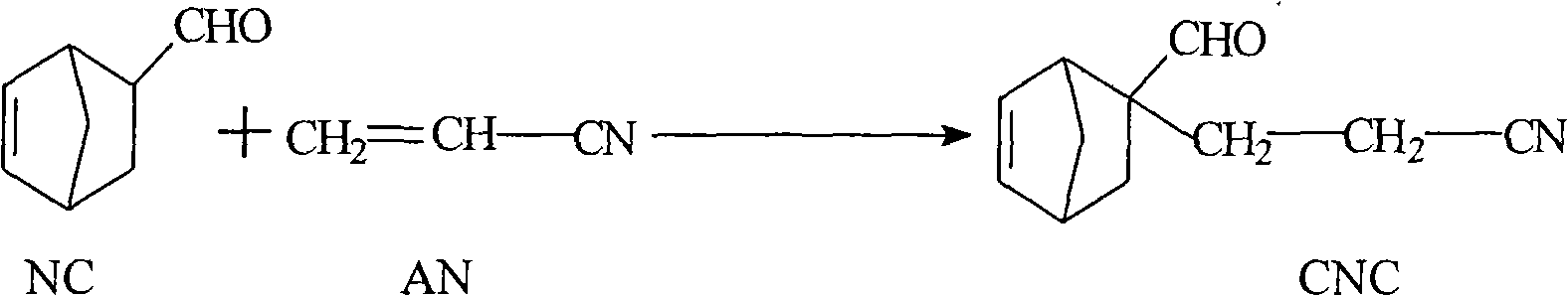

Production process of CNC

A production process and process technology, applied in the field of [2, can solve the problems of difficult impurity removal, long production cycle, no more effective detection technology for CNC quality, etc., to achieve the effect of shortening the holding time, shortening the production cycle, and shortening the holding time.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

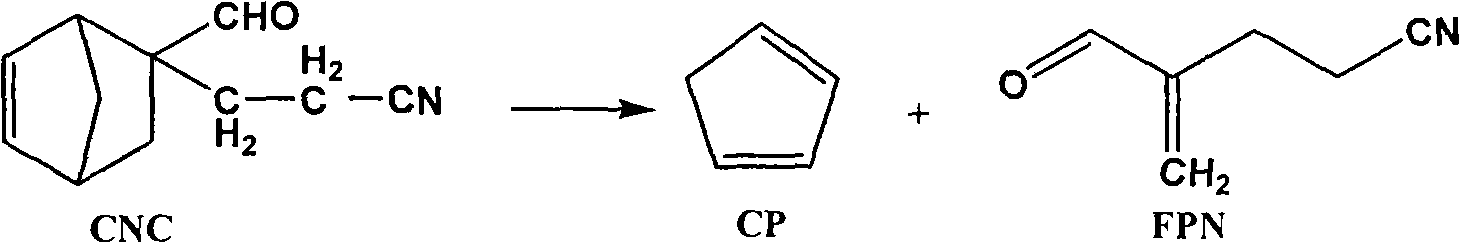

Method used

Image

Examples

Embodiment 1

[0015] In the dry 5000L reactor, drop 3500Kg of qualified toluene (content ≥ 90%, moisture ≤ 0.02%) into the dry 5000L reactor, pass nitrogen, start stirring, drop into 22Kg of anhydrous tert-butanol, 18Kg of KOH successively, and wait for the temperature of toluene to reach Put 470Kg AN at 25°C, start to add NC (605Kg) dropwise at 30°C, the dropwise addition time is 3 hours and 5 minutes, the temperature is controlled at 30°C, and keep warm for 1.5 hours after the dropwise addition, to obtain a brownish-red transparent liquid, take a sample The gas chromatography peak of NC was measured at 0.2% (external standard method, 2m stainless steel 5% OV-255 column, column temperature 120°C-140°C, vaporization 170°C-190°C, detection 200°C, the same below), suction filtration and washing , precipitation, get 1012Kg CNC, get 500Kg CNC and drop into cracking in the still, get the FPN of 192Kg (content is 95.6%).

Embodiment 2

[0017] Put 3403Kg of treated toluene (content ≥ 90%, moisture ≤ 0.02%) into the dry reactor, pass nitrogen, start stirring, and then add 21.6Kg of anhydrous tert-butanol, 21.6Kg of KOH, and wait for the toluene temperature Put 473Kg AN at 26°C, start to add NC (600Kg) dropwise at 31°C, the dropwise addition time is 3 hours, the temperature is controlled at 31°C, and keep warm for 1 hour after the dropwise addition, to obtain a brownish-red transparent liquid, which is sampled and tested. Obtain NC peak 0.3%, suction filtration, washing, precipitation, obtain 1006Kg CNC, get 450Kg CNC and put into the pyrolysis still, obtain the FPN of 176Kg (content is 95.1%).

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com