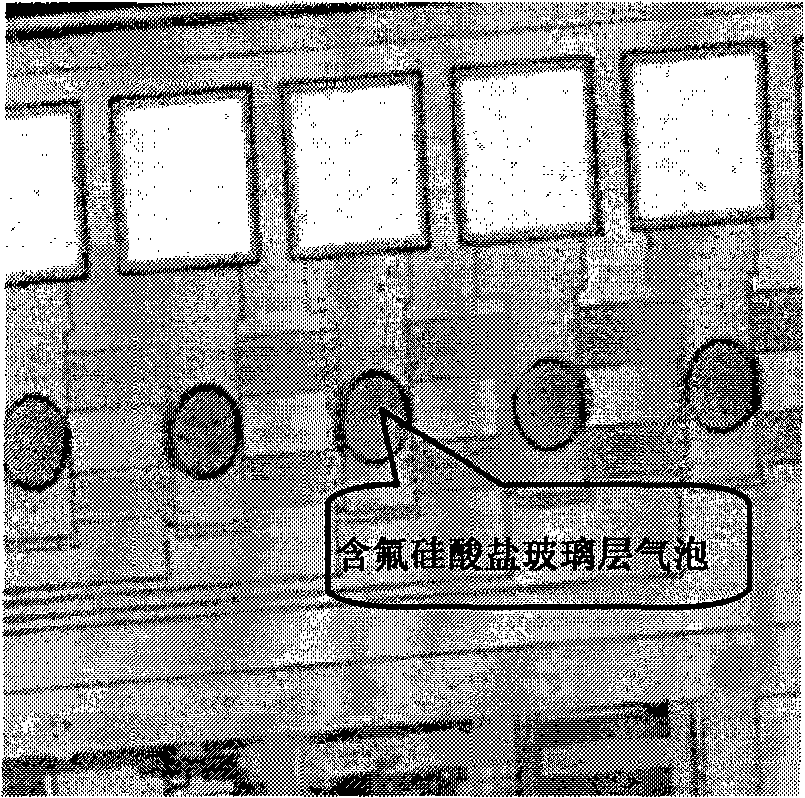

Process for effectively controlling air bubble producing in forming process of fluorine-containing silex glass interlayer medium layer

A technology of interlayer dielectric layer and silicate glass layer, applied in the direction of glass/slag layered products, layered products, metal layered products, etc., can solve the problem of interlayer dielectric layer performance damage, damage, and inability to fully function Prevent problems such as metal layer short circuit

