Inner arced ceiling thin wall straining cartridge throw-in type optical fibre Bragg grating pressure sensor

A technology of pressure sensor and strain tube, which is applied in the direction of fluid pressure measurement, measurement of fluid pressure, and instruments using optical methods, which can solve the needs of large pressure measurement ranges, Bragg gratings are easy to interfere with each other, and sensors can no longer be accurate Measurement and other issues, to reduce mutual interference, improve the measurement range, the effect of uniform force

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

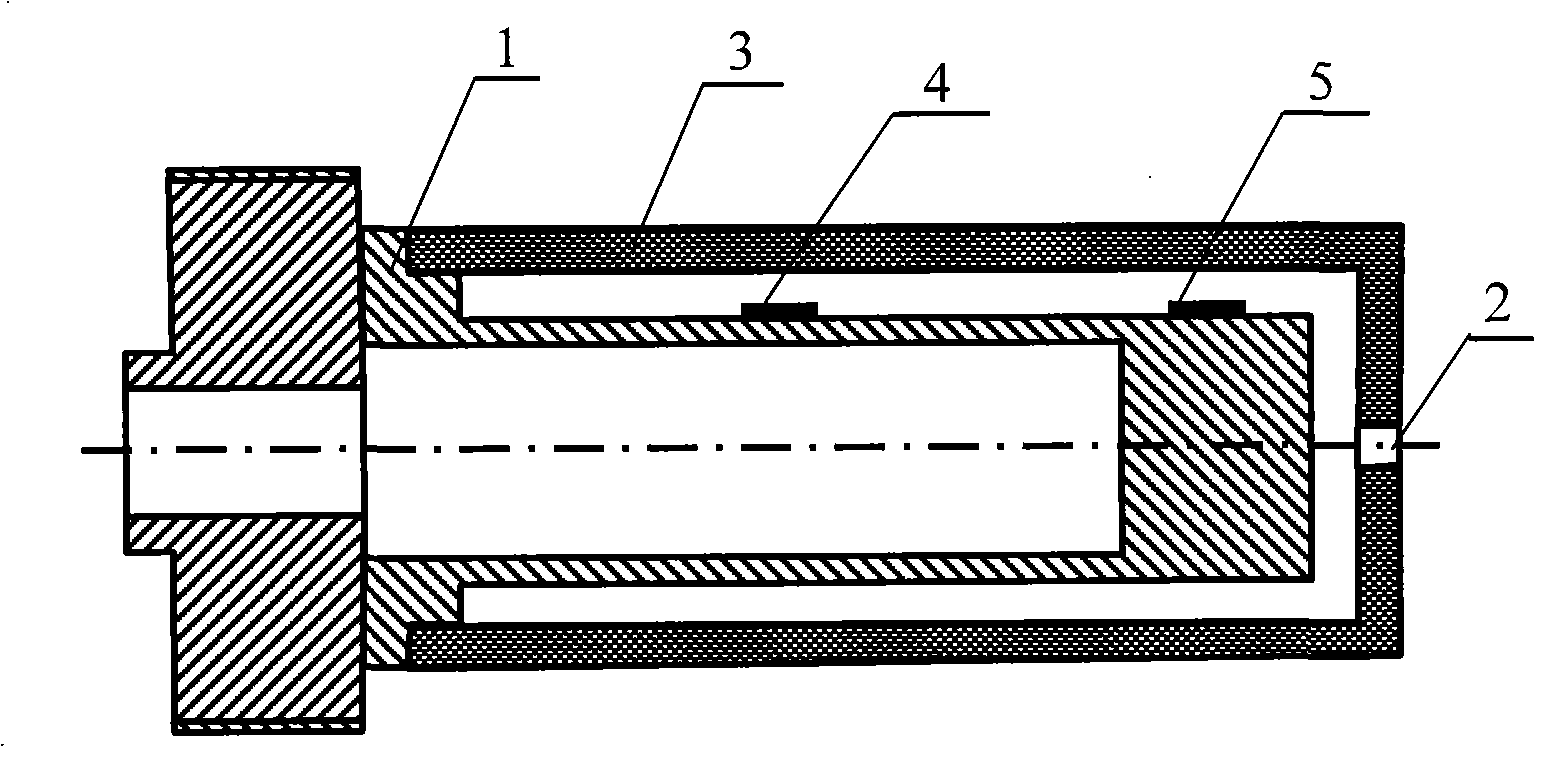

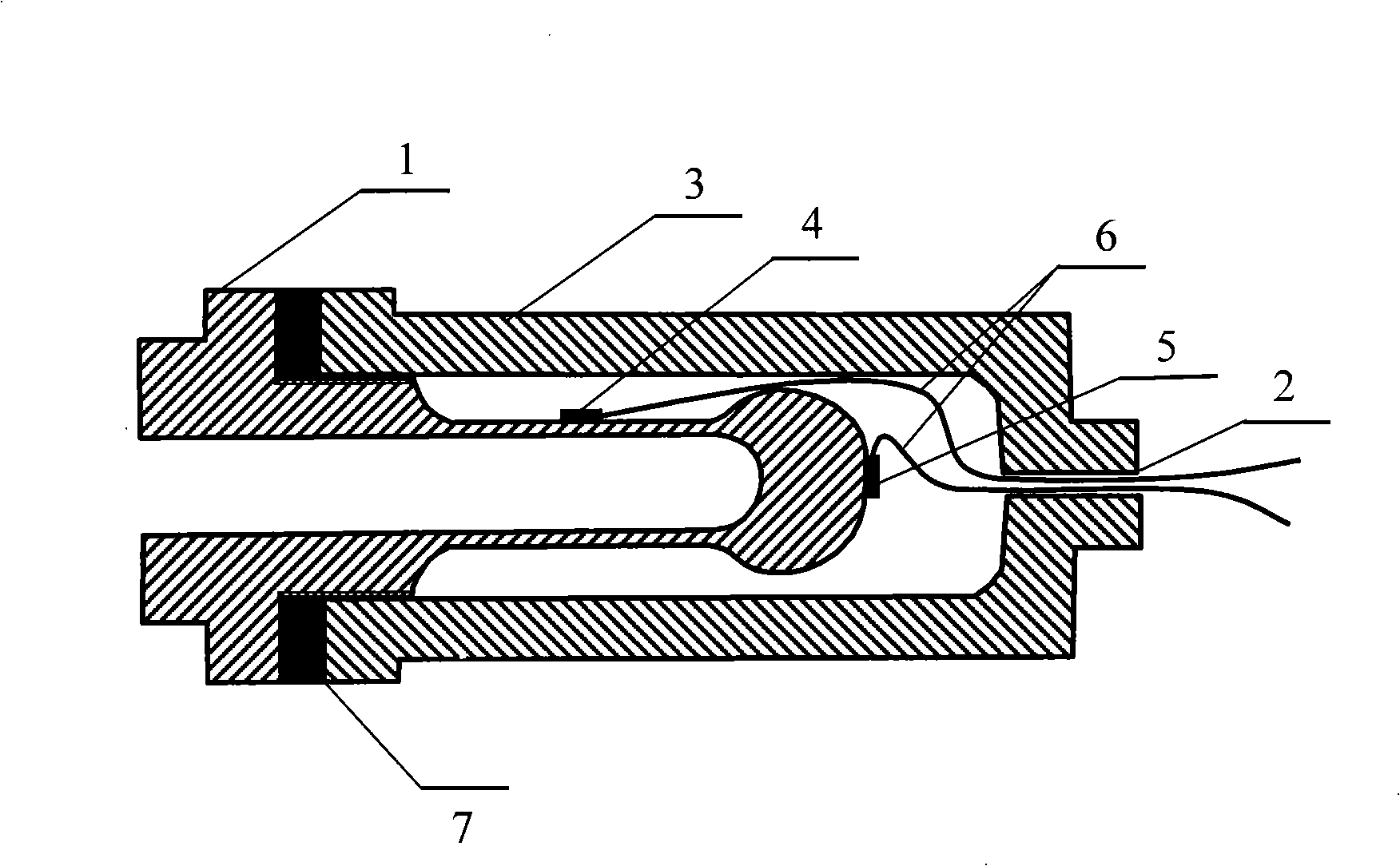

[0016] Inner curved top and outer flat top thin-walled strain tube input fiber Bragg grating pressure sensor. Inner curved top and outer flat top thin-walled strain tube input fiber Bragg grating pressure sensor such as figure 2 As shown, this sensor consists of a metal thin-walled inner cylinder 1, a metal thick-walled outer cylinder 3 with an optical fiber exit hole 2, a pressure measurement fiber Bragg grating 4, a temperature compensation fiber Bragg grating 5, and two signal-leading single-mode fibers 6 It is composed of sealing gasket 7 and other components, and is characterized in that the inner top of the metal thin-walled inner cylinder 1 is an arc-shaped structure, and the outer top is a flat top structure; the metal thin-walled inner cylinder 1 and the metal thick-walled outer tube with an optical fiber outlet The barrel 3 is made of stainless steel; the pressure measuring fiber Bragg grating 4 and the temperature compensating fiber Bragg grating 5 are packaged in ...

Embodiment 2

