Hollow fiber compound film with ultra-thin active layer, preparation method and application thereof

A fiber composite and active layer technology, applied in chemical instruments and methods, membrane technology, semi-permeable membrane separation, etc., can solve the problems of difficult ultra-thin active skin layer, complicated method process, complex realization process, etc., to achieve membrane production The effect of low cost, simple preparation process and abundant sources

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

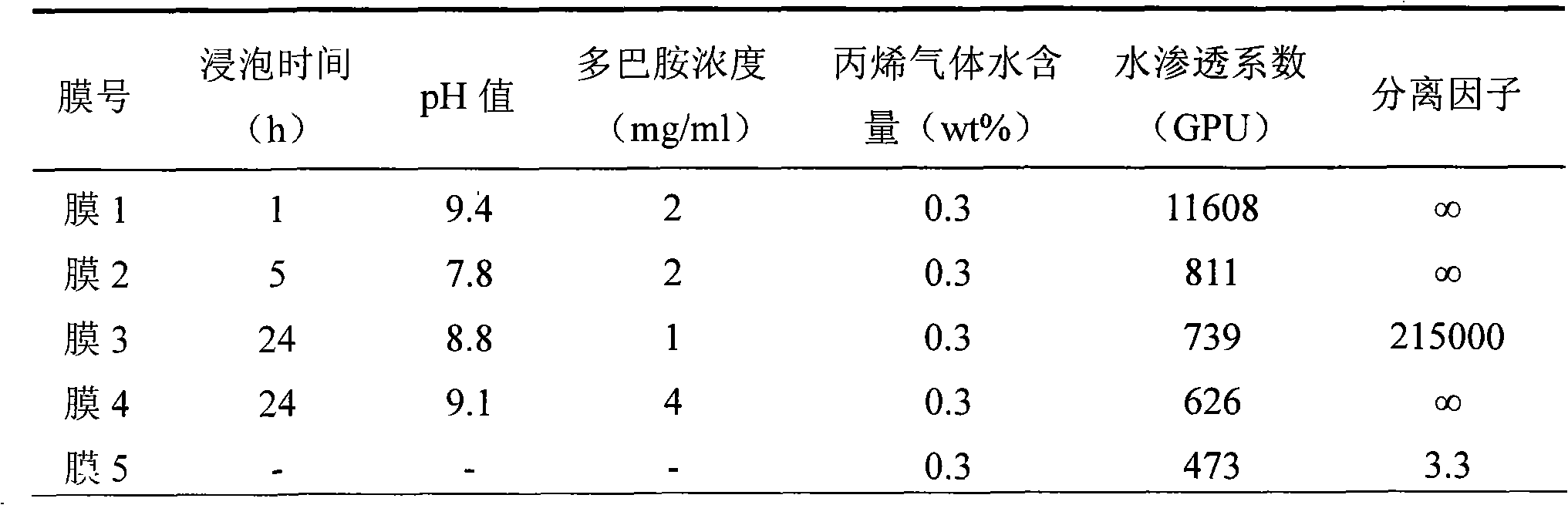

Embodiment 1

[0013] Soak a polysulfone hollow fiber membrane with a molecular weight cut off of 6000, an outer diameter of 340 μm, and an inner diameter of 130 μm in deionized water for 24 hours, then soak it in 0.5mol / L hydrochloric acid solution for 0.5 hour, take it out and dry it for later use; use 0.5mol / L The hydrochloric acid modulation pH value is 9.4, and concentration is the 500mlTris-HCl buffer solution of 0.1mol / L; Then add dopamine hydrochloride to make 2mg / ml solution; Soak the polysulfone hollow fiber support layer in the solution for 1 hour to obtain polydopamine / Polysulfone hollow fiber composite membrane (membrane 1).

[0014] The thickness of the polydopamine separation layer of the prepared membrane 1 was measured to be 16 nm by a profilometer. It is used to separate propylene-water mixed gas with a water mass concentration of 0.3wt%, the permeability coefficient of water can reach 11608GPU, and the separation factor of water to propylene is infinite.

Embodiment 2

[0016] Soak a polysulfone hollow fiber membrane with a molecular weight cut off of 6000, an outer diameter of 340 μm, and an inner diameter of 130 μm in deionized water for 24 hours, then soak it in 0.5mol / L hydrochloric acid solution for 0.5 hour, take it out and dry it for later use; use 0.5mol / L The hydrochloric acid modulation pH value is 7.8, and concentration is the 500mlTris-HCl damping fluid of 0.1mol / L; Add dopamine hydrochloride to make 2mg / ml solution then; Soak the polysulfone hollow fiber supporting layer in the solution for 5 hours, obtain polydopamine / Polysulfone hollow fiber composite membrane (membrane 2).

[0017] The thickness of the polydopamine separation layer of the prepared membrane 1 was measured to be 45 nm by a profilometer. It is used to separate propylene-water mixed gas with a water mass concentration of 0.3wt%, the permeability coefficient of water can reach 811GPU, and the separation factor of water to propylene is infinite.

Embodiment 3

[0019] Soak a polysulfone hollow fiber membrane with a molecular weight cut off of 6000, an outer diameter of 340 μm, and an inner diameter of 130 μm in deionized water for 24 hours, then soak it in 0.5mol / L hydrochloric acid solution for 0.5 hour, take it out and dry it for later use; use 0.5mol / L The hydrochloric acid modulation pH value is 8.8, and concentration is the 500mlTris-HCl damping solution of 0.1mol / L; Then add dopamine hydrochloride and make 1mg / ml solution; Soak the polysulfone hollow fiber support layer in the solution for 24 hours, obtain polydopamine / Polysulfone hollow fiber composite membrane (membrane 3).

[0020] The thickness of the polydopamine separation layer of the prepared membrane 1 was measured to be 60 nm by a profilometer. Used to separate propylene-water mixture gas with a water mass concentration of 0.3wt%, the permeability coefficient of water can reach 739.4GPU, and the separation factor of water to propylene is 215,000.

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com