Method for rolling and shaping nickel-based high-temperature alloy special-shaped ring forging

A technology of nickel-based superalloy and special-shaped ring, applied in metal rolling and other directions, can solve the problems of prolonged production cycle, coarse grains of ring forgings, undisclosed process steps of rolling nickel-based superalloy special-shaped ring forgings, etc. Excellent, uniform texture

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach

[0026] The main chemical element content (percentage by weight) of the alloy is: 17.0% to 21.0% of Cr, 50.0% to 55.0% of Ni, 2.80% to 3.30% of Mo, 0.75% to 1.15% of Ti, 0.75% to 1.15% of Ti, The amount of Al is 0.30%-0.70%, the content of C is ≤0.08%, the content of Co is ≤1.0%, and other trace elements are also contained, and the balance is Fe.

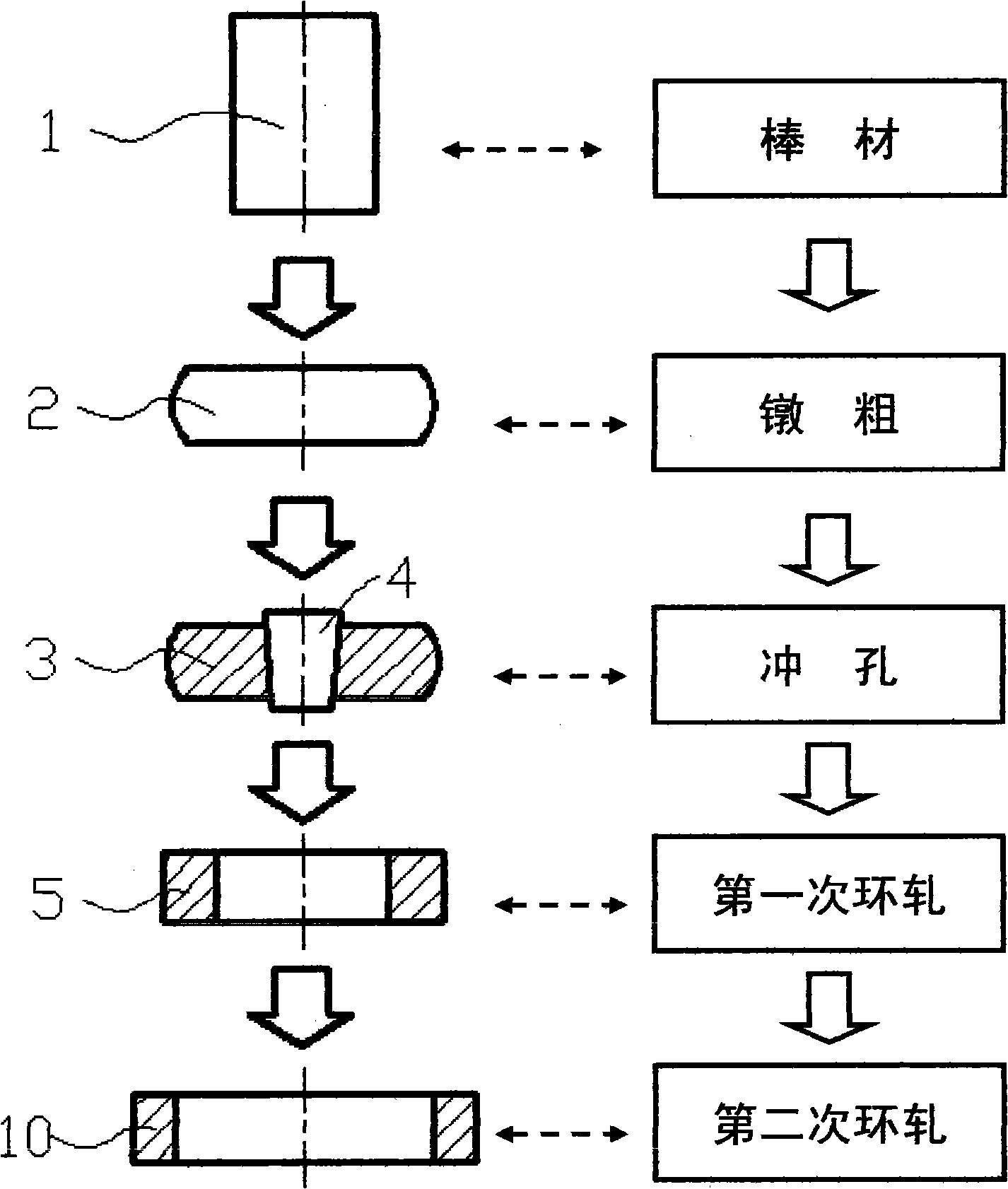

[0027] The process steps of the alloy from the bar to the production of qualified special-shaped ring forgings are as follows:

[0028] Step 1: Billet making of a rectangular pre-rolled billet. like figure 1 As shown, the GH4169 alloy rod 1 blanked according to the specification is heated to a deformation temperature of 1000°C to 1050°C in a forging heating furnace, upsetting on a forging press to deform 60% to 65% to obtain a solid round cake 2, and then Punch the solid round cake 2 out of the central hole with a punch 4 to obtain a hollow round cake 3, the inner diameter of the hollow round cake 3 is 30% to 35% of its outer diame...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com