Magnetic wire and recording media

A recording medium and magnetic wire technology, applied in magnetic recording, electrical recording, data recording, etc., can solve the problems of weak magnetic signal, detection by non-contact reading system, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

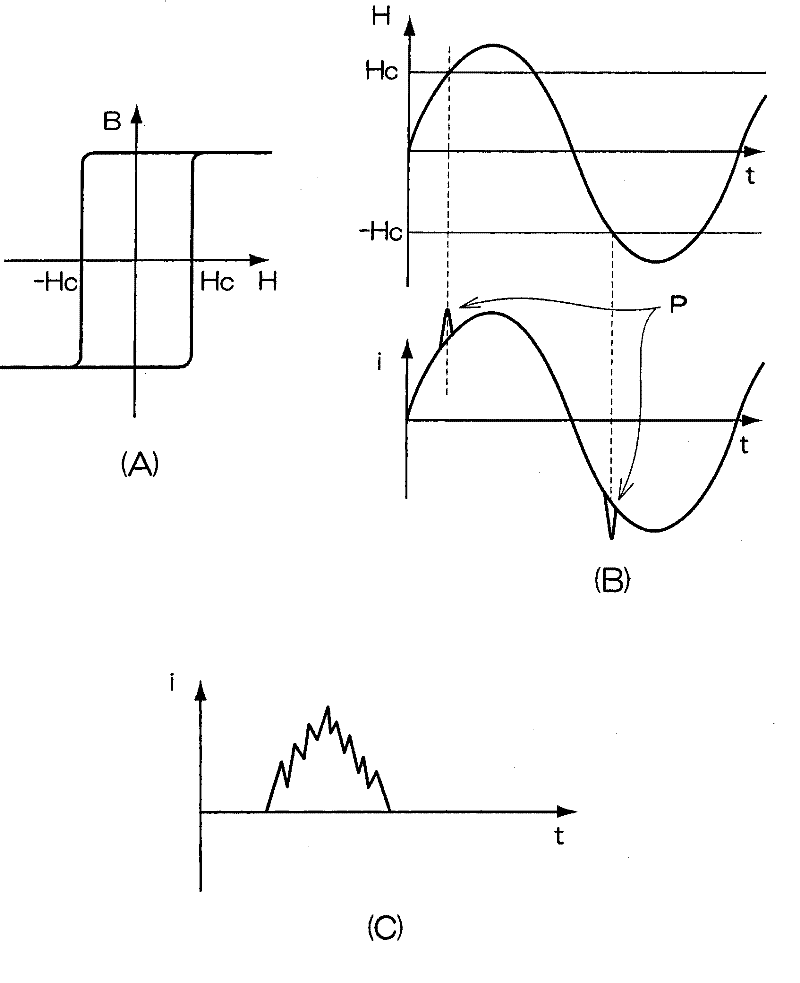

Problems solved by technology

Method used

Image

Examples

Embodiment 1

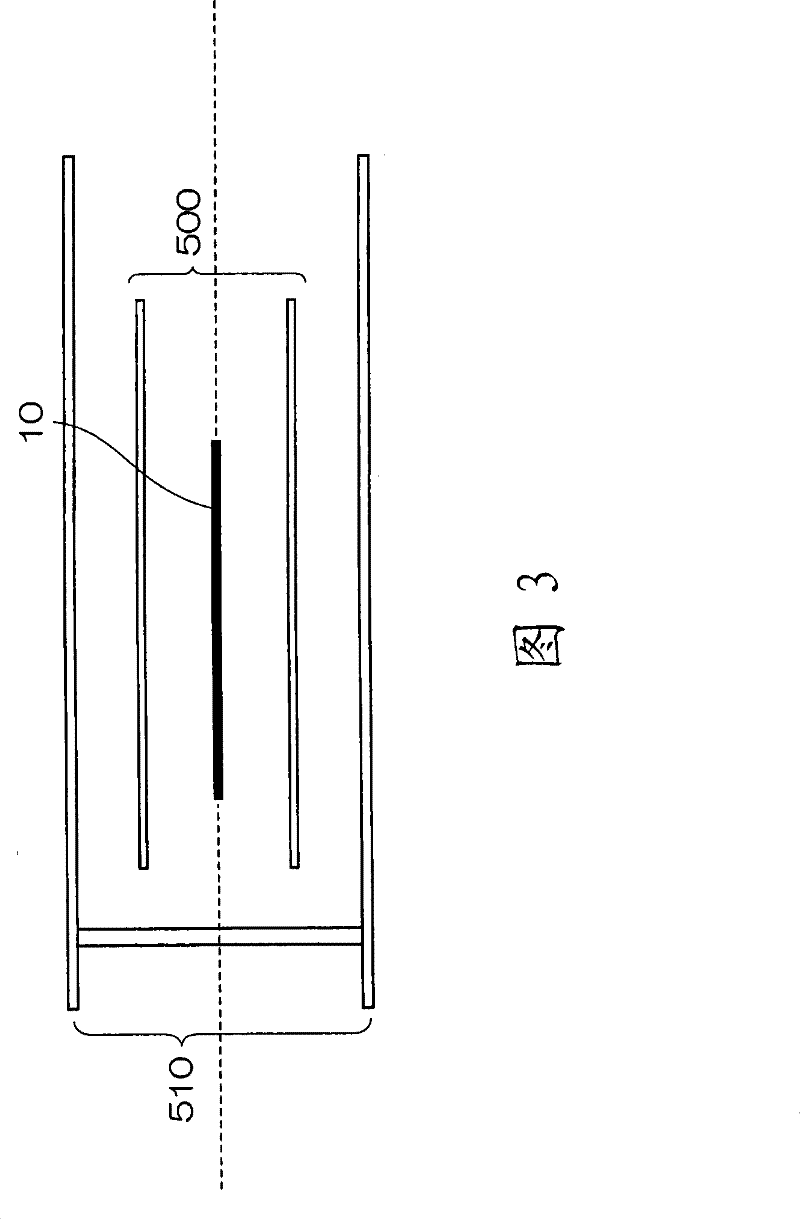

[0156] -Preparation of magnet wire-

[0157] As a magnetic metal material used as a raw material, a metal rod (Co—Fe—Si—Cr—B alloy) having a diameter of 4 mm to 5 mm is used. Composition ratios of Co, Fe, Si, Cr, and B elements contained in the metal rod were 82% by weight, 5% by weight, 6% by weight, 4% by weight, and 3% by weight, respectively.

[0158] As a glass tube filled with magnetic metal material, used by PYREX Tube made of glass (outer diameter: 10 mm, glass thickness: 1.0 mm). PYREX Glass is a trademark of Coming Glass Works in the United States, and its typical composition is: SiO 2 81% by weight, B 2 o 3 13% by weight, Na 2 O is 4 wt%, Al 2 o 3 2% by weight.

