Polycarboxylic acids anti-freeze agent for cement concrete and method for preparing same

A technology of cement concrete and polycarboxylate, applied in the field of polycarboxylate antifreeze

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

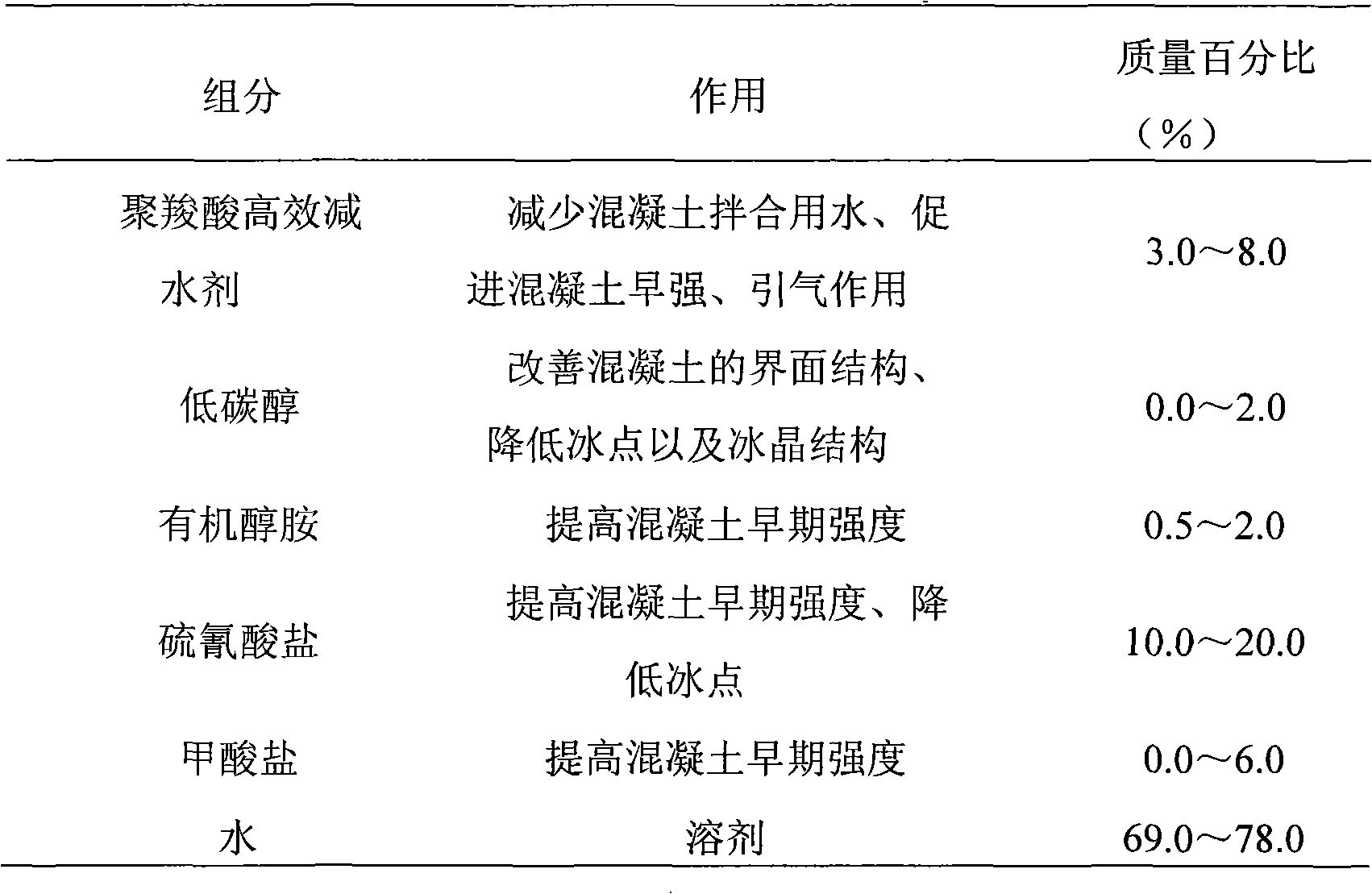

Method used

Image

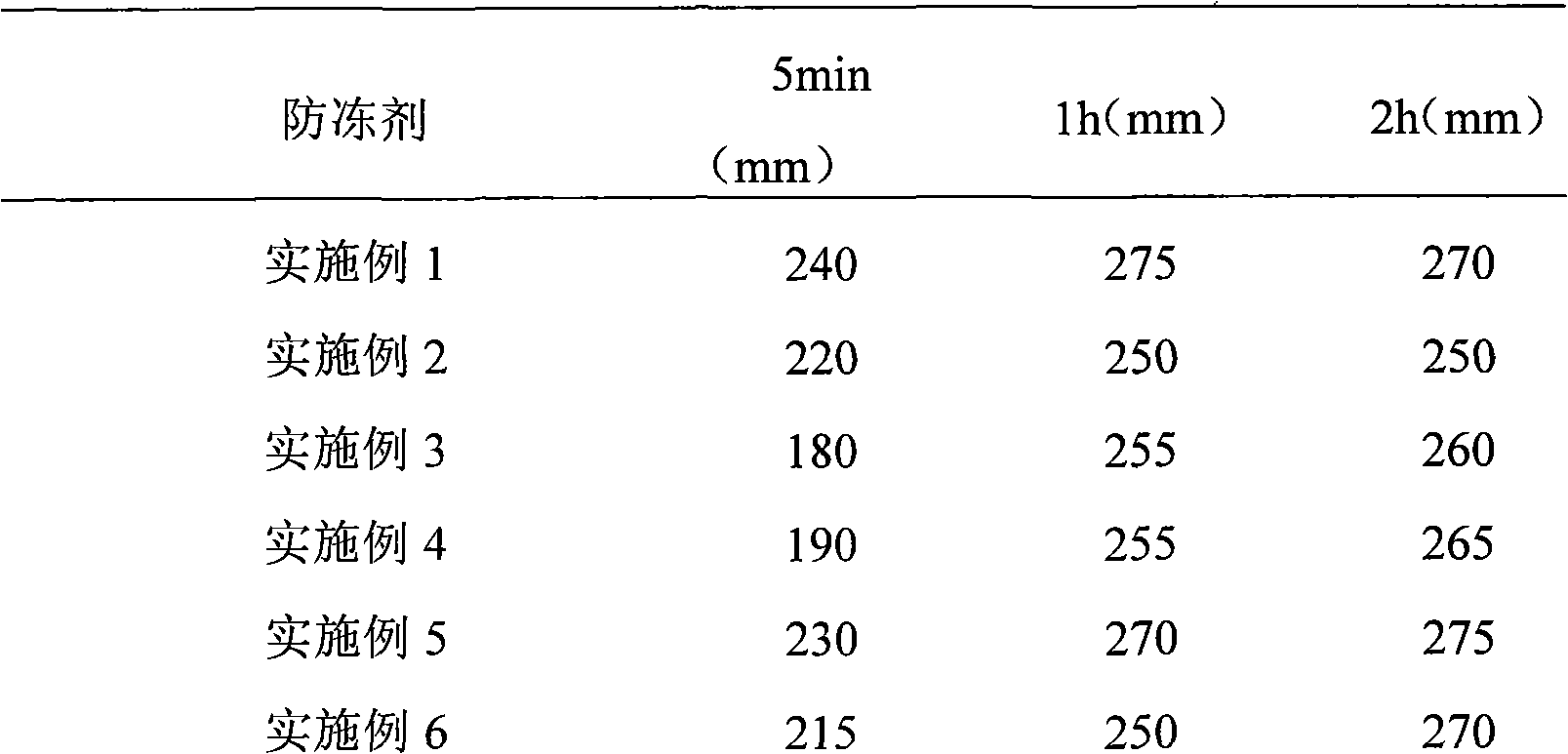

Examples

Embodiment 1

[0020] Carry out the synthesis of methacrylic polycarboxylate superplasticizer with reference to the following steps:

[0021] The first step of esterification reaction: add 80 grams of methoxypolyethylene glycol with a molecular weight of M=2000 in the reaction kettle, heat and stir, and control the temperature at 120°C, add 1.29 grams of hydroquinone as a polymerization inhibitor, and react for 15 minutes , and then 25.8 grams of methacrylic acid, 5.08 grams of p-toluenesulfonic acid, and 24.0 grams of cyclohexane were subjected to an esterification reaction; Polyethylene glycol methacrylate.

[0022]The second step of polymerization reaction: put the macromonomer obtained in the first step reaction into a four-necked flask, add 69.87 grams of water after heating and melting, heat up the water bath to 57 ° C, and add 1.47 grams of thioglycolic acid in sequence after fully stirring and dissolving. Add 7.1 grams of dilute amide and 25.92 g of an aqueous solution of 5% concent...

Embodiment 2

[0025] Carry out the synthesis of acrylic polycarboxylate superplasticizer according to the following steps:

