Method for preparing SiBN(C) ceramic fibre

A technology of ceramic fiber and halosilane, which is applied in the field of preparation of high-temperature-resistant ceramic fiber, can solve problems such as unfavorable popularization and application, high activity of intermediate products, complicated process, etc., and achieve the effect of low raw material cost, reliable source, and convenient spinning

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

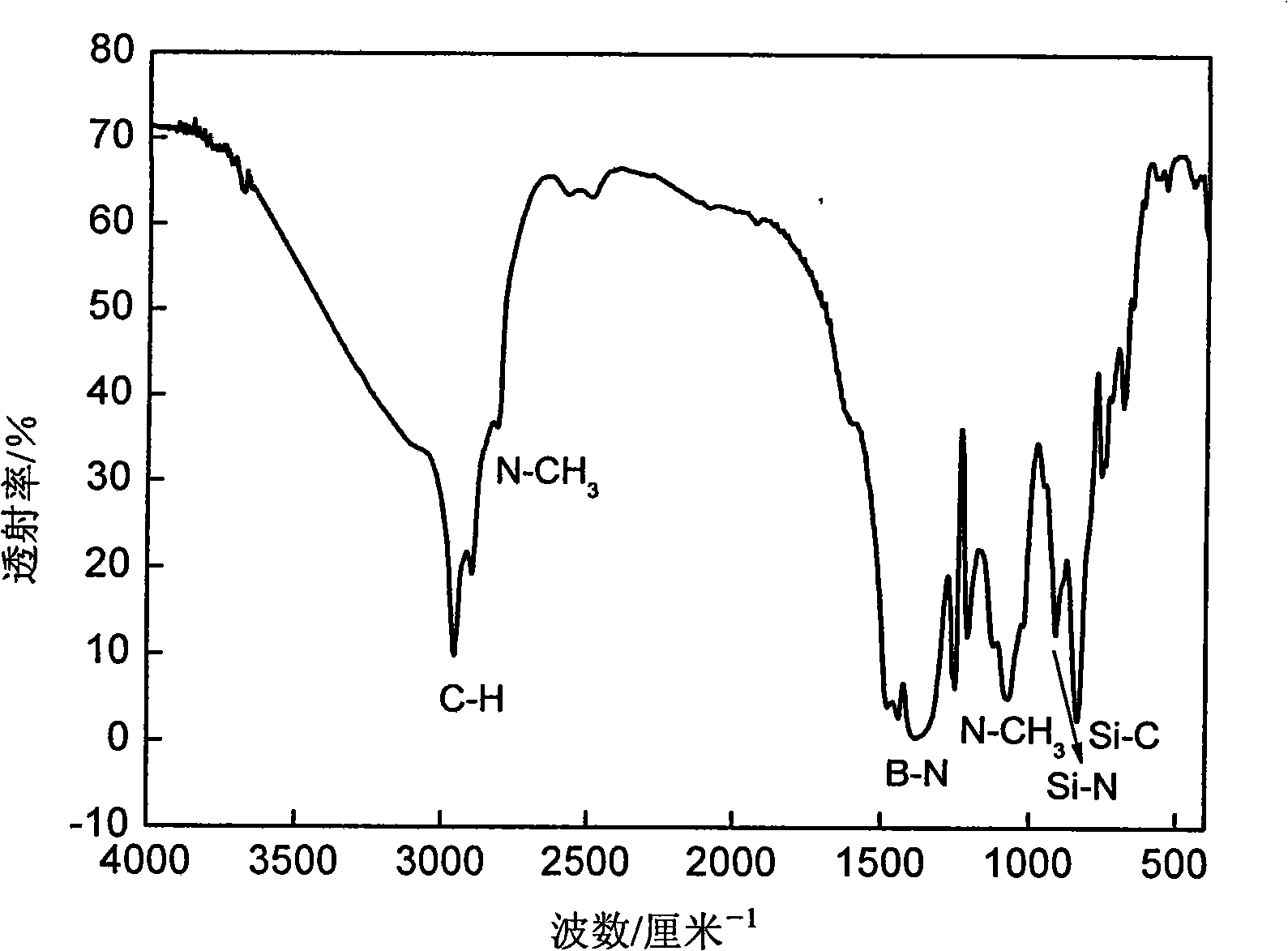

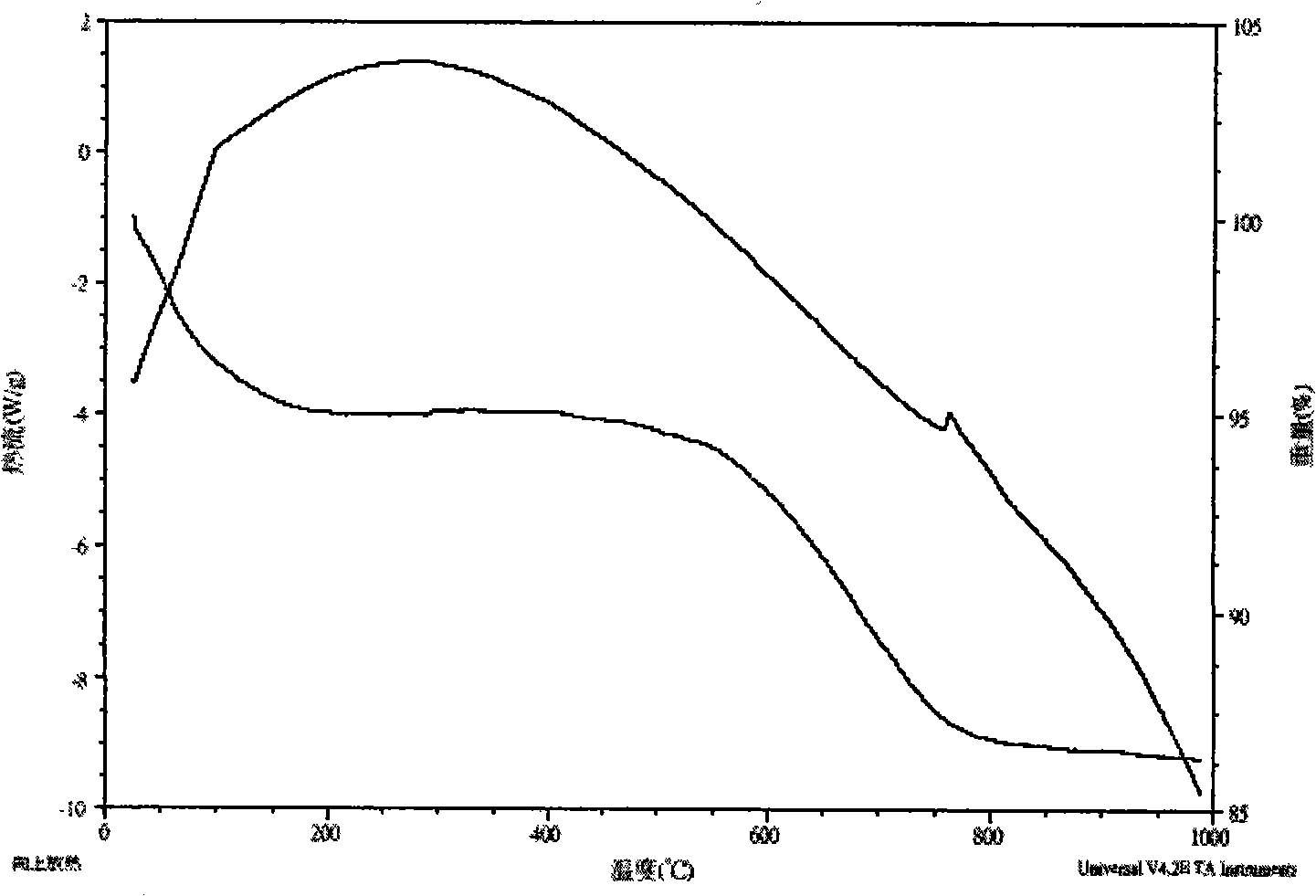

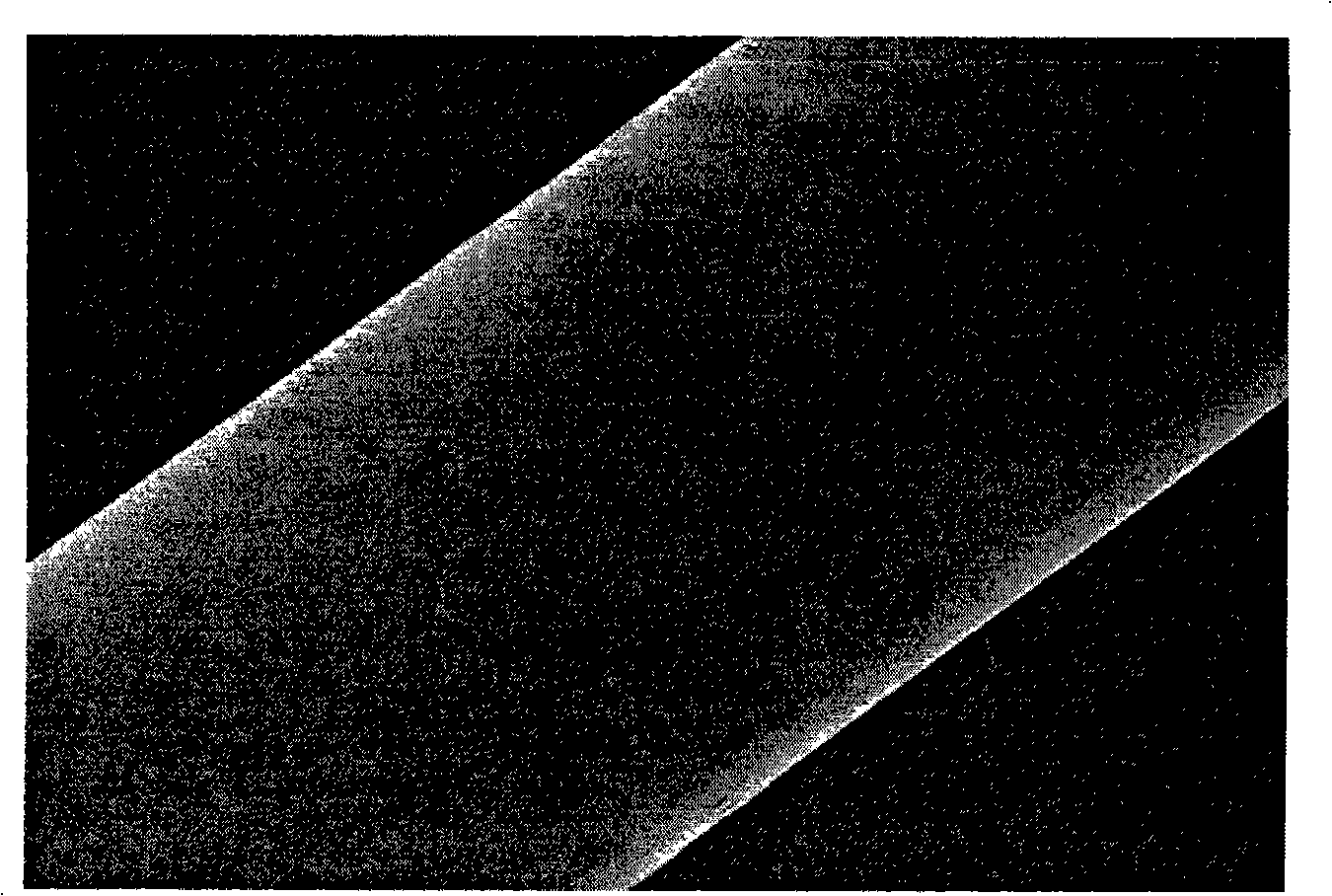

[0038](1) boron trichloride and trichlorosilane are dissolved and preserved in normal hexane; (2) vacuumize repeatedly in the 250ml there-necked flask reactor with stirring, distillation unit and constant pressure funnel, fill dry nitrogen three times, Exclude the air and moisture in it, and cool the reactor to minus 15°C; (3) Take 0.15 mol of trichlorosilane and 0.15 mol of boron trichloride into a three-necked flask protected by dry nitrogen with a syringe, and then use a syringe to Take 0.9 mol of heptamethyldisilazane and inject it into the constant pressure funnel, while stirring, add heptamethyldisilazane to the mixed solution of the first two monomers in