Coal-burning boiler system mixing modeling method

A coal-fired boiler and hybrid modeling technology, applied in the information field, can solve the problems of high energy consumption, poor control performance, and low model accuracy.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0034] The specific embodiments of the present invention will be described in detail below in conjunction with the technical solutions.

[0035] Take the process modeling of circulating fluidized bed boiler system as an example:

[0036] Here, the modeling of the steam temperature loop of the system is described as an example. The steam temperature is not only affected by the amount of desuperheating water in the desuperheater, but also by the fuel flow, air flow and steam flow. The adjustment method adopts the amount of desuperheating water, and the rest of the effects are regarded as uncertain factors.

[0037] (1) Establish a local prediction model for the steam temperature of the coal-fired boiler system.

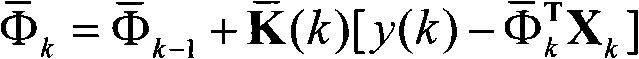

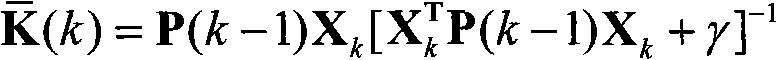

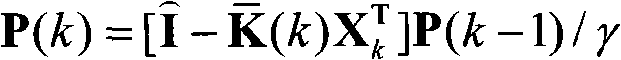

[0038] The real-time process steam temperature operation data is collected by the data acquisition device, and the collected real-time process steam temperature operation data is used as a data-driven sample set, and the least squares method is used to reason, and the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com