[0026] The first step of esterification reaction: add 100 grams of methoxypolyethylene glycol with a molecular weight of M=1000 in the reaction kettle, heat and stir until fully melted, and control the temperature at 130 ° C, add 0.014 grams of hydroquinone as a polymerization inhibitor, and react After 15 minutes, 14.4 grams of acrylic acid, 1.14 grams of p-toluenesulfonic acid, and 23 grams of cyclohexane were subjected to esterification in sequence; after 4.5 hours of constant temperature reaction, the aqueous agent cyclohexane was removed by vacuuming to obtain a large single Bulk methoxypolyethylene glycol acrylate.

[0027] The second step of polymerization reaction: put the macromonomer obtained in the first step reaction into a four-necked flask, add 150.52 grams of water after heating and melting, raise the temperature to 65°C, stir and dissolve it, and then ...

Embodiment 3

[0030] According to Example 2, the acrylic polycarboxylic acid high-efficiency water reducer was synthesized, and the obtained 40.0% solution was diluted to 30.0%. Weigh 100 grams of 30.0% acrylic polycarboxylic acid superplasticizer solution and add it to a stainless steel container, then add 20 grams of triisopropanolamine and 10 grams of glycerol successively under stirring; simultaneously weigh 710ml of water and add it to the In a stainless steel container, weigh 100 grams of sodium thiocyanate and 60 grams of calcium formate, add them to the container of weighed water in turn under stirring, stir well until the solids are uniformly dissolved, then add them to the solution prepared in the first step, and stir evenly After standing still until clarified, a light yellow homogeneous liquid product with a solid content of 22.0% and a pH value of 8.2 is obtained.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com