Industrialized culture method and device for photosynthetic autotroph

A photosynthetic auto-oxygen and microorganism technology, applied in microorganism-based methods, biochemical cleaning devices, biochemical equipment and methods, etc., can solve the problem of not having the carbon capture function of industrial waste gas, difficult to maintain species, and the need for cultivation area. It can achieve the effect of restoring the ecological function of fishery, integrating the cost of energy output, and reducing the cost of comprehensive engineering.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

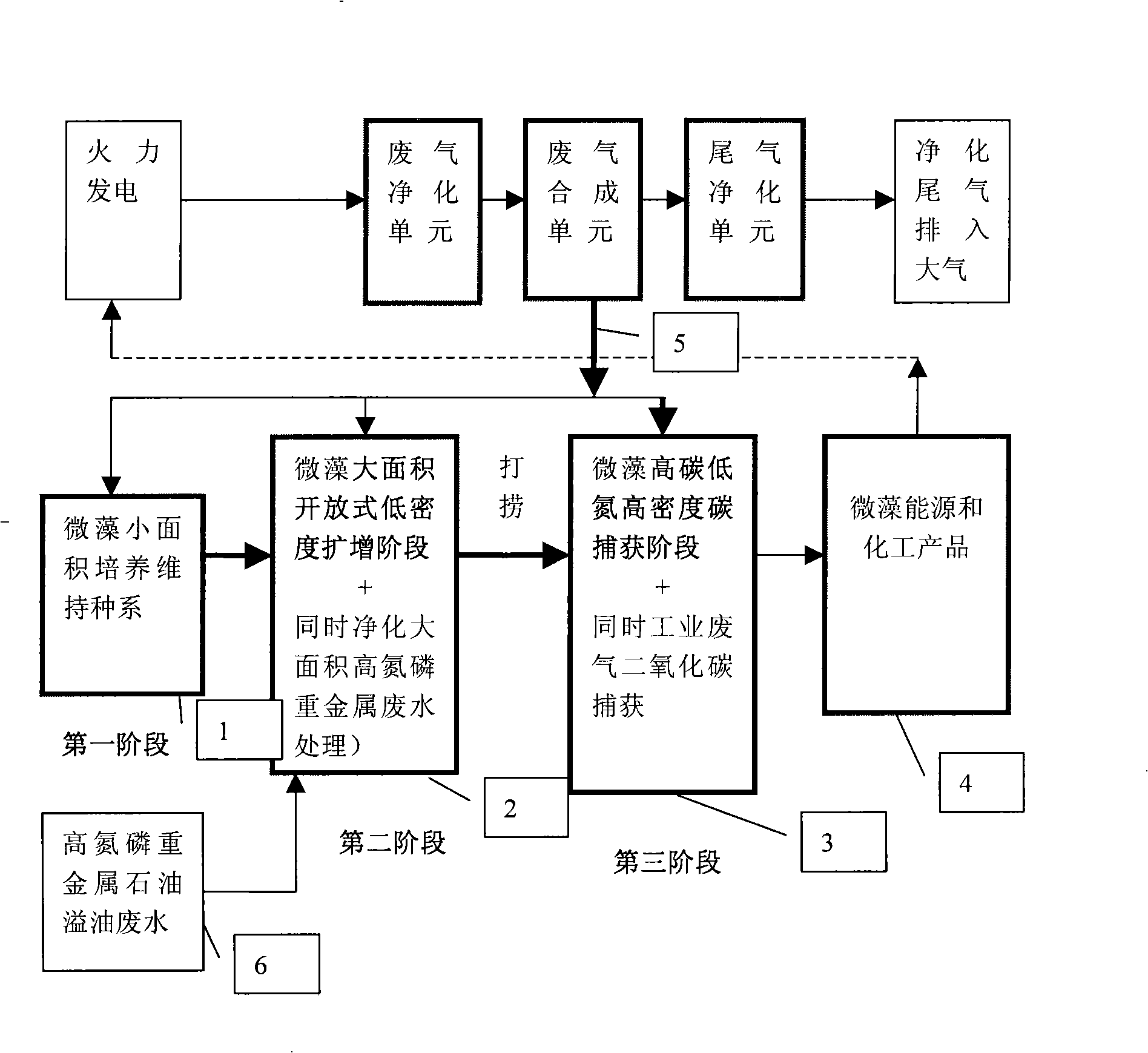

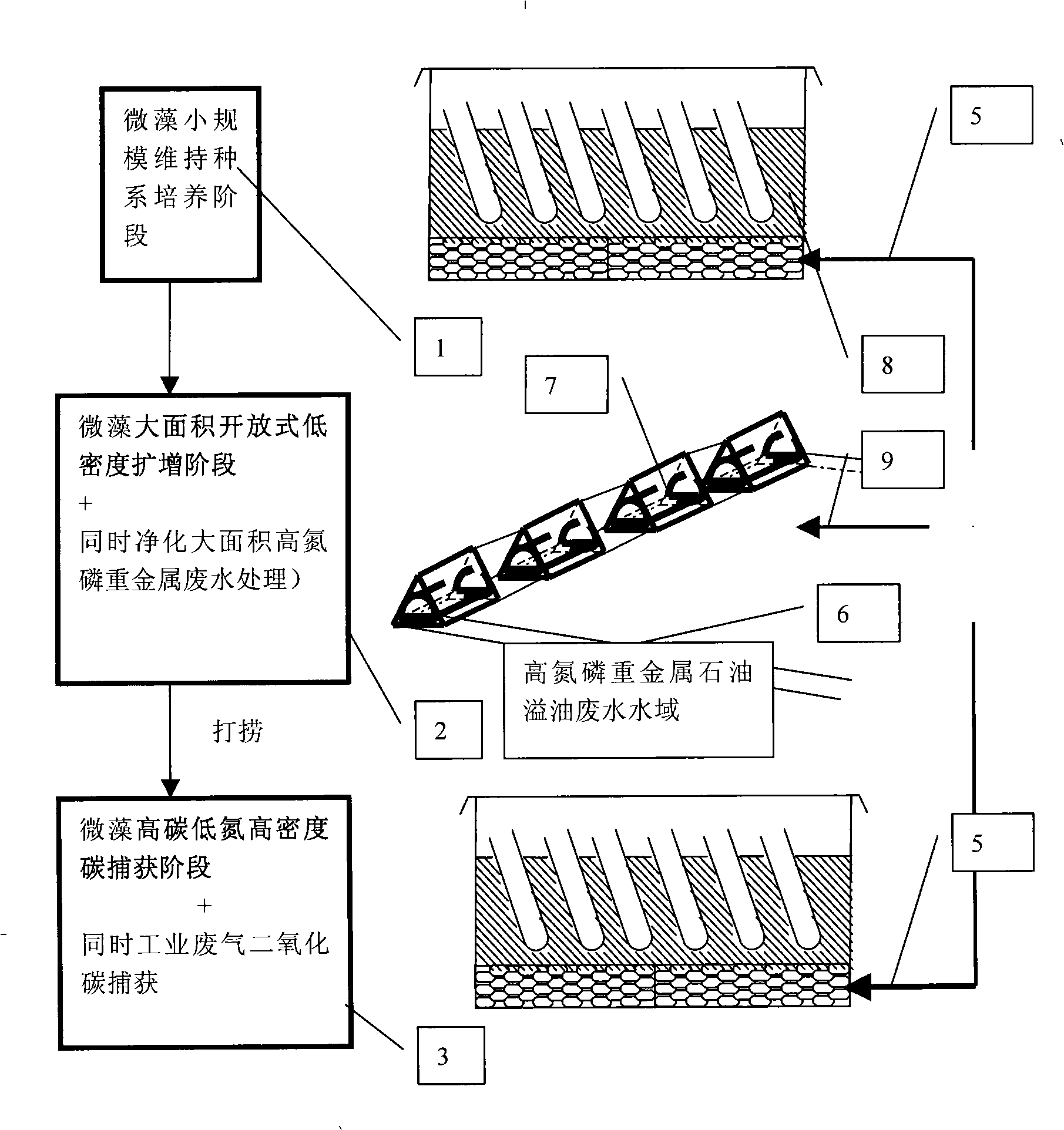

[0040] see figure 2 , the industrialized cultivation of photosynthetic aerobic organisms, especially microalgae, is divided into three stages and integrates biomass energy production, industrial waste gas carbon dioxide capture, and large-area high-nitrogen, phosphorus, and heavy metal oil spill wastewater treatment as one example. The cultivation was divided into three stages: "Small-area Germline Maintenance Stage 1", "Large-area Open Expansion Stage 2" and "High Carbon and Low Nitrogen Carbon Capture Stage 3". "Small-area germline maintenance stage" uses small-area high-nitrogen and high-density culture to prevent pollution and is used to maintain microalgae germlines. The incubator is designed to combine three-dimensional culture to increase the yield per unit area. After harvesting, the microalgae are put into the "large-area open expansion stage 2", and the open low-density culture is carried out in the eutrophic high-nitrogen and phosphorus heavy metal oil spill sewage...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com