Composite plastic wood plate and its processing method

A plastic board and plastic wood technology, applied in chemical instruments and methods, lamination devices, lamination auxiliary operations, etc., can solve the problems of low panel strength and impact resistance, and the inability to match the strength of plastic boards, saving resources. , the effect of reducing deformation, good strength and impact resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

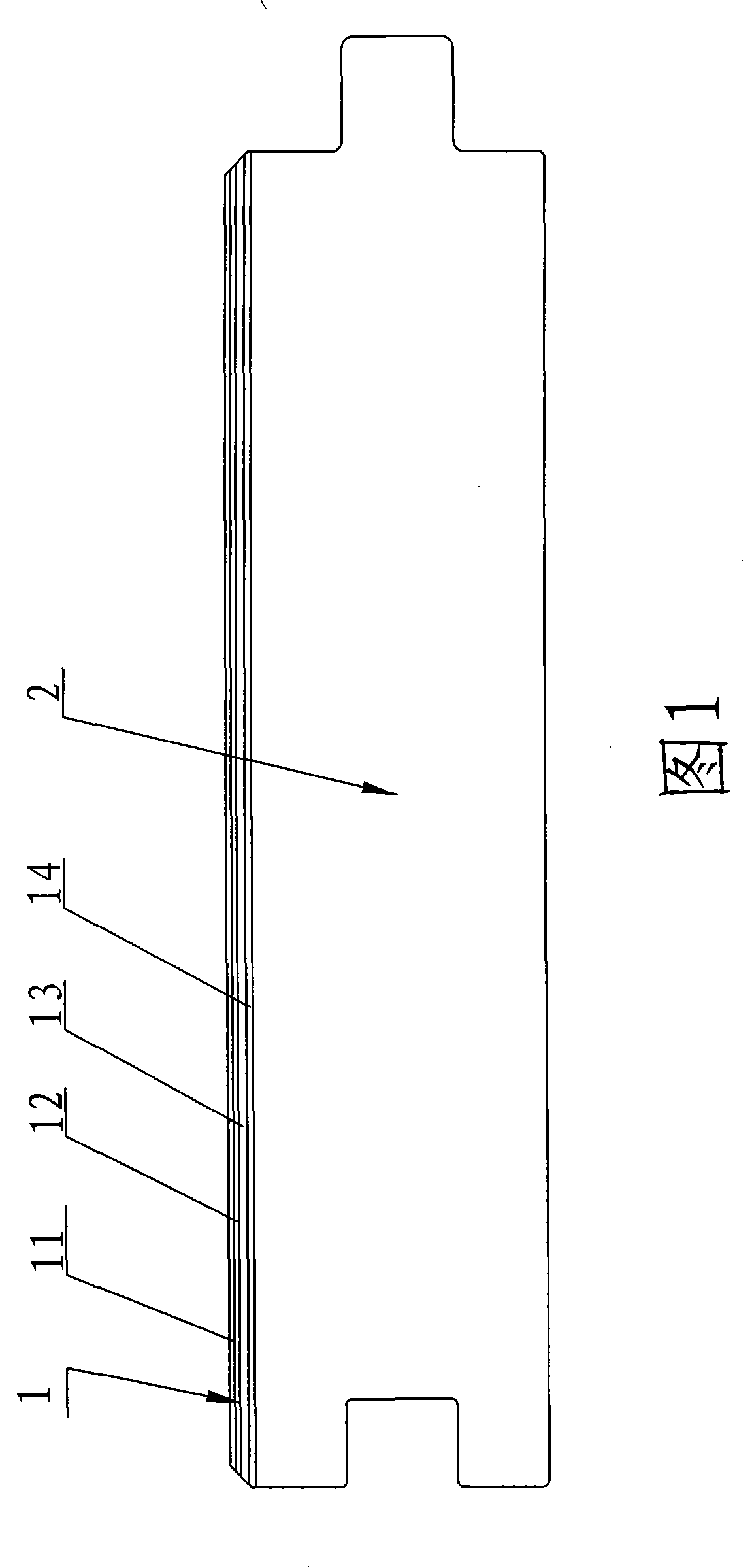

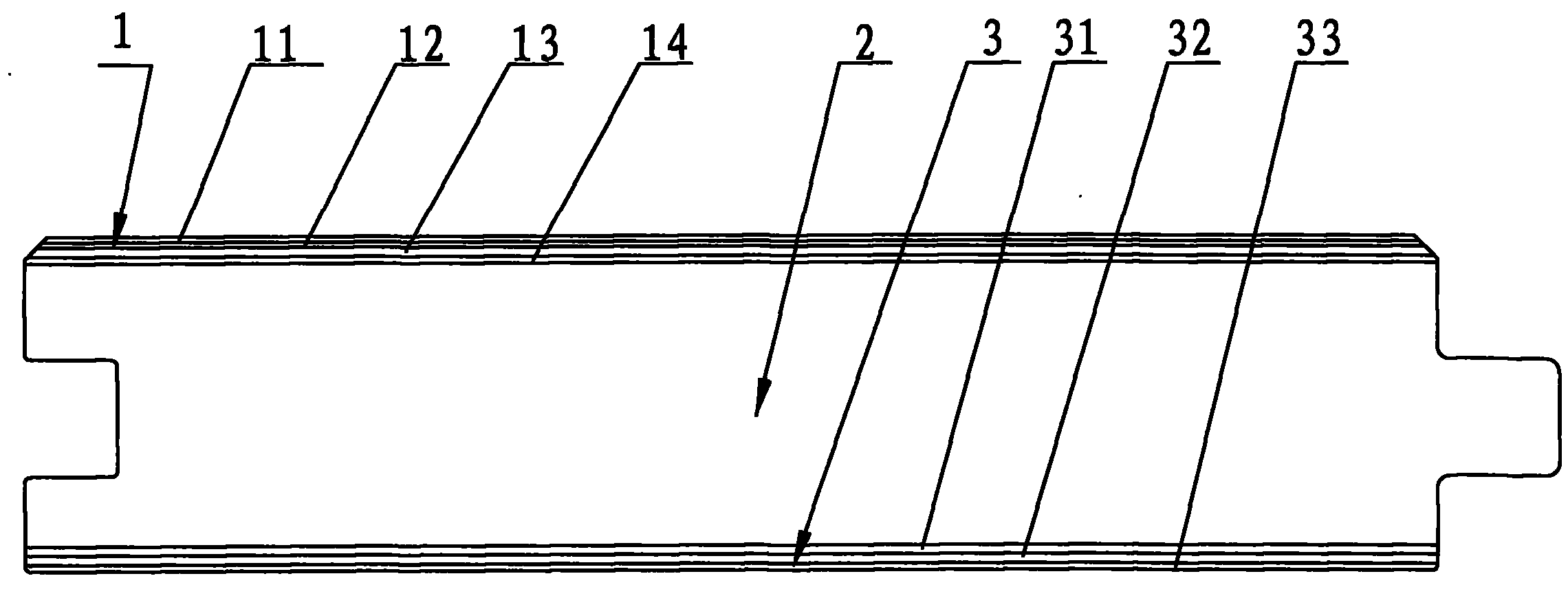

[0020] (1), make the panel

[0021] First, the wear-resistant layer, decorative layer, quartz fiber layer and polyester fiber layer are dipped in melamine glue and dried, and then the wear-resistant layer, decorative layer, quartz fiber layer and polyester fiber layer are stacked on the lower platen of the press in sequence , the upper and lower templates are pressed at a pressure of 10MPa-14MPa and a temperature of 160°C-180°C for 30s-50s, and the wear-resistant layer, decorative layer, quartz fiber layer and polyester fiber layer are hot-pressed and connected to form a panel, and naturally cooled.

