and prepare it as a leaching agent. According to the dry weight of the soil, add the leaching agent to wash the soil for 24 hours according to the dry weight of the soil. Supernatant: shake at 25±1℃ for 24h, centrifuge after equilibration, take the supernatant to analyze the content of phenanthrene and pyrene by HPLC, and determine the Cu in the extract by atomic absorption 2+ Concentration, three parallels in each group, to study the extraction effect of ethyl lactate-EDDS-water (ethanol-EDDS-water) on polycyclic aromatic hydrocarbons and Cu in compound contaminated soil. The supernatant is first adsorbed by the organic adsorption resin, and then passed through the cation exch...

Embodiment 2

[0035] The basic treatment method is the same as in Example 1, and the treatment amount and reagent amount are different.

[0036] The speciation analysis adopts the EU BCR continuous extraction method, which is divided into four forms: acid extractable state, oxide-bound state, organic matter-bound state, and residue state.

[0037] The first state (exchangeable state and carbonate-bound state) (B1): Take 0.5g soil samples before and after restoration respectively, place them in a 50ml polyethylene centrifuge tube, add 20ml 0.1mol / L HAc, and shake at room temperature for 16h, 3000rpm Centrifuge for 20 minutes, take the supernatant, add 0.2ml concentrated nitric acid, and determine.

[0038]The second state (iron-manganese oxidation combined state) (B2): add 20ml 0.1mol / L NH to the upper solid phase 2 OH·HCl, shake at room temperature for 16 hours, centrifuge at 3000 rpm for 20 minutes, take the supernatant, add 0.2 ml of concentrated nitric acid, and determine.

[0039] The third...

Embodiment 3

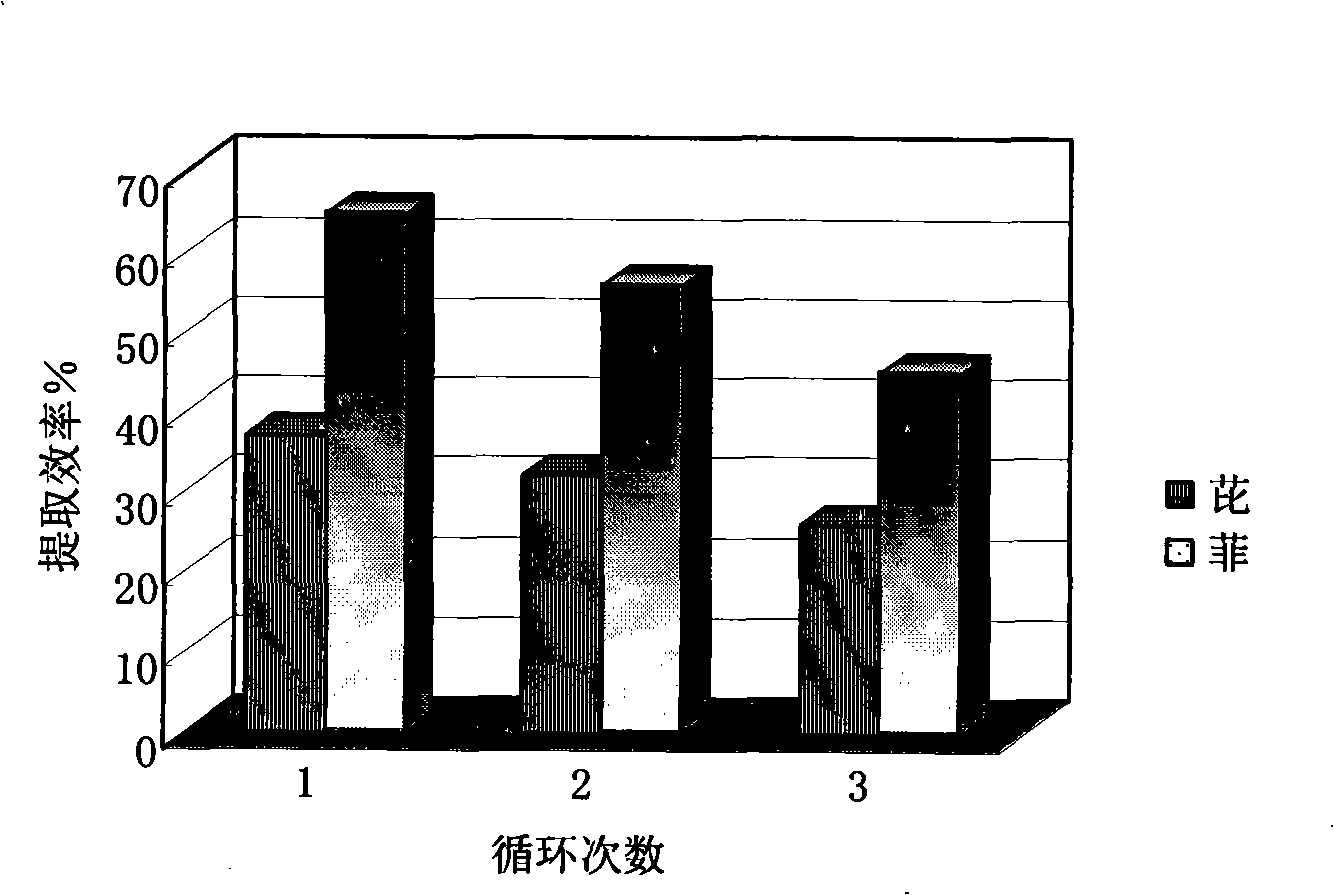

[0044] Take 1g of Tangshan copper contaminated soil in a 22ml Corex glass centrifuge tube, add 10ml of eluent (EDDS / Cu=2, ethyl lactate 20%, soil-water ratio 1:10), and use NaNO 3 The ionic strength of the adjustment system is 0.01M, and the pH of the adjustment system is 7 with NaOH and HCl. Oscillate at constant temperature for 12h. Centrifuge at 4000r / min for 10min, and take the supernatant to determine the copper content by atomic absorption. Take 0.5g of NDA-150 resin in the leachate and shake for 0.5h. The leachate after resin treatment is filtered and used for the second cycle leaching. Taking into account the loss of the eluent caused by the resin adsorption process, 0.8g of Tangshan copper-contaminated soil was taken from the 22ml Corex glass centrifuge tube for the second cycle of leaching, and the resin-treated eluent was added (soil to water ratio 1:10, Ionic strength 0.01M, pH=7). Shake at constant temperature for 12h, centrifuge at 4000r / min for 10min, and take the s...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com