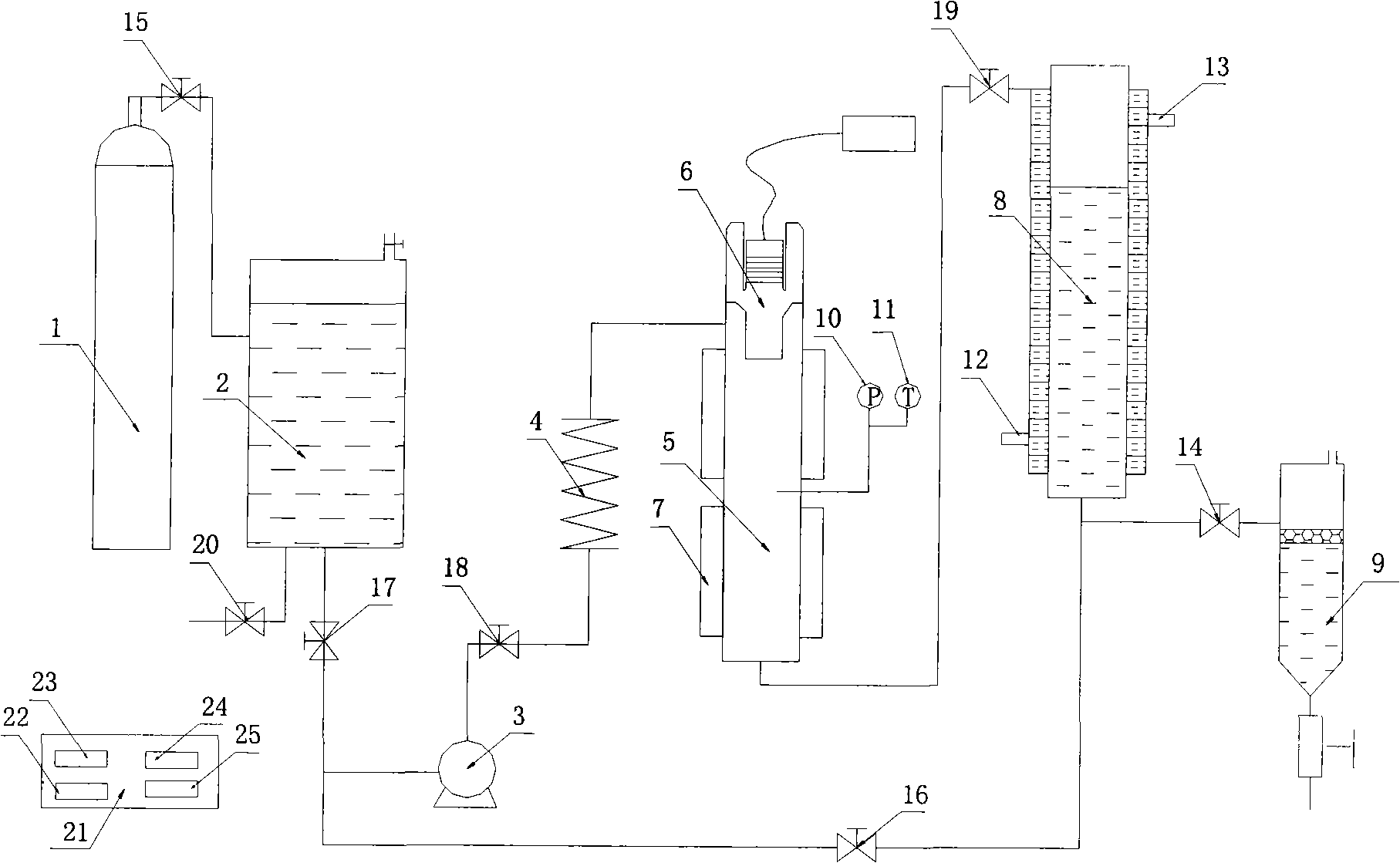

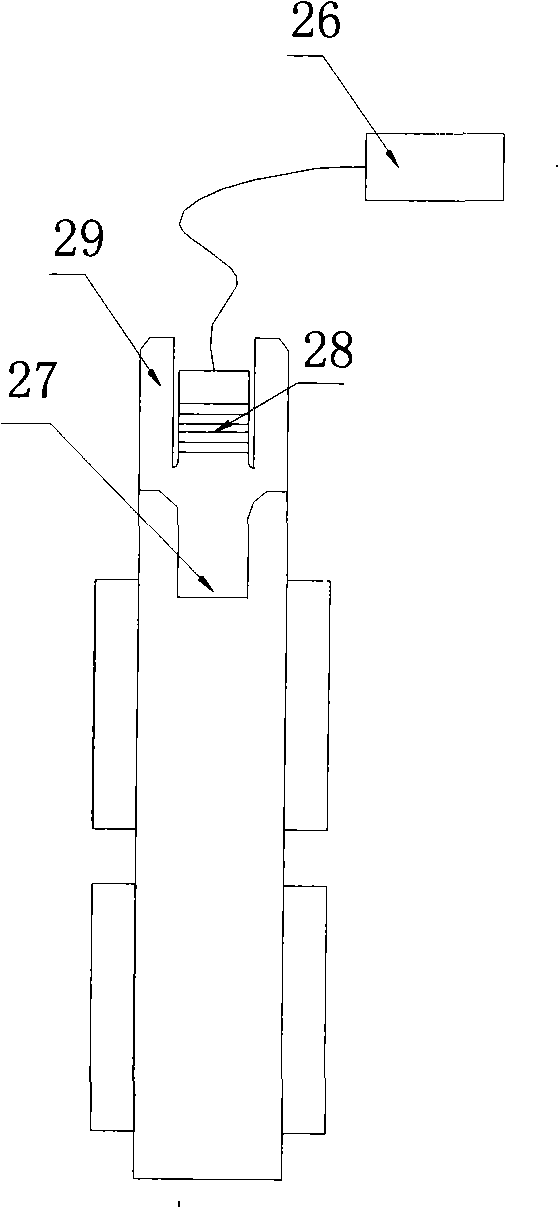

Ultrasonic reinforced subcritical water extraction method of natural product effective ingredient and device

A technology of ultrasonic strengthening and active ingredients, applied in separation methods, chemical instruments and methods, solvent extraction, etc., can solve the problems of long extraction time, low extraction efficiency, high energy consumption, shorten extraction time, easy to popularize and apply, The effect of the simple structure of the device

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment example 1

[0033] Example 1: Extraction of volatile oil from cloves

[0034] Slowly open the regulating valve of the nitrogen tank, pass the nitrogen gas into the deionized water of the reservoir, and process for about 30 minutes; weigh 0.5 kg of clove powder that has been crushed to 60 meshes, put it into a 2L extraction kettle, and set the Temperature, pressure, ultrasonic and other parameters, turn on the pre-heater and pressure pump, add about 1.5 kg of pre-heated water at a flow rate of 10ml / min, under the conditions of temperature 150°C, pressure 2MPa, ultrasonic power 100W, ultrasonic frequency 20KHz, the effect After 60min, the extract was discharged from the bottom of the extraction kettle, cooled and collected by a cooler; then 50g of sodium chloride was added to the collected extract to break the water-oil equilibrium state of the extract, and 400ml of hexane was separated hexane layer, and remove the hexane with a vacuum rotary evaporator to obtain the volatile oil of cloves;...

Embodiment example 2

[0035] Implementation Case 2: Extraction of Anthraquinones from Morinda Citrifolia Root