[0018] Thin-walled strain cylinder with inner and outer curved tops is an input-type optical fiber Bragg grating pressure sensor. Thin-walled strain cylinder with inner and outer curved top input type fiber Bragg grating pressure sensor such as image 3 As shown, this sensor is compared with the input-type optical fiber Bragg grating pressure sensor of the inner arc-shaped top and outer flat-top thin-walled strain cylinder of embodiment 1. It is characterized in that the outer top of the metal thin-walled inner cylinder 1 is also an arc-shaped structure, and the rest Parts are the same. The advantage of this sensor is that it makes the top internal force of the metal thin-walled inner cylinder 1 more uniform, further makes up for the defect that the local pressure at the corner of the top is too high and easy to be damaged, and improves the pressure measurement range.

Embodiment 3

[0020] An aluminum inner curved top thin-walled strain tube input type optical fiber Bragg grating pressure sensor, this sensor can be the inner arc top outer flat top thin wall strain tube input type optical fiber Bragg grating pressure sensor shown in embodiment 1, or It is the input-type optical fiber Bragg grating pressure sensor of the inner and outer curved top thin-wall strain cylinder shown in embodiment 2, and it is characterized in that the metal thin-wall inner cylinder 1 is made of aluminum material; because the aluminum material has good ductility, The strain under pressure is relatively sensitive, so this type of sensor has a high pressure responsiveness; and because the tensile strength of aluminum material is low, the sensor with aluminum structure is suitable for pressure measurement in a lower pressure range.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com