Furnace for converting and casting oxygen-free copper ingot

An oxygen-free copper and casting furnace technology, which is applied in the direction of furnace, electric furnace heating, furnace components, etc., can solve the problems of non-reduction, etc., and achieve the effect of low cost, convenient operation and simple structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

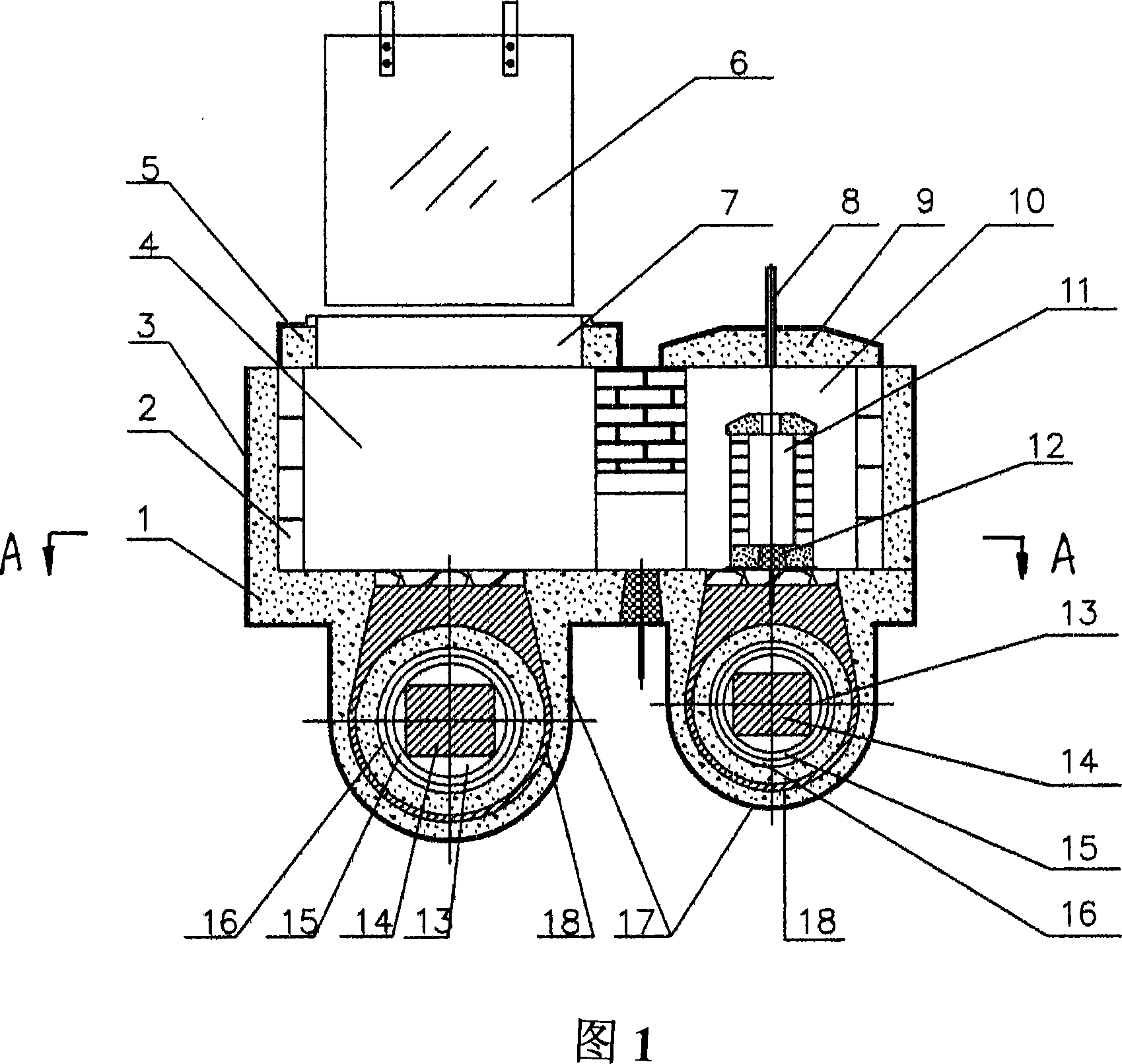

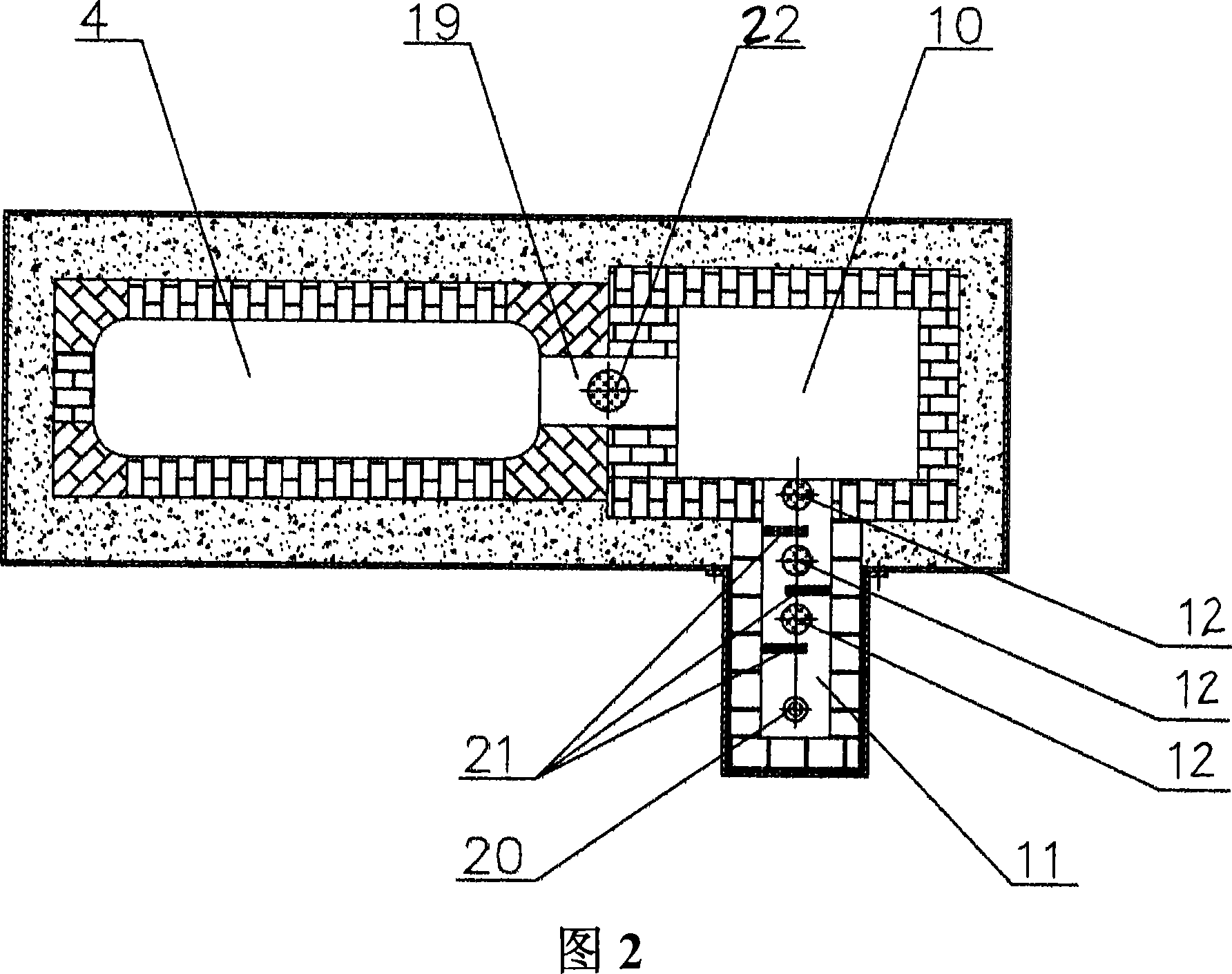

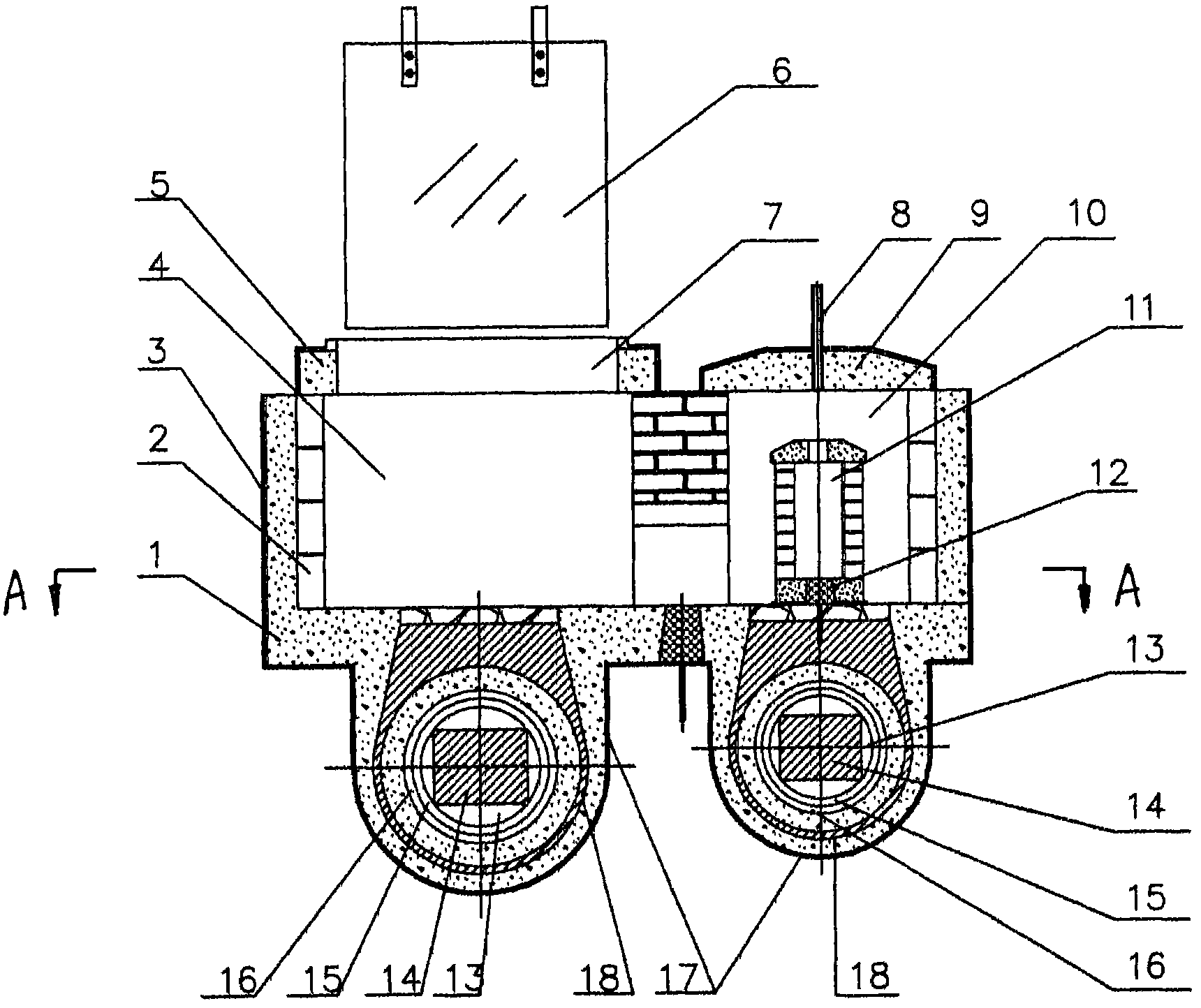

[0013] The present invention mainly consists of a furnace shell 3 with refractory bricks 1 and refractory materials 2, a smelting furnace 4 and a deoxidation furnace 10 with an electric induction heater 17 arranged side by side in the furnace shell 3, and a smelting furnace 4 and a deoxidation furnace 10. The bottom blowing launder 19 with air-permeable bricks 22 at the bottom is connected to the deoxidation furnace 10, and the bottom blowing furnace head 11 with the casting port 20 and bottom blowing bricks 12 at the bottom is placed in the bottom blowing furnace head 11 in an "S" shape. The diversion tank 21 is composed of the melting furnace cover 5 placed on the upper part of the melting furnace 4, the deoxidizing furnace cover 9 with the exhaust port 8 placed on the upper part of the deoxidizing furnace 10, and the like. The electric induction heater 17 is composed of an iron core 14 and a coil 15 placed in the furnace bottom chamber 13, a melting channel 18 surrounding th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com