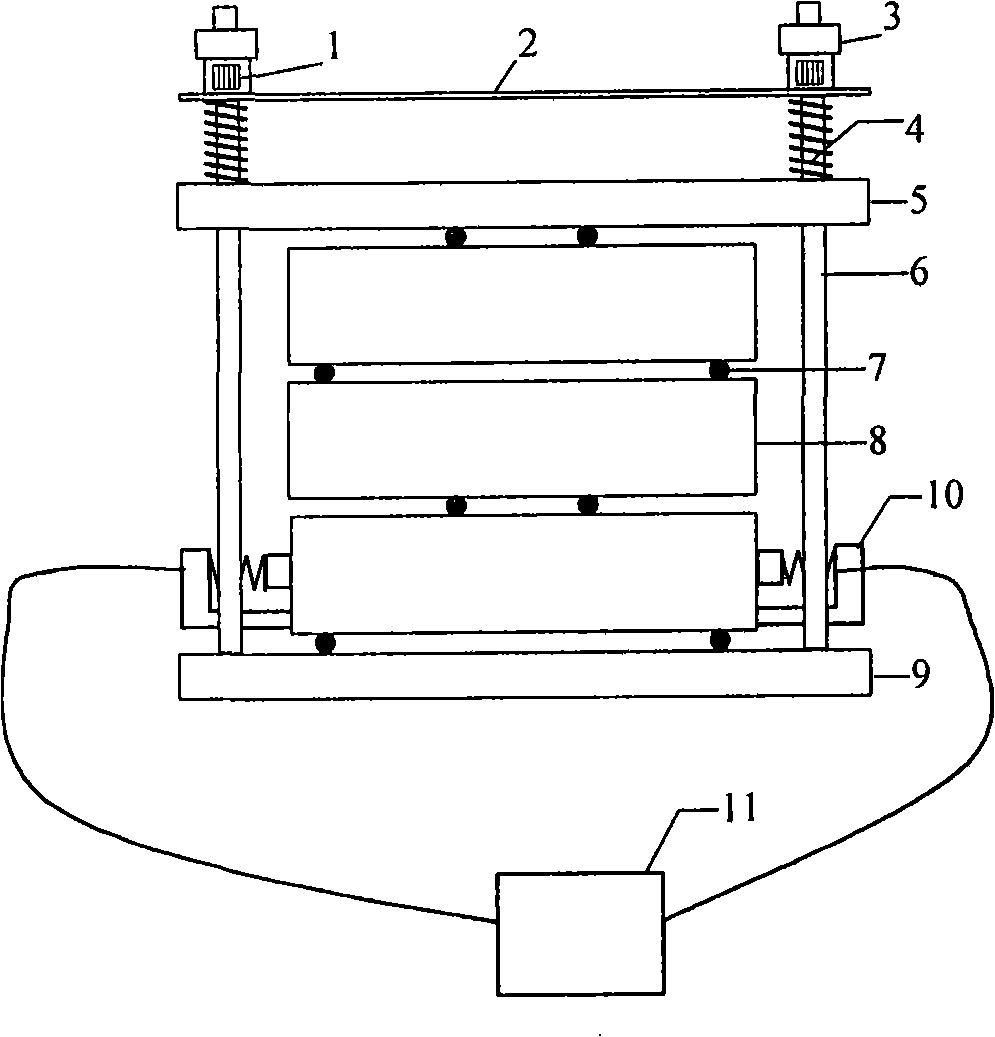

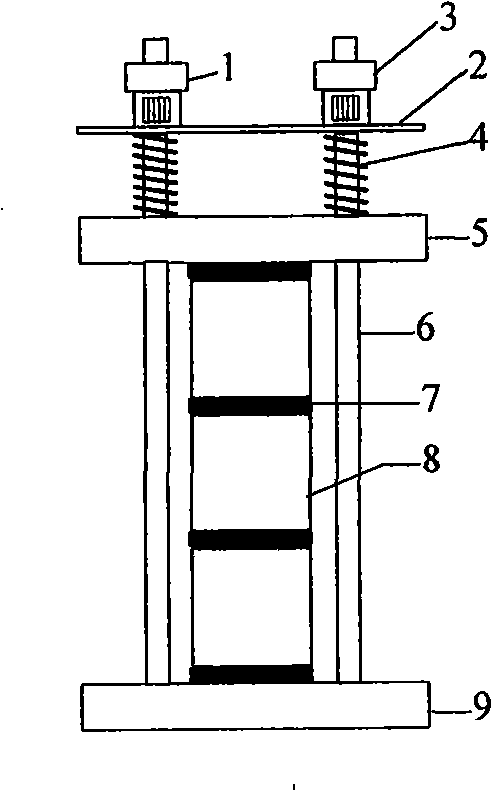

Concrete multi-factors durability experimental device under bent tension stress and environment coupled action