[0022] (2) One side of the plastic-wood substrate is covered with glue, and the panel is attached to the plastic-wood substrate with glue, and placed on the lower template of the press. ~120min, then at 40℃~100℃, hold the pressure for 30min~60min with a pressure of 10MPa~13MPa, crimp and connect the panel and the plastic-wood substrate to form a large board, cool naturally, and c...

Embodiment 2

[0024] (1), make the panel

[0025] First, the wear-resistant layer, decorative layer, quartz fiber layer and polyester fiber layer are dipped in melamine glue and dried, and then the wear-resistant layer, decorative layer, polyester fiber layer, quartz fiber layer and polyester fiber layer are stacked in sequence on the press On the lower template, the upper and lower templates are pressed at 150°C-170°C for 30s-50s at a pressure of 14MPa-18MPa and a temperature of 150°C-170°C, and the wear-resistant layer, decorative layer, quartz fiber layer and polyester fiber layer are hot-pressed and connected to form a panel , natural cooling.

[0026] (2), pressing compound

[0027] The plastic-wood substrate is covered with glue on one side, and the panel is attached to the plastic-wood substrate surface, and placed on the lower template of the press. At 40°C-100°C, keep the pressure at 12MPa-15MPa for 20min-40min, crimp the panel and the plastic-wood substrate to form a large board...

