Tooth thickness variable cylinder profile modified gear and gearing device using same

A technology of shifting gears and transmission devices, applied in the directions of gear transmission devices, transmission devices, hoisting devices, etc., can solve the problems such as the inability to completely solve the problem of gear transmission backlash, complex structure and assembly, and troublesome precision machining. The effect of strength, simple structure and low cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

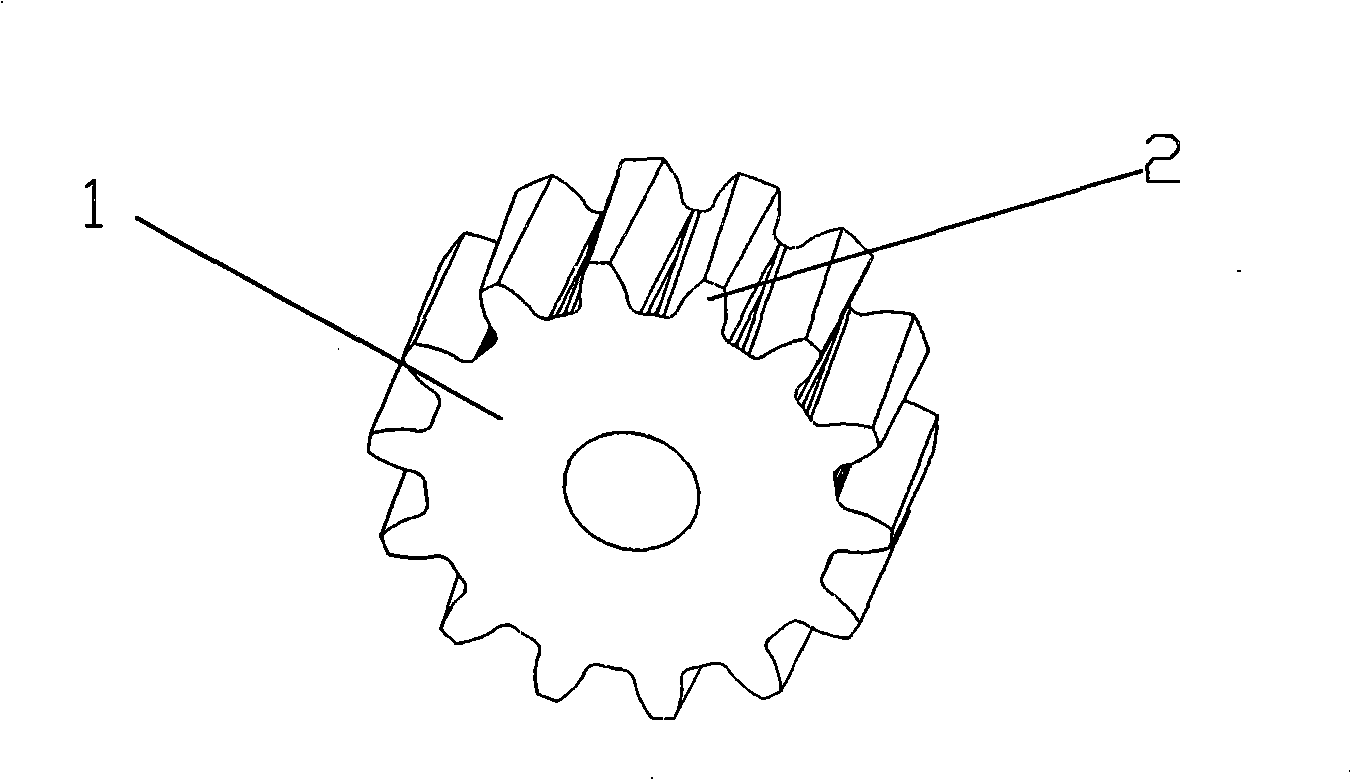

[0021] figure 1 It is a schematic diagram of the displacement gear structure of the present invention, as shown in the figure: the variable tooth thickness cylindrical displacement gear of this embodiment includes gear plate 1 and gear teeth 2, the gear adopts the form of tangential displacement, and the tangential displacement coefficient Along the axis of the gear plate 1, it changes linearly according to the law from small to large, and the tangential displacement coefficient of the two tooth surfaces of the gear tooth 2 is in the same direction from small to large, so that the two tooth surfaces of the gear teeth form a certain angle; Gear 2 also adopts the form of radial displacement, and the radial displacement coefficient is a constant value; during processing, radial displacement processing is first performed to the designed tooth thickness, and then tangential displacement processing is performed.