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

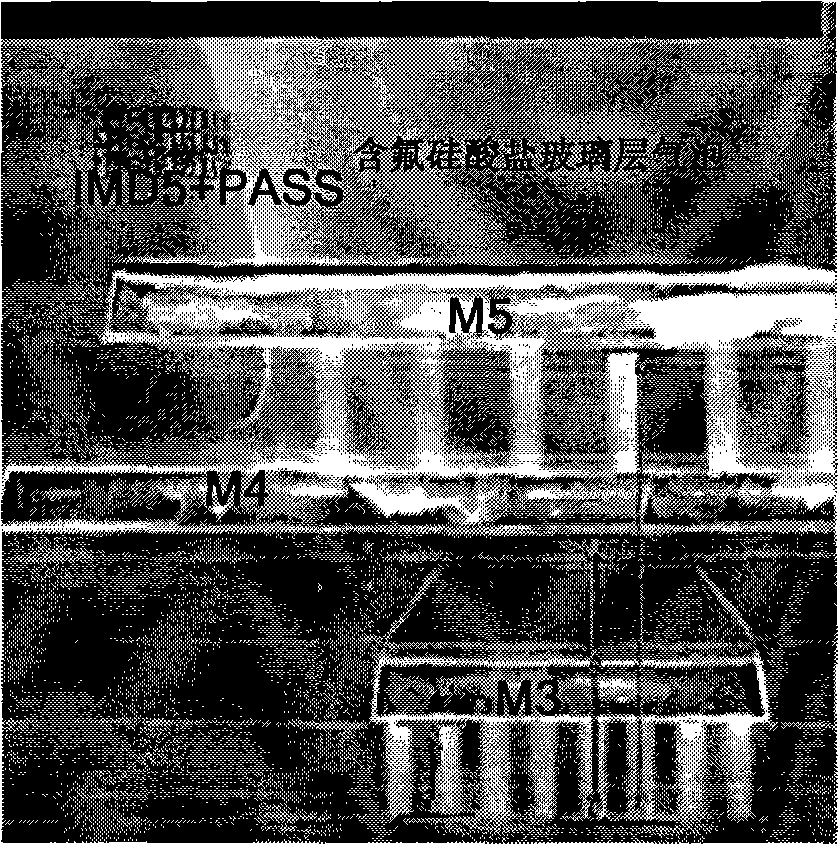

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

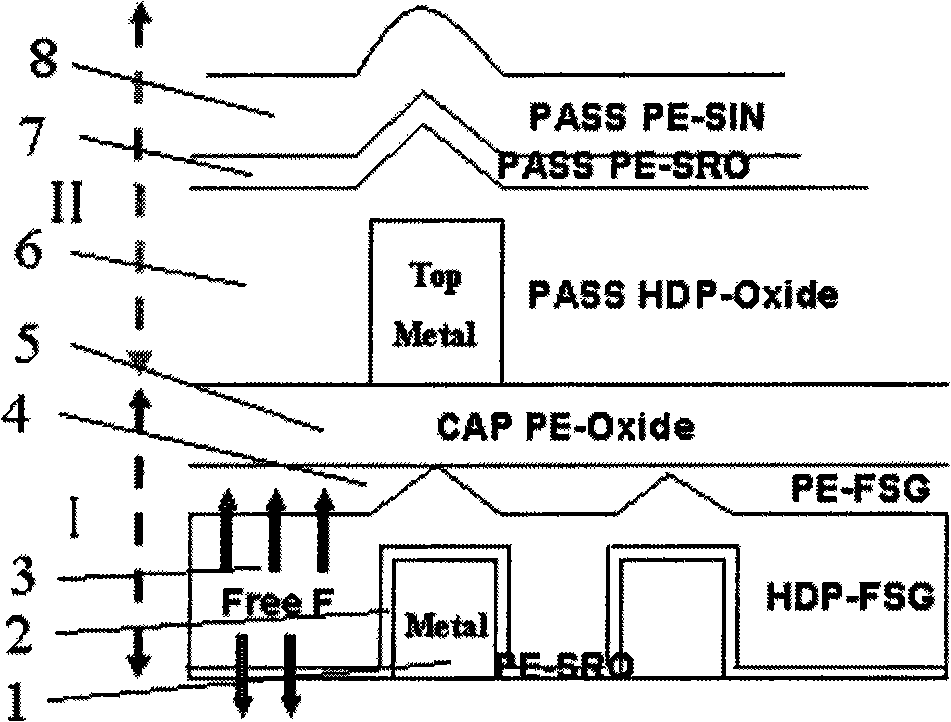

[0026] According to the method of effectively controlling the bubbles generated in the formation of the fluorine-containing silicon glass interlayer dielectric layer of the present invention, the final interlayer dielectric layer (I) with a three-layer structure and the last protective layer (II) with a three-layer structure are formed , A capacitor PE-Oxide dielectric layer is formed between the last interlayer dielectric layer (I) and the last protective layer (II), so it can prevent fluorine ions from escaping from the fluorine-containing silicon glass interlayer dielectric layer and prevent semiconductor device performance damage, which improves the product qualification rate of semiconductor devices. Such as image 3 Displayed, in order from bottom to top, includes:

[0027] Step 1, before forming the final fluorine-containing silicate glass interlayer dielectric layer on the metal layer (1), first form PE-SRO (plasma-enhanced silicon-rich silicon glass) with high dielec...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com