Nano-catalyst suitable for slurry condition bed, production method and application thereof

A nano-catalyst, slurry bed technology, applied in physical/chemical process catalysts, metal/metal oxide/metal hydroxide catalysts, hydrocarbon production from carbon oxides, etc. Simple process, controllable conditions and highly selective effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment example 1

[0016] 10g Co(NO3) 2 .6H 2 O is dissolved in 1000ml hexanol and heated to reflux at 180℃ for 3 hours to obtain 5-10nm Co 3 O 4 Nanoparticles in hexanol solution.

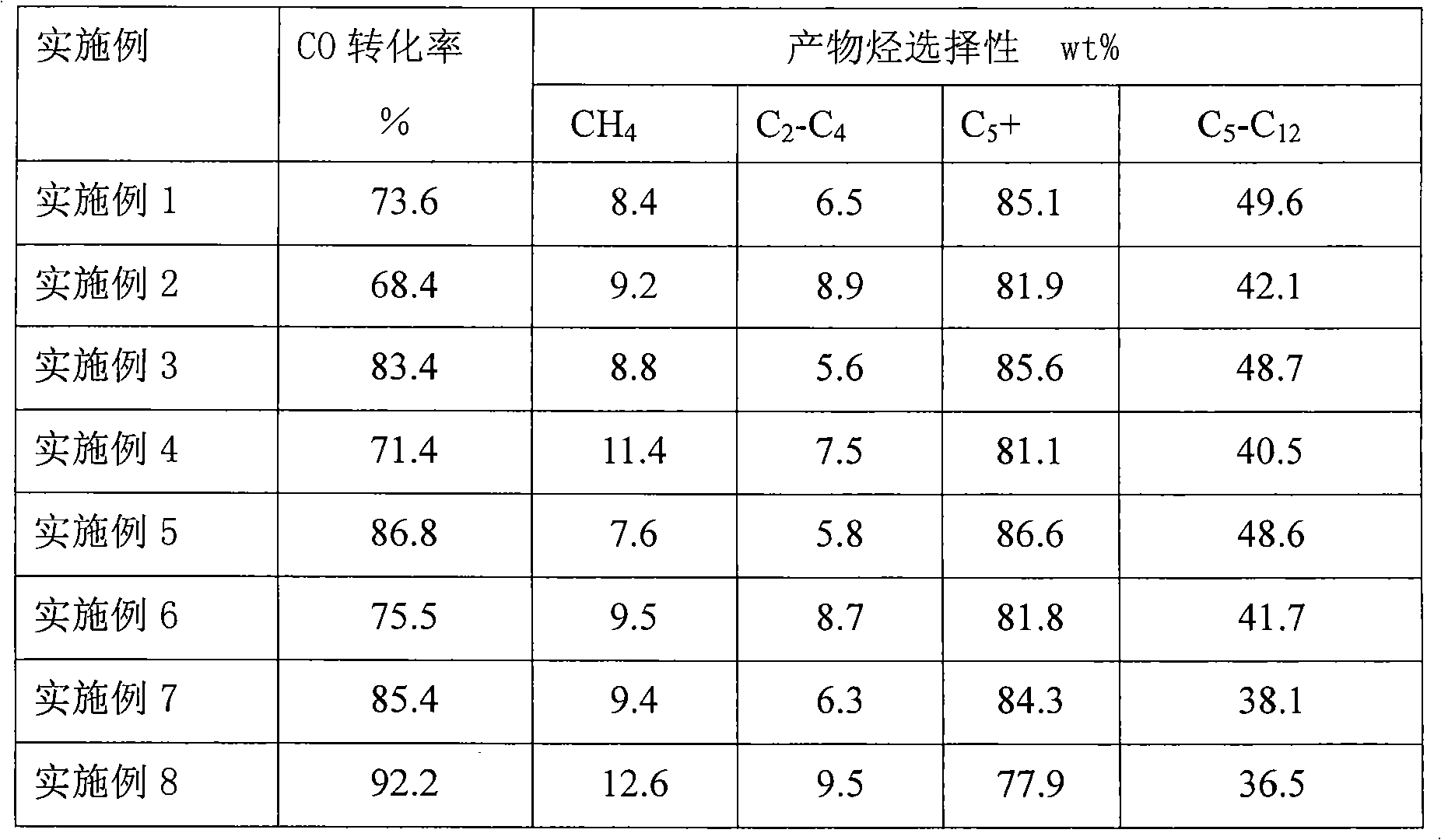

[0017] Take the above 200ml containing Co 3 O 4 The hexanol solution of nanoparticles was put into a 1L slurry stirred tank, and the temperature was programmed and reduced in pure hydrogen. The reduction conditions were 300℃, 0.2MPa, 1200h -1 (V / V), 800rpm, 10h. After reduction, the temperature is lowered and switched to syngas for reaction. The reaction conditions are 190℃, 2MPa, 1200h -1 (V / V), 800rpm, H 2 / CO=2 / 1. In order to ensure that the Fischer-Tropsch synthesis reaction enters a steady state, a transition operation for more than 24 hours is required to consider the reaction system to enter a steady state operation. Product CO, CO 2 , CH 4 And H 2 Detect with carbon molecular sieve column and TCD, detect gaseous hydrocarbon with Porapak-Q column and FID, and detect oil and wax samples with OV-101 capillary colum...

Embodiment example 2

[0019] 10g Fe(NO 3 ) 2 .6H 2 O is dissolved in 500ml hexanol and heated to reflux at 180℃ for 4 hours to obtain 10-20nm Fe 2 O 3 Nanoparticles in hexanol solution.

[0020] Take the above 200ml containing Fe 2 O 3 The hexanol solution of nanoparticles is put into a 1L slurry stirred tank, and the temperature is programmed to reduce in the synthesis gas. The reduction conditions are 350℃, 0.5MPa, 1000h -1 (V / V), 800rpm, 12h. After reduction, the temperature is lowered for reaction, and the reaction conditions are 210℃, 2MPa, 1200h -1 (V / V), 800rpm, H 2 / CO=1.2 / 1. The catalytic reaction performance evaluation is listed in Table 1.

Embodiment example 3

[0022] 6g Co(NO3) 2 .6H 2 O was dissolved in 300ml of octanol and heated at 190°C under reflux for 3 hours to obtain 60-80nm Co dispersed in octanol 3 O 4 Particles.

[0023] Take the above 200ml containing Co 3 O 4 The octanol solution of nanoparticles was put into a 1L slurry stirred tank, and the temperature was programmed and reduced in the synthesis gas. The reduction conditions were 400℃, 0.2MPa, 500h -1 (V / V), 500rpm, 18h. After reduction, the temperature is lowered for reaction, and the reaction conditions are 200℃, 1.2MPa, 500h -1 (V / V), 500rpm, H 2 / CO=2.5 / 1. The catalytic reaction performance evaluation is listed in Table 1.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com