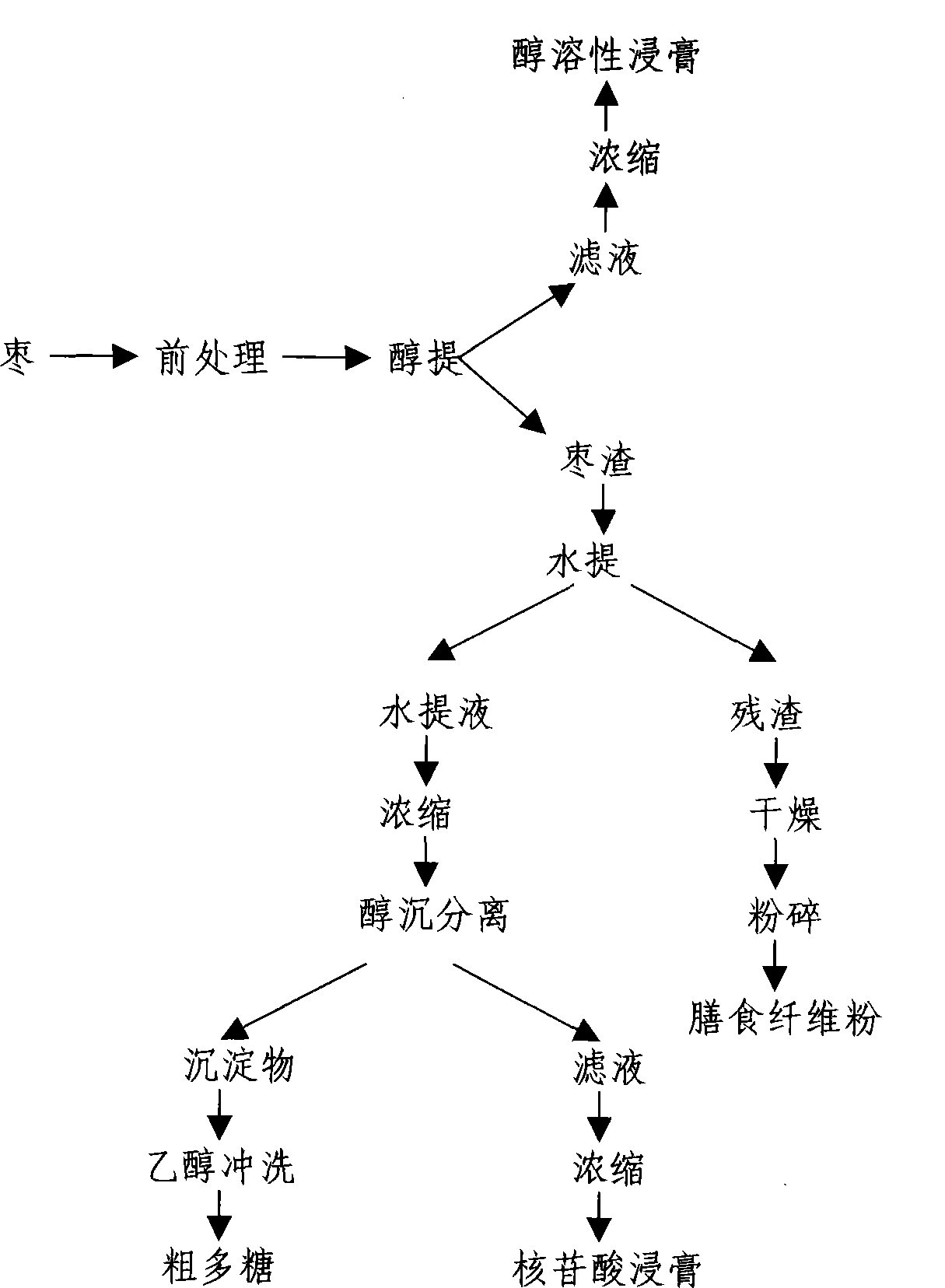

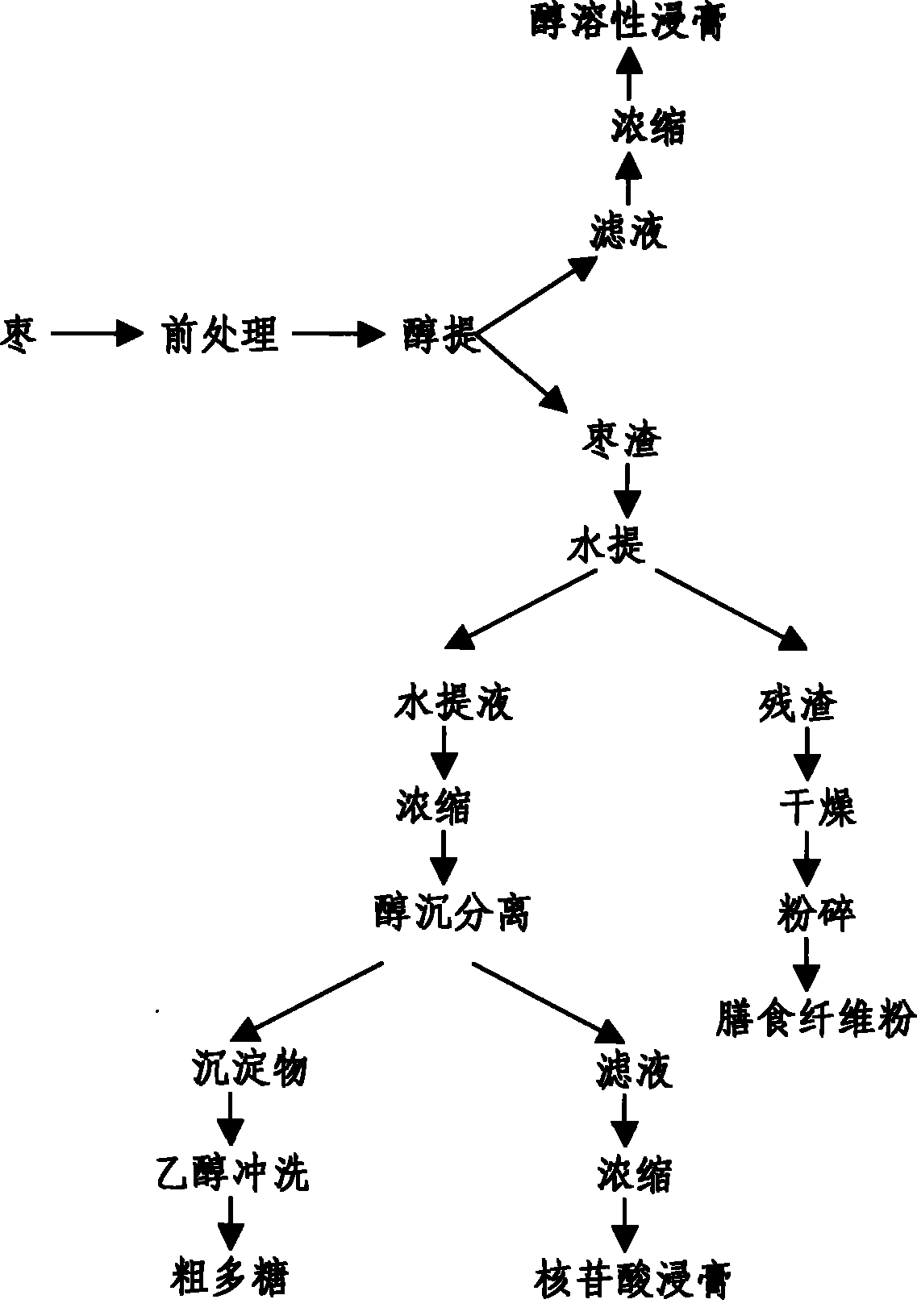

Method of sequential extraction of biological activity component from jujube

A bioactive ingredient and graded extraction technology is applied in the field of extracting a variety of bioactive ingredients from jujube, which can solve the problems of not being able to make the best use of jujube resources and pollution of organic solutions, and achieve the effects of low cost and simple operation.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0023] Remove the inedible parts such as pests and diseases from the mature jujube fruits, wash them with running tap water, and manually remove the pits. Weigh 1Kg jujube fruit and place it in a blast drying oven, and dry it at 60-65°C for 10 hours until the moisture content is about 10%. The dried jujube fruit is taken out, after cooling, mechanically crushed into 10-mesh granules.

[0024] Add 10L of 65% ethanol to the jujube fruit granules, and extract them with an ultrasonic wave with a frequency of 25KHz and a power of 200W for 40min at 50°C, repeat the extraction twice, and stand to separate. The filtrates were combined, concentrated under reduced pressure at 60°C and 0.08 MPa, and ethanol was recovered to obtain 460 g of alcohol-soluble extract, the main component of which was jujube flavonoids.

[0025] 10L of deionized water was added to the jujube dregs obtained after alcohol extraction to adjust the pH of the solution to 7. The conventional water bath method was u...

Embodiment 2

[0031] Remove the inedible parts such as pests and diseases from the mature jujube fruits, wash them with running tap water, and manually remove the pits. Weigh 500g jujube fruit and place it in a blast drying oven, and dry it at 60-65°C for 10h until the water content is about 10%. The dried jujube fruit is taken out, after cooling, mechanically crushed into 20-mesh granules.