a dropwise manner; (4) drop After the addition, the temperature was raised to 260°C at a rate of 0.5°C / min, and the temperature was kept at 260°C for 10 hours; (5) the system was cooled to 150°C, and vacuum distillation was carried out for 0.5 hours to obtain the solid polyborosilazane precursor 12.2 g; (6) Place the po...

Embodiment 2

[0045] (1) Methyl boron dichloride and silicon tetrachloride are dissolved and stored in n-hexane; (2) Repeatedly vacuumize and dry in the 500ml three-necked flask reactor with stirring, distillation device and constant pressure funnel Nitrogen four times to remove the air and moisture, and cool the reactor to minus 10°C; (3) Take 0.15 mol of silicon tetrachloride and 0.3 mol of methyl boron dichloride with a syringe and inject them into the dry nitrogen-protected In the three-necked flask, use a syringe to take 1.5 mol of N-ethylhexamethyldisilazane and inject it into the constant pressure funnel. While stirring, add N-ethylhexamethyldisilazane dropwise into the mixture of the first two monomers; (4) after the dropwise addition, the temperature was raised to 300°C at a rate of 0.5°C / min, and kept at 300°C for 12 hours; (5) the system was lowered to 165°C, and the pressure was reduced Distill for 0.5 hour to obtain 14.6 g of solid polyborosilazane precursor; (6) place the poly...

Embodiment 3

[0047] (1) phenyl dichloroborane and ethyl trichlorosilane are dissolved and stored in n-hexane; (2) before the synthesis, the 250ml three-necked flask reactor with stirring, distillation device and constant pressure funnel is repeatedly extracted Vacuum and dry nitrogen for three times to remove the air and moisture, and cool the reactor to minus 10°C; (3) Take 0.15mol of butyltrichlorosilane and 0.15mol of phenyldichloroborane into the In a three-necked flask protected by dry nitrogen, inject 1 mol of N-methylhexaethyldisilazane with a syringe into a constant pressure funnel, and while stirring, add N-methylhexaethyldisilazane dropwise (4) After the dropwise addition, the temperature was raised to 320°C at a rate of 0.3°C / min, and kept at 320°C for 12 hours; (5) The system was cooled to 182°C , Distilled under reduced pressure for 1 hour to obtain 10.8 g of solid polyborosilazane precursor; (6) place the polyborosilazane precursor obtained in step (5) in a melt spinning devi...

PUM

| Property | Measurement | Unit |

|---|---|---|

| softening point | aaaaa | aaaaa |

| softening point | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com