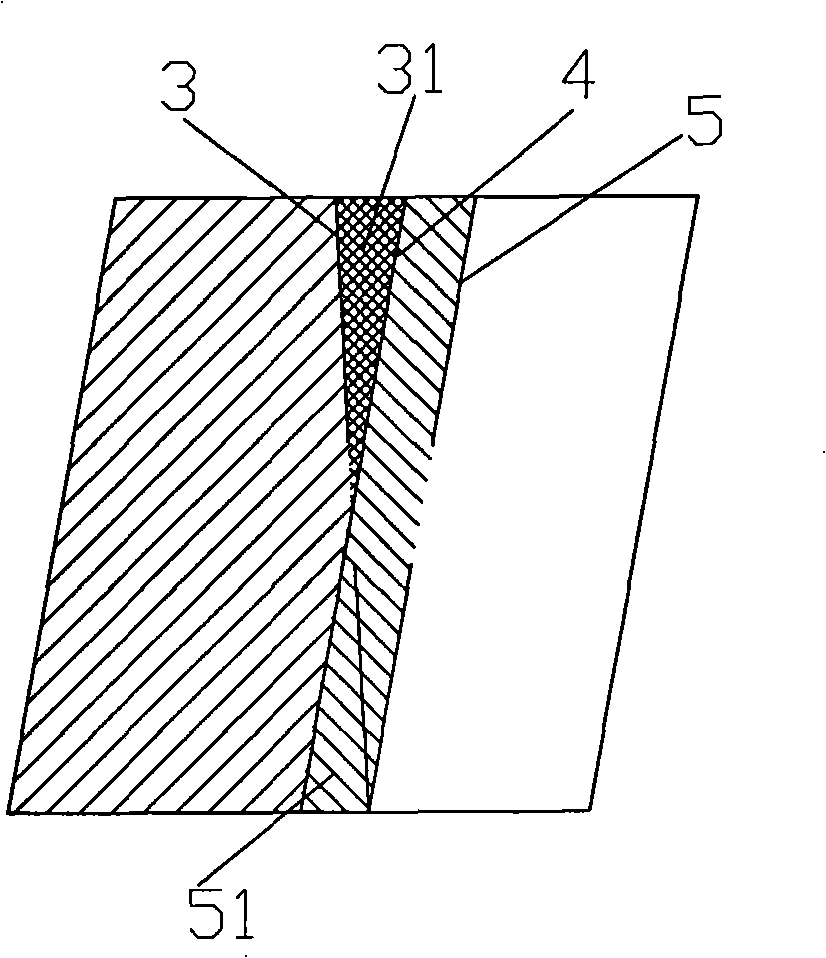

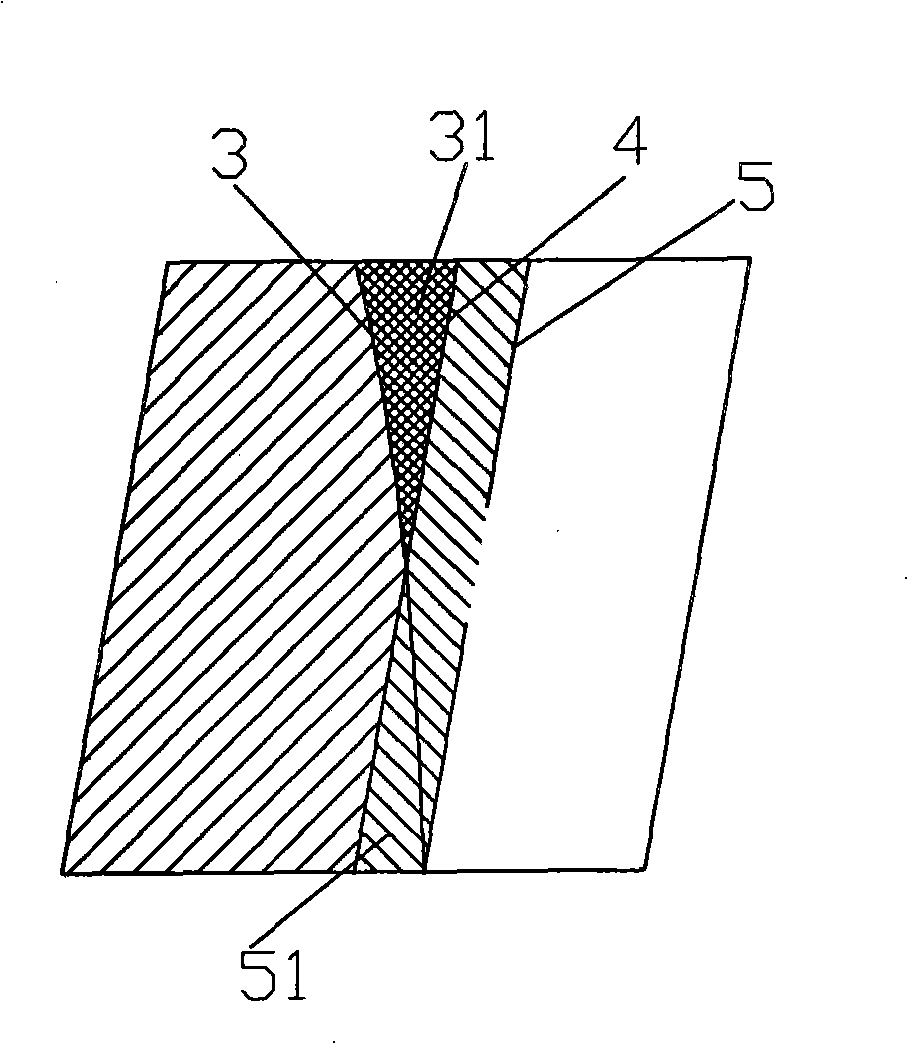

[0022] figure 2 It is the expansion diagram of the shifted gear alo...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com