[0159] Insert the tip of the metal rod into the glass tube. Subsequently, the metal rod in the glass tube was heated with a high-frequency heating device at a frequency of 440 kHz and an input power of 1 to 2 kW to melt the metal rod in the glass tube.

[0160] In this state, the lower end of t...

Embodiment 2

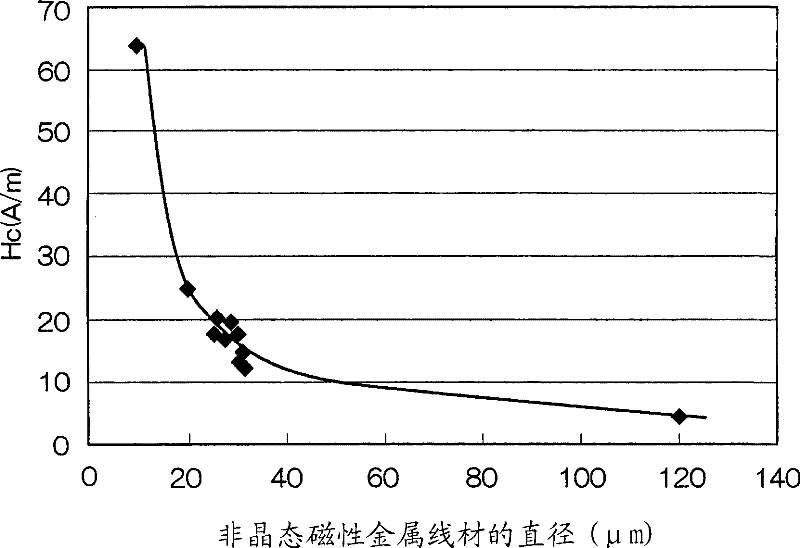

[0174] Except that the coiling speed when preparing the magnetic wire is changed to 60 to 80 m / min, the wire is prepared in the same manner as in Example 1, and the material is cut into the same length as in Example 1 to obtain a magnetic wire . Subsequently, a recording medium was prepared in the same manner as in Example 1 except that the magnetic wire obtained here was used.

[0175] The magnetic wire obtained above had a coercive force of 10.3 A / m, an average diameter of the core portion (amorphous magnetic metal wire) of 35 μm, and an average thickness of the glass coating layer of 3.6 μm. When the entire outer peripheral surface of the magnetic wire was observed with a scanning electron microscope, no exposed amorphous magnetic metal wire was observed, and it was confirmed that the glass coating layer completely covered the amorphous magnetic metal wire.

PUM

| Property | Measurement | Unit |

|---|---|---|

| coercivity | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com