Sodion compensating potassium and sodium niobate based leadless piezoelectric ceramics and method for preparing same

A potassium-sodium niobate-based, lead-free piezoelectric technology, applied in piezoelectric/electrostrictive/magnetostrictive devices, circuits, electrical components, etc., can solve the problem of lowering the sintering temperature, high lead-free piezoelectric ceramics, and See and other problems, to achieve the effect of reducing the sintering temperature

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

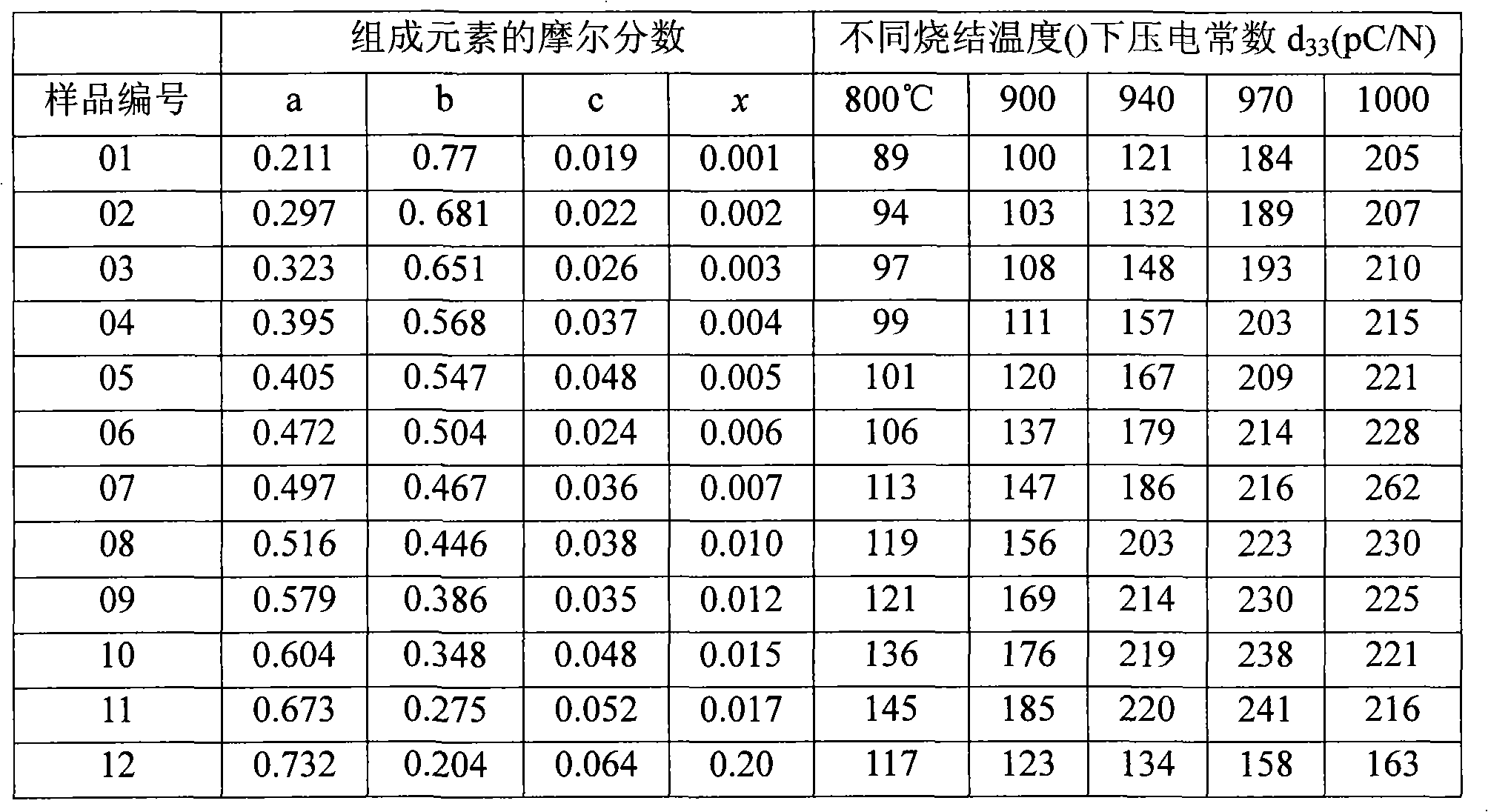

[0021] According to (Na 0.211+0.001 K 0.77 Li 0.019 )NbO 3 (x=0.001) formula, weigh 0.389gNa respectively with electronic balance 2 CO 3 , 1.812gK 2 CO 3 , 0.024gLi 2 CO 3 , and 4.533gNb 2 o 5 , using absolute ethanol as the medium, grinding and mixing the materials with a planetary ball mill for 24 hours at a speed of 250 rpm, and drying the slurry at 80° C. to obtain dry powder. The dry powder was subjected to 700°C and kept for 10 hours to synthesize niobate. Take 0.3g of powder and put it into a Φ10mm mold, and press it into shape. The formed discs were sintered in a programmed temperature-controlled box furnace, sintered at 1000° C., kept for 2 hours, and cooled to room temperature to obtain ceramic discs. After grinding with 600-mesh fine sandpaper, coat both surfaces with baked silver electrodes to make baked silver ceramic sheets, put them in silicone oil and heat to 100°C, keep at 5kV / mm voltage for 20min for polarization, and then cool down to room temper...

Embodiment 2

[0023] According to (Na 0.732+0.20 K 0.204 Li 0.064 )NbO 3 (x=0.20) formula, weigh 0.84gNa respectively with electronic balance 2 O, 0.507gK 2 CO 3 , 0.085gLi 2 CO 3 , and 4.786gNb 2 o 5 , using absolute ethanol as the medium, grinding and mixing the materials with a planetary ball mill for 3 hours at a rotation speed of 250 rpm, and drying the slurry at 80° C. to obtain dry powder. The dry powder was subjected to 750°C and kept for 7 hours to synthesize niobate. Take 0.3g of powder and put it into a Φ10mm mold, and press it into shape. The formed discs were sintered in a programmed temperature-controlled box furnace, sintered at 800° C., kept for 5 hours, and cooled to room temperature to obtain ceramic discs. After grinding with 600-mesh fine sandpaper, apply baked silver electrodes on both surfaces to make baked silver ceramic sheets, put them in silicone oil and heat to 200°C, keep at 5kV / mm voltage for 30min for polarization, and then cool down to room temperat...

Embodiment 3

[0025] According to (Na 0.516+0.01- K 0.446 Li 0.038 )NbO 3 (x=0.01) formula, weigh 1.553gNaHCO respectively with electronic balance 3 , 1.082gK 2 CO 3 , 0.049gLi 2 CO 3 , and 4.673gNb 2 o 5 , using absolute ethanol as the medium, grinding and mixing the materials with a planetary ball mill for 12 hours at a speed of 250 rpm, and drying the slurry at 80° C. to obtain dry powder. The dry powder was subjected to 850°C and kept for 5 hours to synthesize niobate. Take the powder for 0.3h, put it into a Φ10mm mold, and press to form it. The formed discs were sintered in a programmed temperature-controlled box furnace, sintered at 940° C., kept for 4 hours, and cooled to room temperature to obtain ceramic discs. After grinding with 600-mesh fine sandpaper, coat both surfaces with baked silver electrodes to make baked silver ceramic sheets, heat them in silicone oil to 140°C, keep at 4kV / mm voltage for 50min for polarization, and then cool down to room temperature to compl...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com