[0036] Slowly open the regulating valve of the nitrogen tank, pass nitrogen gas into the deionized water of the reservoir, and process for about 60 minutes; weigh 0.6 kg of Morinda officinalis powder that has been crushed to 100 meshes, put it into a 2L extraction kettle, and set up the control panel Turn on the pre-heater and pressure pump, add about 1.6 kg of pre-heated water at a flow rate of 30ml / min, under the conditions of temperature 120°C, pressure 5MPa, ultrasonic power 150W, and ultrasonic frequency 40KHz After 120 minutes of action, the extract was released from the bottom of the extraction kettle, cooled and collected by a cooler. At the same time, a comparative experiment between ultrasonically enhanced subcritical water extraction and traditional solvent method and ultrasonic-assisted extraction method was carried out. The experimental results showed that when the extraction...

Embodiment example 3

[0037] Example 3: Extraction of fennel oil from fennel leaves

[0038] Slowly open the regulating valve of the nitrogen tank, pass the nitrogen gas into the deionized water of the reservoir, and process for about 20 minutes; weigh 0.2 kg of fennel coarse powder crushed to 40 meshes, put it into a 2L extraction kettle, and set the Temperature, pressure, ultrasonic and other parameters, turn on the preheater and pressure pump, add about 1 kg of preheated water at a flow rate of 70ml / min, under the conditions of temperature 110°C, pressure 7MPa, ultrasonic power 200W, ultrasonic frequency 80KHz, the effect After 30 minutes, the extract was discharged from the bottom of the extraction kettle, cooled and collected by a cooler; then 30 g of sodium chloride and 100 ml of hexane were added to the collected extract, the hexane layer was separated, and the hexane was removed by a vacuum rotary evaporator. Alkanes can be used to obtain volatile oil; then the resulting volatile oil is ana...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com