Embodiment 3

[0029] (1), make the panel

[0030] First, the wear-resistant layer, decorative layer, quartz fiber layer and polyester fiber layer are dipped in melamine glue and dried, and then the wear-resistant layer, decorative layer, quartz fiber layer and polyester fiber layer are stacked on the lower platen of the press in sequence , the upper and lower templates are pressed at a pressure of 15MPa-18MPa and a temperature of 150°C-160°C for 30s-50s, and the wear-resistant layer, decorative layer, quartz fiber layer and polyester fiber layer are hot-pressed and connected to form a panel, and cooled naturally.

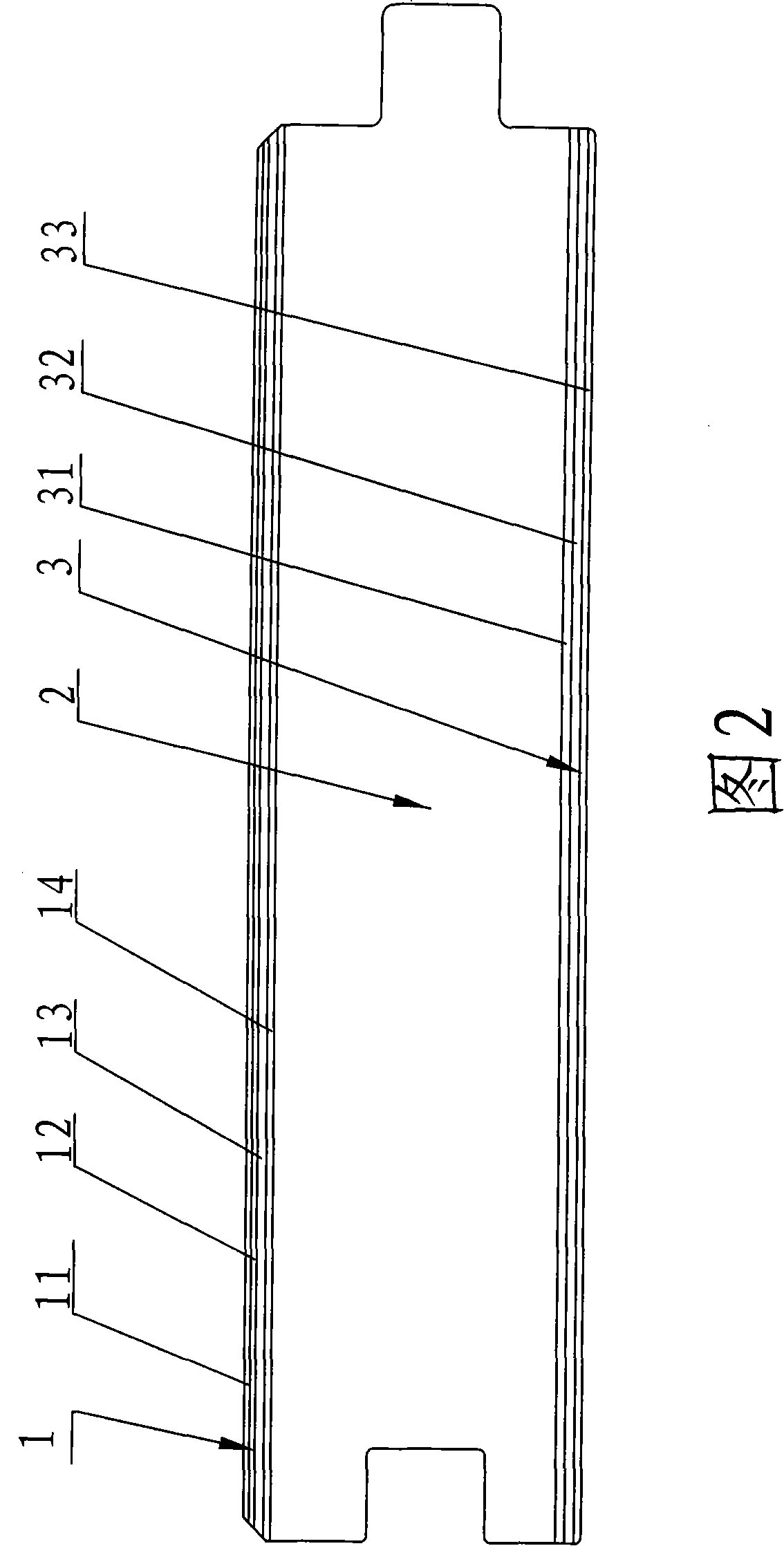

[0031] (2), make the bottom plate

[0032] Dip the polyester fiber layer, quartz fiber layer and balance layer in melamine glue and dry them, then stack the polyester fiber layer, quartz fiber layer and balance layer on the lower platen of the press in sequence, and the The pressure and temperature are maintained at 150°C to 160°C for 30s to 50s, and the polyester fiber layer, q...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com