An experimental device and concrete technology, applied in the direction of applying a stable bending force to test the strength of materials, material inspection products, etc., can solve the problems of low control precision of stress wrench, change of bolt friction coefficient, occupying test space, etc., and achieve accurate test results Reliable, uniform and accurate force, and simple force application method

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

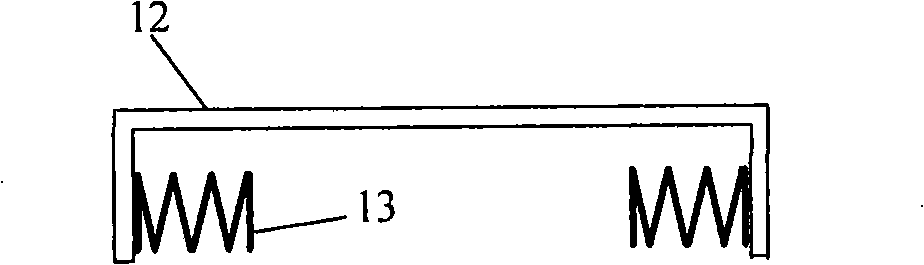

Method used

Image

Examples

Embodiment 1

[0037] Concrete mix ratio (kg / m 3 ): cement-275, fly ash-183, sand-705, gravel-1127, water-160, polycarboxylate superplasticizer-3.2

[0038] According to the above ratio, use a forced mixer to mix well, pour the freshly mixed concrete into a steel mold with a size of 70mm×70mm×280mm, vibrate on a vibrating table for 30s, and demould after standing in the laboratory for 24 hours, and then pour the concrete specimen Put it into a standard curing room (temperature (20±3°C, relative humidity above 90%)) to cure to the specified age and then take it out. Use the MTS810 experimental machine to perform a four-point bending strength test on the cured concrete specimen, and pass the control during the experiment. The loading rate is 0.01mm / s. During the four-point bending test, the center span of the lower bottom surface is 210mm, and the span of the fulcrum of the upper surface is 70mm. According to the measured bending strength, 0.20, 0.35, 0.50, 0.65, 0.80 six A stress level (bend...

Embodiment 2

[0040] Concrete mix ratio (kg / m 3 ): cement-275, fly ash-183, sand-705, gravel-1127, water-160, polycarboxylate superplasticizer-3.2

[0041] According to the above ratio, use a forced mixer to mix well, pour the freshly mixed concrete into a steel mold with a size of 70mm×70mm×280mm, vibrate on a vibrating table for 30s, and demould after standing in the laboratory for 24 hours, and then pour the concrete specimen Put it into a standard curing room (temperature (20±3°C, relative humidity above 90%)) to cure to the specified age and then take it out. Use the MTS810 experimental machine to perform a four-point bending strength test on the cured concrete specimen, and pass the control during the experiment. The loading rate is 0.01mm / s. During the four-point bending test, the center span of the lower bottom surface is 210mm, and the span of the fulcrum of the upper surface is 70mm. According to the measured bending strength, 0.20, 0.35, 0.50, 0.65, 0.80 six A stress level (bend...

Embodiment 3

[0043] Concrete mix ratio (kg / m 3 ): cement-275, fly ash-183, sand-705, gravel-1127, water-160, polycarboxylate superplasticizer-3.2

[0044] According to the above ratio, use a forced mixer to mix well, pour the freshly mixed concrete into a steel mold with a size of 70mm×70mm×280mm, vibrate on a vibrating table for 30s, and demould after standing in the laboratory for 24 hours, and then pour the concrete specimen Put it into a standard curing room (temperature (20±3°C, relative humidity above 90%)) to cure to the specified age and then take it out. Use the MTS810 experimental machine to perform a four-point bending strength test on the cured concrete specimen, and pass the control during the experiment. The loading rate is 0.01mm / s. During the four-point bending test, the center span of the lower bottom surface is 210mm, and the span of the fulcrum of the upper surface is 70mm. According to the measured bending strength, 0.20, 0.35, 0.50, 0.65, 0.80 six A stress level (bend...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com