[0032] Add 6L of 70% ethanol to the jujube granules, extract with a microwave frequency of 40MHz and power of 500W for 30min at 60°C, repeat the extraction twice, and stand for separation. The filtrates were combined, concentrated under reduced pressure at 63°C and 0.09 MPa, and ethanol was recovered to obtain 238 g of alcohol-soluble extract, the main component of which was jujube flavonoids.

[0033] Add 4.5L of deionized water to the jujube dregs obtained after alcohol extraction, adjust the pH of the solution to 5, and extract with a conventional water bath method, the extraction temperature is 50...

Embodiment 3

[0039] Remove the inedible parts such as corrosion by diseases and insect pests from the mature jujube fruit, wash them with running tap water, and remove the cores by an automatic pitting machine. Weigh 1 kg of jujube fruit and place it in a blast drying oven, and dry it at 60-65°C for 12 hours until the water content is about 8%. The dried jujube fruit is taken out, after cooling, mechanically crushed into 40-mesh granules.

[0040] Add 10L of 70% ethanol to the jujube granules, and extract in a water bath at 60°C for 2 hours. Repeat the extraction 3 times and let stand to separate. Combine the filtrates, concentrate under reduced pressure at 58°C and 0.07 MPa, and recover ethanol to obtain 505 g of alcohol-soluble extract, the main component of which is jujube flavonoids.

[0041]Add 9.2L of deionized water to the jujube dregs obtained after alcohol extraction, adjust the pH of the solution to 11, use microwave extraction, frequency 50MHz, power 800W, temperature 50°C, ti...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com