Low water temperature high-efficiency heat exchange tube full solution type evaporator

A flooded evaporator and heat exchange tube technology, which is applied in the field of evaporators, can solve the problems of difficulty in improving heat exchange efficiency, restricting the utilization of low-temperature water sources, and low ribbing coefficient of heat exchange tubes, so as to improve heat exchange efficiency and improve Heat exchange efficiency, uniform distribution effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0016] The specific embodiment of the present invention will be described with reference to the accompanying drawings.

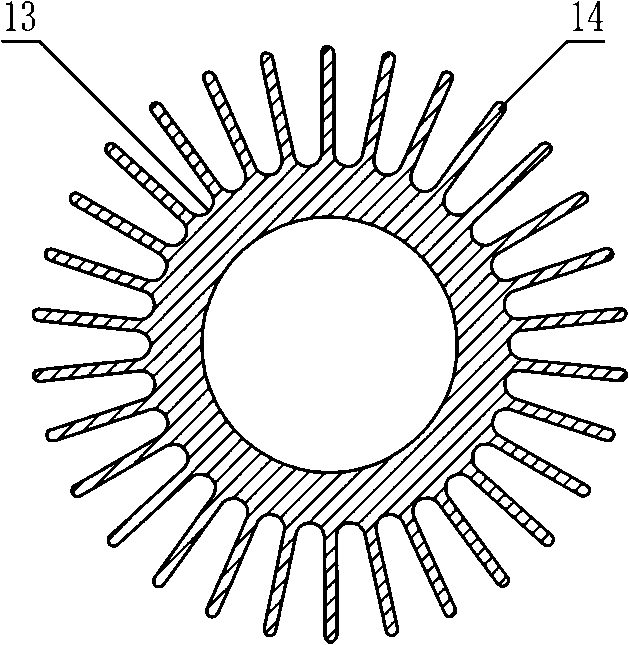

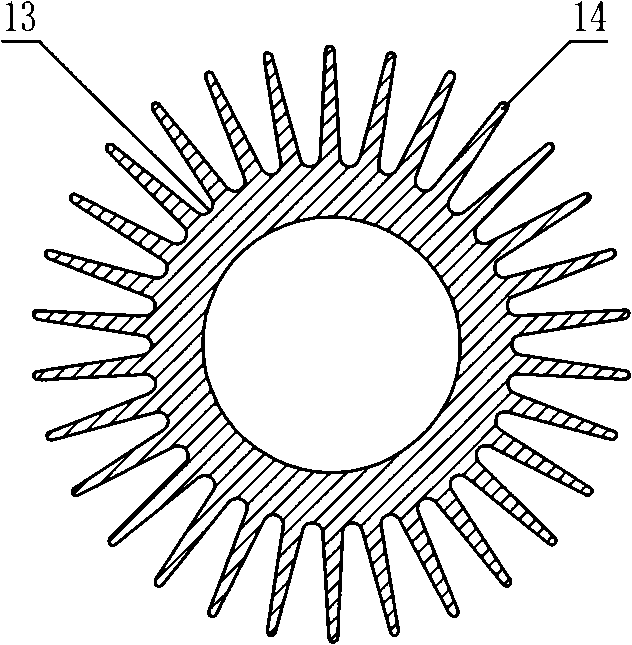

[0017] as attached figure 1 , the low water temperature high-efficiency heat exchange tube flooded evaporator includes an outer casing 5 configured with a water inlet 1, a water outlet 2, a refrigerant liquid inlet 3, and a gas outlet 4. The heat exchange tubes 7 are horizontally and fixedly assembled in the outer casing in the form of straight tubes and single water passes, and the outer casing is divided into a water inlet chamber and an outlet chamber connected through the heat exchange tube bundle, and a refrigerant liquid storage chamber placed between the two tube sheets. An oil return port 8 and a liquid level controller 9 are installed on the outer casing corresponding to the liquid level of the refrigerant in the storage chamber. A gas-liquid heat exchanger 11 composed of a tube-side cavity through which refrigerant liquid passes and a shell-side c...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com